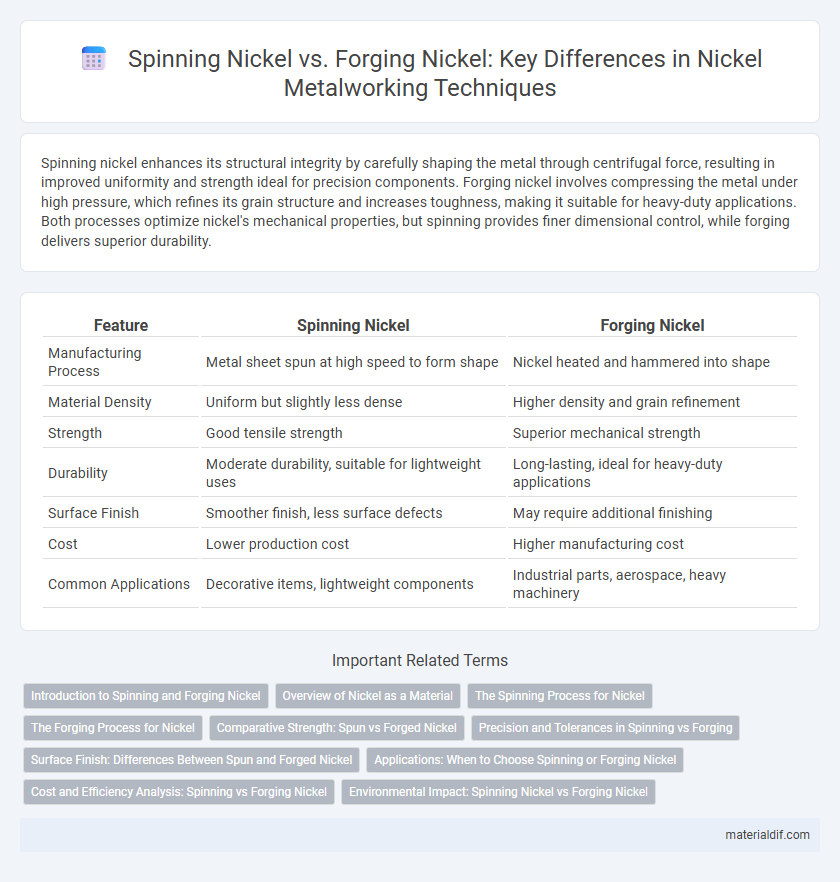

Spinning nickel enhances its structural integrity by carefully shaping the metal through centrifugal force, resulting in improved uniformity and strength ideal for precision components. Forging nickel involves compressing the metal under high pressure, which refines its grain structure and increases toughness, making it suitable for heavy-duty applications. Both processes optimize nickel's mechanical properties, but spinning provides finer dimensional control, while forging delivers superior durability.

Table of Comparison

| Feature | Spinning Nickel | Forging Nickel |

|---|---|---|

| Manufacturing Process | Metal sheet spun at high speed to form shape | Nickel heated and hammered into shape |

| Material Density | Uniform but slightly less dense | Higher density and grain refinement |

| Strength | Good tensile strength | Superior mechanical strength |

| Durability | Moderate durability, suitable for lightweight uses | Long-lasting, ideal for heavy-duty applications |

| Surface Finish | Smoother finish, less surface defects | May require additional finishing |

| Cost | Lower production cost | Higher manufacturing cost |

| Common Applications | Decorative items, lightweight components | Industrial parts, aerospace, heavy machinery |

Introduction to Spinning and Forging Nickel

Spinning nickel involves shaping the metal by rotating it on a lathe while applying pressure, resulting in smooth, symmetrical forms ideal for complex, curved components. Forging nickel uses compressive forces to deform the metal, enhancing its strength and grain structure, suitable for high-stress applications where durability is essential. Both processes optimize nickel's mechanical properties for specific industrial uses, with spinning excelling in precision and forging in toughness.

Overview of Nickel as a Material

Nickel, a corrosion-resistant and durable metal, exhibits distinct properties in spinning and forging processes that impact its mechanical strength and surface finish. Spinning nickel forms smooth, seamless components ideal for aerospace and industrial applications due to enhanced ductility and consistent grain flow. Forging nickel produces superior structural integrity with increased toughness and fatigue resistance, making it suitable for high-stress parts in automotive and energy sectors.

The Spinning Process for Nickel

The spinning process for nickel involves shaping a nickel disc or tube on a lathe by applying pressure with a roller or tool, allowing precise control over thickness and form. This technique enhances the metal's mechanical properties, such as strength and grain structure, resulting in components ideal for aerospace and industrial applications. Spinning nickel improves surface finish and reduces material waste compared to traditional forging methods.

The Forging Process for Nickel

The forging process for nickel involves shaping the metal under high pressure, enhancing its grain structure and mechanical properties such as strength and ductility. This method heats the nickel to a specific temperature range, typically between 1200degF and 2200degF, allowing it to be formed without cracking or distortion. Forged nickel components are commonly used in aerospace, chemical processing, and power generation industries due to their superior durability and resistance to corrosion compared to spun nickel products.

Comparative Strength: Spun vs Forged Nickel

Spun nickel exhibits uniform grain flow and improved structural integrity, resulting in enhanced tensile strength compared to forged nickel. Forged nickel typically offers superior impact resistance and fatigue strength due to its directional grain alignment from the forging process. The choice between spinning and forging nickel depends on the specific strength requirements and performance characteristics needed for the application.

Precision and Tolerances in Spinning vs Forging

Spinning nickel offers superior precision and tighter tolerances compared to forging due to its controlled rotational forming process, which allows for uniform material distribution and minimal deformation. Forging nickel involves compressive forces that can introduce inconsistencies and wider tolerance ranges but provides enhanced strength through grain refinement. Precision components requiring exact dimensions commonly utilize spinning nickel to achieve high accuracy and smooth surface finishes.

Surface Finish: Differences Between Spun and Forged Nickel

Spinning nickel generates a smoother, more uniform surface finish due to the metal being plastically deformed around a mandrel under high pressure, minimizing surface imperfections. Forging nickel often results in a textured or slightly rougher surface as the metal is compressed and shaped using dies, which can leave die marks or grain flow variations. These surface finish differences impact post-processing needs, with spun nickel typically requiring less machining and polishing.

Applications: When to Choose Spinning or Forging Nickel

Spinning nickel is ideal for creating seamless, hollow components such as fuel tanks, decorative items, and heat exchangers due to its excellent surface finish and high strength-to-weight ratio. Forging nickel excels in applications requiring superior structural integrity and impact resistance, including aerospace turbine blades, engine components, and high-stress mechanical parts. Choosing between spinning and forging nickel depends on the specific performance requirements and geometrical complexity of the final product.

Cost and Efficiency Analysis: Spinning vs Forging Nickel

Spinning nickel offers cost advantages through reduced material waste and lower energy consumption compared to forging, which often requires higher temperatures and longer processing times. Forging nickel provides superior mechanical properties and structural integrity but involves higher labor and equipment expenses. Efficiency in spinning favors rapid production of thin-walled components, while forging excels in creating complex, high-strength parts despite elevated operational costs.

Environmental Impact: Spinning Nickel vs Forging Nickel

Spinning nickel typically generates less industrial waste and consumes less energy compared to forging nickel, contributing to a smaller carbon footprint in manufacturing processes. Forging nickel, while offering enhanced mechanical properties, often requires higher temperatures and more extensive machining, leading to increased energy consumption and potential emissions. Choosing spinning over forging nickel can significantly reduce environmental impact by minimizing resource use and lowering greenhouse gas emissions.

Spinning nickel vs Forging nickel Infographic

materialdif.com

materialdif.com