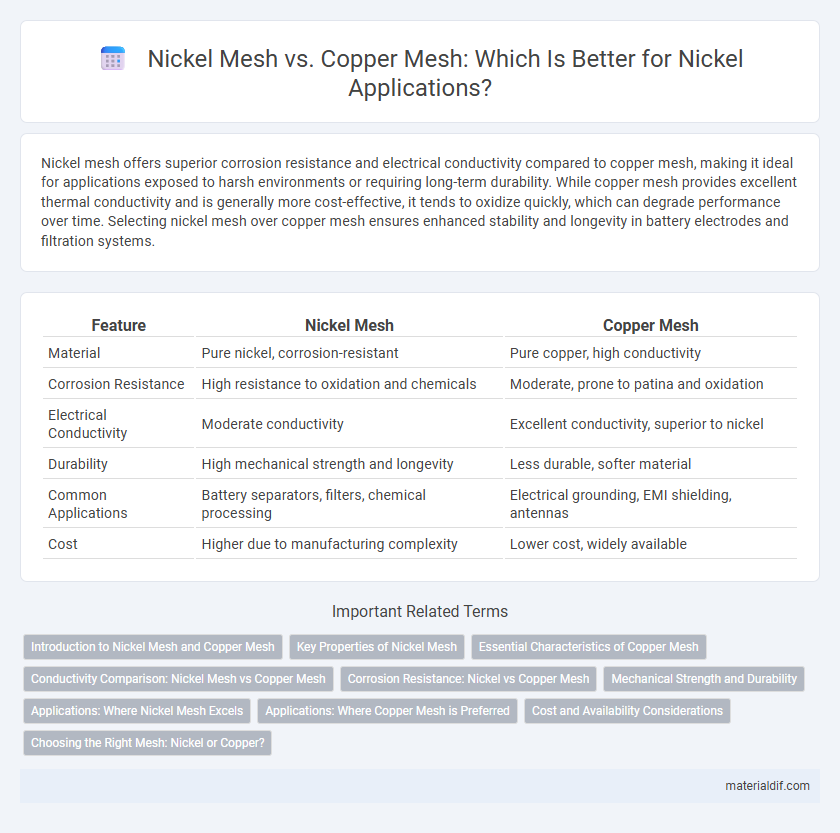

Nickel mesh offers superior corrosion resistance and electrical conductivity compared to copper mesh, making it ideal for applications exposed to harsh environments or requiring long-term durability. While copper mesh provides excellent thermal conductivity and is generally more cost-effective, it tends to oxidize quickly, which can degrade performance over time. Selecting nickel mesh over copper mesh ensures enhanced stability and longevity in battery electrodes and filtration systems.

Table of Comparison

| Feature | Nickel Mesh | Copper Mesh |

|---|---|---|

| Material | Pure nickel, corrosion-resistant | Pure copper, high conductivity |

| Corrosion Resistance | High resistance to oxidation and chemicals | Moderate, prone to patina and oxidation |

| Electrical Conductivity | Moderate conductivity | Excellent conductivity, superior to nickel |

| Durability | High mechanical strength and longevity | Less durable, softer material |

| Common Applications | Battery separators, filters, chemical processing | Electrical grounding, EMI shielding, antennas |

| Cost | Higher due to manufacturing complexity | Lower cost, widely available |

Introduction to Nickel Mesh and Copper Mesh

Nickel mesh and copper mesh are widely used materials in filtration, shielding, and battery applications due to their excellent conductivity and corrosion resistance. Nickel mesh offers superior chemical stability and higher resistance to oxidation at elevated temperatures compared to copper mesh, making it ideal for harsh environments. Copper mesh provides excellent electrical conductivity and is cost-effective, but it requires protective coatings to prevent corrosion in moist or acidic conditions.

Key Properties of Nickel Mesh

Nickel mesh exhibits superior corrosion resistance and excellent thermal stability compared to copper mesh, making it ideal for harsh environments and high-temperature applications. Its high tensile strength and durability ensure long-lasting structural integrity, while its catalytic properties enhance performance in electrochemical processes. Nickel mesh also provides better resistance to oxidation and chemical attacks, extending its lifespan in industrial filtration and battery technologies.

Essential Characteristics of Copper Mesh

Copper mesh exhibits high electrical conductivity and exceptional corrosion resistance, making it ideal for electromagnetic interference (EMI) shielding and grounding applications. Its superior thermal conductivity allows efficient heat dissipation, which is crucial in electronic and industrial environments. Compared to nickel mesh, copper mesh offers greater flexibility and easier solderability, enhancing its usability in various manufacturing processes.

Conductivity Comparison: Nickel Mesh vs Copper Mesh

Nickel mesh exhibits lower electrical conductivity, approximately 14% IACS (International Annealed Copper Standard), compared to copper mesh which boasts about 100% IACS, making copper significantly more efficient for electrical applications. The higher conductivity of copper mesh reduces resistive losses and improves current flow, ideal for electromagnetic shielding and electronic device components. Nickel mesh, while less conductive, offers superior corrosion resistance and mechanical strength, suitable for environments where durability outweighs conductivity demands.

Corrosion Resistance: Nickel vs Copper Mesh

Nickel mesh offers superior corrosion resistance compared to copper mesh, making it ideal for applications in harsh chemical environments and marine settings. Copper mesh is prone to oxidation and develops a green patina when exposed to moisture and air, which can degrade its performance over time. The robust corrosion resistance of nickel mesh extends the lifespan of filtration systems and electrochemical cells, ensuring consistent conductivity and structural integrity.

Mechanical Strength and Durability

Nickel mesh exhibits superior mechanical strength compared to copper mesh, making it more resistant to deformation and mechanical stress in industrial applications. Its enhanced durability stems from excellent corrosion resistance and high melting point, ensuring longevity under harsh environmental conditions. Copper mesh, while conductive, tends to wear faster due to softer properties and susceptibility to oxidation, reducing its lifespan in demanding mechanical environments.

Applications: Where Nickel Mesh Excels

Nickel mesh excels in high-temperature and corrosive environments due to its superior oxidation resistance and durability compared to copper mesh. It is widely used in industrial filtration, battery electrodes, and electroplating processes where chemical stability and mechanical strength are critical. Nickel mesh's excellent electrical conductivity combined with its resistance to acid and alkali solutions makes it ideal for harsh chemical processing and advanced energy storage applications.

Applications: Where Copper Mesh is Preferred

Copper mesh is preferred in applications requiring superior electrical conductivity and corrosion resistance, such as electromagnetic shielding in electronic devices and grounding systems. Its excellent thermal conductivity also makes it ideal for heat dissipation in batteries and circuits. Unlike nickel mesh, copper mesh is favored in environments where enhanced conductivity improves performance and longevity.

Cost and Availability Considerations

Nickel mesh typically costs more than copper mesh due to the higher price of raw nickel and its corrosion-resistant properties, which enhance durability in demanding environments. Copper mesh offers lower upfront costs and is widely available, benefiting from a well-established supply chain and broader industrial use. For applications requiring long-term performance and resistance to oxidation, investing in nickel mesh may be more economical despite its initial premium.

Choosing the Right Mesh: Nickel or Copper?

Nickel mesh offers superior corrosion resistance and durability compared to copper mesh, making it ideal for harsh chemical environments and long-term applications. Copper mesh provides excellent electrical conductivity and cost-effectiveness but may tarnish or oxidize faster, reducing its lifespan in moist or acidic conditions. Selecting between nickel and copper mesh depends on specific requirements such as environmental exposure, conductivity needs, and budget constraints.

Nickel Mesh vs Copper Mesh Infographic

materialdif.com

materialdif.com