Nickel anodes serve as the positive electrode in electrochemical cells, facilitating oxidation reactions and releasing electrons during the charging process. Nickel cathodes function as the negative electrode, where reduction reactions occur and electrons are absorbed to complete the circuit. The distinct roles of nickel anode and nickel cathode directly impact the efficiency and stability of batteries in nickel-based energy storage systems.

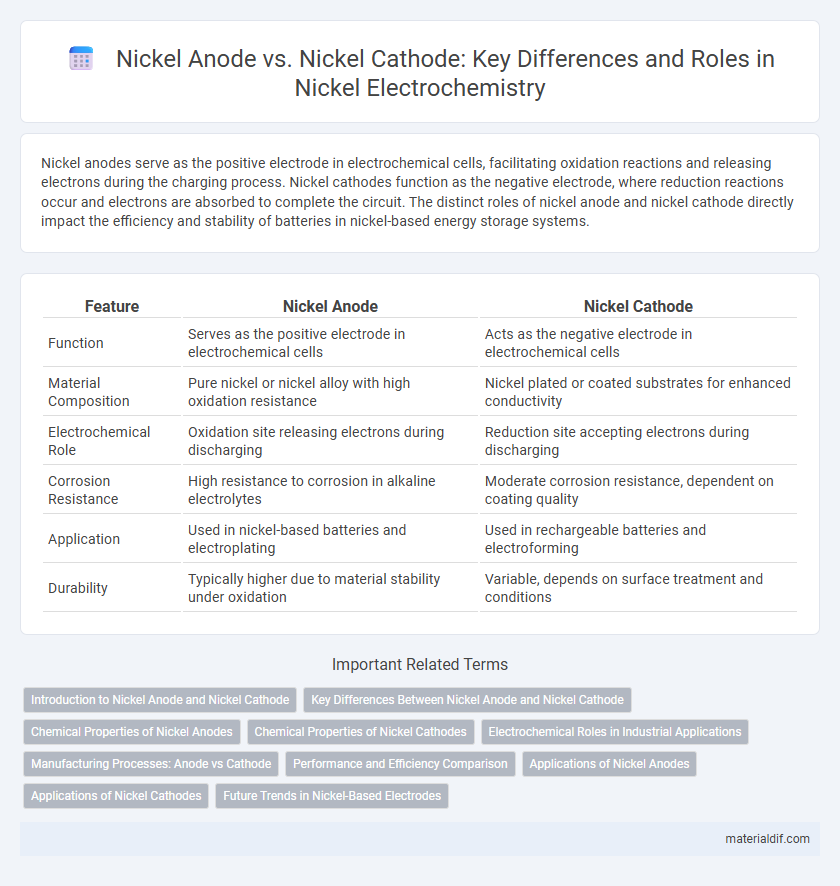

Table of Comparison

| Feature | Nickel Anode | Nickel Cathode |

|---|---|---|

| Function | Serves as the positive electrode in electrochemical cells | Acts as the negative electrode in electrochemical cells |

| Material Composition | Pure nickel or nickel alloy with high oxidation resistance | Nickel plated or coated substrates for enhanced conductivity |

| Electrochemical Role | Oxidation site releasing electrons during discharging | Reduction site accepting electrons during discharging |

| Corrosion Resistance | High resistance to corrosion in alkaline electrolytes | Moderate corrosion resistance, dependent on coating quality |

| Application | Used in nickel-based batteries and electroplating | Used in rechargeable batteries and electroforming |

| Durability | Typically higher due to material stability under oxidation | Variable, depends on surface treatment and conditions |

Introduction to Nickel Anode and Nickel Cathode

Nickel anodes serve as the positive electrodes in electroplating and electrolysis, where they undergo oxidation to release nickel ions into the electrolyte solution. Nickel cathodes act as the negative electrodes, attracting nickel ions from the electrolyte to deposit pure nickel metal, ensuring high-purity nickel recovery. Key parameters influencing both nickel anode and cathode performance include current density, electrolyte composition, and temperature control.

Key Differences Between Nickel Anode and Nickel Cathode

Nickel anodes serve as the positive electrode in electrochemical cells, undergoing oxidation and releasing nickel ions into the electrolyte, while nickel cathodes act as the negative electrode, facilitating the reduction process and nickel ion deposition. The structural composition of nickel anodes typically involves porous or sintered forms to maximize surface area for oxidation, whereas nickel cathodes are designed for high conductivity and durability to efficiently collect plated nickel. Electrochemical performance differences manifest in their roles with anodes influencing cell efficiency through oxidation rates and cathodes determining deposition quality and battery lifespan.

Chemical Properties of Nickel Anodes

Nickel anodes exhibit strong chemical resistance due to their stable oxide layer, which enhances corrosion resistance in electrochemical cells. These anodes facilitate efficient electron transfer through their high electrical conductivity and catalytic activity in redox reactions. Their robustness in alkaline and acidic environments makes nickel anodes essential for industrial electroplating and battery applications.

Chemical Properties of Nickel Cathodes

Nickel cathodes exhibit superior electrochemical stability compared to nickel anodes, making them essential in high-performance batteries and electroplating processes. Their chemical properties include excellent corrosion resistance and catalytic activity, which enhance electron transfer efficiency during reduction reactions. The dense, pure nickel structure of cathodes ensures minimal impurity interference, supporting consistent conductivity and durability in industrial applications.

Electrochemical Roles in Industrial Applications

Nickel anodes serve as the source of nickel ions during electroplating, undergoing oxidation to release Ni2+ into the electrolyte solution. Nickel cathodes function by reducing nickel ions from the electrolyte, facilitating metal deposition through electrochemical reduction. This anodic and cathodic synergy is crucial in industrial applications like battery manufacturing and electro-refining, ensuring efficient metal recovery and coating quality.

Manufacturing Processes: Anode vs Cathode

Nickel anode manufacturing involves electroplating or electroforming where pure nickel is deposited onto a substrate through controlled electrochemical reactions, ensuring uniform thickness and high purity essential for battery performance. Nickel cathode production typically requires powder synthesis followed by sintering or coating onto current collectors, optimizing particle size and surface area to enhance electrochemical activity and durability. Both processes emphasize strict control over impurity levels and microstructure to meet specific application demands in batteries and industrial applications.

Performance and Efficiency Comparison

Nickel anodes exhibit higher oxidation resistance and longer operational lifespans, enhancing battery durability and energy density. Nickel cathodes offer superior electrochemical stability and yield greater charge capacity, improving overall battery efficiency. Comparing both, nickel cathodes generally provide enhanced performance in energy storage applications, while nickel anodes contribute to longer cycle life and stability under high current conditions.

Applications of Nickel Anodes

Nickel anodes serve as essential components in electroplating, battery manufacturing, and electroforming applications due to their high conductivity and corrosion resistance. They provide a controlled source of nickel ions in electrolytic cells, enhancing the uniformity and adhesion of metal coatings in industries like automotive, electronics, and aerospace. Their robust performance under harsh chemical environments makes nickel anodes preferred for nickel-based electrodeposition processes and rechargeable battery electrodes.

Applications of Nickel Cathodes

Nickel cathodes are extensively utilized in electroplating, battery manufacturing, and chemical synthesis due to their high purity and excellent conductivity. These cathodes serve as a critical component in nickel-metal hydride (NiMH) and lithium-ion batteries, enhancing energy storage efficiency and cycle life. Industrial applications also leverage nickel cathodes for producing high-quality nickel alloys and catalysts in hydrogenation reactions.

Future Trends in Nickel-Based Electrodes

Future trends in nickel-based electrodes emphasize enhanced energy density and improved cycle life for both nickel anodes and cathodes, driven by advances in nanostructured materials and surface coatings. Innovations in nickel-rich cathodes, such as NMC (Nickel Manganese Cobalt) and nickel-cobalt-aluminum (NCA) chemistries, are aimed at maximizing capacity and stability for electric vehicle batteries. Research into nickel anodes focuses on minimizing dendrite formation and increasing efficiency, leveraging solid-state electrolytes and alloying techniques to enable safer, longer-lasting battery technologies.

Nickel Anode vs Nickel Cathode Infographic

materialdif.com

materialdif.com