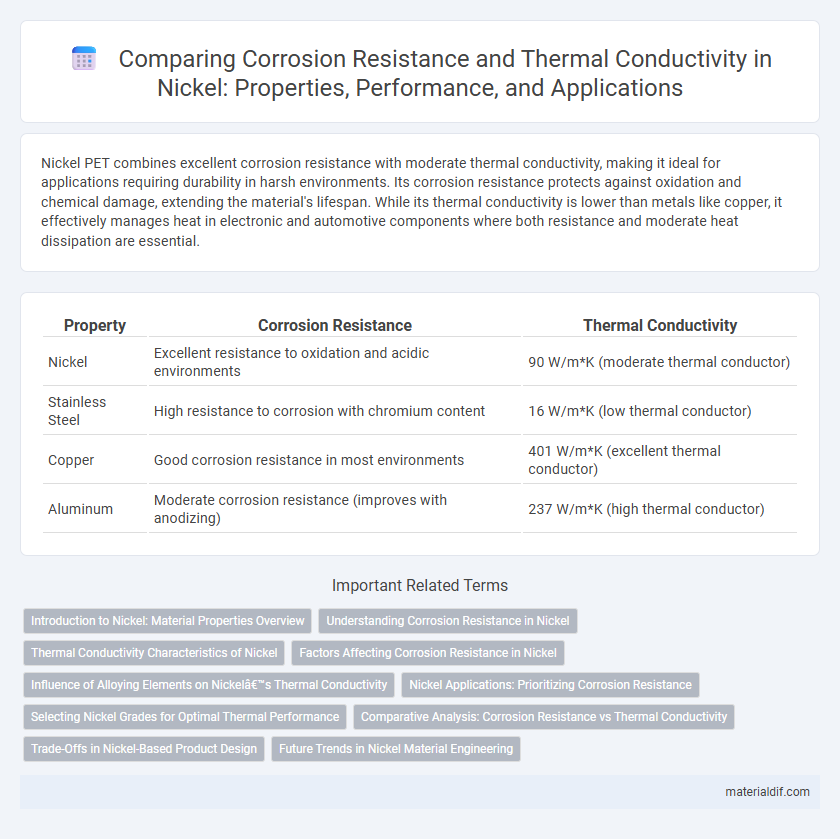

Nickel PET combines excellent corrosion resistance with moderate thermal conductivity, making it ideal for applications requiring durability in harsh environments. Its corrosion resistance protects against oxidation and chemical damage, extending the material's lifespan. While its thermal conductivity is lower than metals like copper, it effectively manages heat in electronic and automotive components where both resistance and moderate heat dissipation are essential.

Table of Comparison

| Property | Corrosion Resistance | Thermal Conductivity |

|---|---|---|

| Nickel | Excellent resistance to oxidation and acidic environments | 90 W/m*K (moderate thermal conductor) |

| Stainless Steel | High resistance to corrosion with chromium content | 16 W/m*K (low thermal conductor) |

| Copper | Good corrosion resistance in most environments | 401 W/m*K (excellent thermal conductor) |

| Aluminum | Moderate corrosion resistance (improves with anodizing) | 237 W/m*K (high thermal conductor) |

Introduction to Nickel: Material Properties Overview

Nickel exhibits exceptional corrosion resistance due to the formation of a stable oxide layer that protects against oxidation and chemical attacks, making it ideal for harsh environments. Its thermal conductivity, while lower than metals like copper, remains sufficient for applications requiring moderate heat transfer combined with durability. These combined properties position nickel as a versatile material in industries such as aerospace, chemical processing, and electronics.

Understanding Corrosion Resistance in Nickel

Nickel exhibits excellent corrosion resistance due to its ability to form a stable, adherent oxide layer that protects the metal from corrosive environments. This passive oxide film significantly reduces the rate of metal oxidation and degradation, making nickel ideal for chemical processing and marine applications. Understanding nickel's corrosion mechanisms is crucial for optimizing its use in environments requiring both durability and resistance to thermal stresses.

Thermal Conductivity Characteristics of Nickel

Nickel exhibits a moderate thermal conductivity of approximately 90 W/m*K at room temperature, enabling efficient heat transfer in high-temperature applications. Its thermal conductivity decreases gradually as temperature increases, maintaining stable performance in environments exceeding 500degC. This characteristic combined with its excellent corrosion resistance makes nickel ideal for heat exchangers and chemical processing equipment.

Factors Affecting Corrosion Resistance in Nickel

Corrosion resistance in nickel is significantly influenced by its alloy composition, surface treatment, and environmental conditions such as pH and temperature. High chromium and molybdenum content enhance the formation of a stable passive oxide layer, improving resistance to oxidation and chemical attack. Thermal conductivity in nickel alloys is generally lower than in pure metals, affecting heat dissipation and potentially accelerating localized corrosion under thermal stress.

Influence of Alloying Elements on Nickel’s Thermal Conductivity

Alloying elements such as chromium, iron, and molybdenum significantly reduce nickel's thermal conductivity while enhancing its corrosion resistance, creating a critical trade-off in high-performance applications. The addition of chromium improves oxidation resistance and passivation but decreases thermal conductivity by disrupting the metal's crystal lattice. Optimizing the balance between thermal conductivity and corrosion resistance involves careful control of alloy composition to meet specific engineering requirements in sectors like aerospace and chemical processing.

Nickel Applications: Prioritizing Corrosion Resistance

Nickel's superior corrosion resistance makes it a preferred material for applications in harsh environments such as chemical processing, marine equipment, and battery production, where exposure to corrosive agents is frequent. While thermal conductivity is essential in heat exchangers and electronic devices, nickel alloys are often selected to optimize durability rather than heat transfer. Prioritizing corrosion resistance in nickel-based materials ensures prolonged service life and reliability in industrial uses exposed to extreme conditions.

Selecting Nickel Grades for Optimal Thermal Performance

Selecting nickel grades for optimal thermal performance involves balancing corrosion resistance with thermal conductivity to meet specific application requirements. High-purity nickel grades exhibit superior thermal conductivity, making them ideal for heat exchangers and electronic components, while alloyed nickel variants provide enhanced corrosion resistance for harsh chemical environments but typically have lower thermal conductivity. Careful evaluation of nickel's grade composition and the operating conditions ensures maximized efficiency in thermal management systems without compromising durability.

Comparative Analysis: Corrosion Resistance vs Thermal Conductivity

Nickel exhibits superior corrosion resistance compared to many other metals, making it ideal for harsh chemical environments and marine applications. However, its thermal conductivity is relatively moderate, lower than metals like copper and aluminum, which limits its efficiency in heat transfer applications. The comparative analysis reveals that while nickel excels in durability against corrosion, it compromises on thermal conductivity, necessitating trade-offs in materials engineering depending on the application requirements.

Trade-Offs in Nickel-Based Product Design

Nickel's superior corrosion resistance stems from its stable oxide layer, which protects against aggressive environments but can limit its thermal conductivity compared to other metals like copper. In nickel-based product design, balancing the trade-off between maintaining corrosion resistance and enhancing thermal conductivity is crucial for applications such as heat exchangers and chemical reactors. Engineers optimize alloy composition and microstructure to achieve an ideal compromise, ensuring durability without sacrificing essential heat transfer efficiency.

Future Trends in Nickel Material Engineering

Future trends in nickel material engineering emphasize enhancing corrosion resistance without significantly compromising thermal conductivity, driven by advancements in alloy composition and surface treatments. Innovations like nanostructured nickel alloys and protective coatings are engineered to balance durability in aggressive environments with efficient heat dissipation. Research into high-entropy alloys and additive manufacturing techniques promises to tailor nickel's microstructure for optimized performance in aerospace, energy, and electronics industries.

Corrosion Resistance vs Thermal Conductivity Infographic

materialdif.com

materialdif.com