Nickel-coated copper offers enhanced corrosion resistance and improved durability compared to bare copper, making it ideal for applications requiring long-term reliability. The nickel layer acts as a protective barrier, preventing oxidation and maintaining electrical conductivity over time. Bare copper, while highly conductive and cost-effective, is more susceptible to tarnishing and environmental damage without protective coatings.

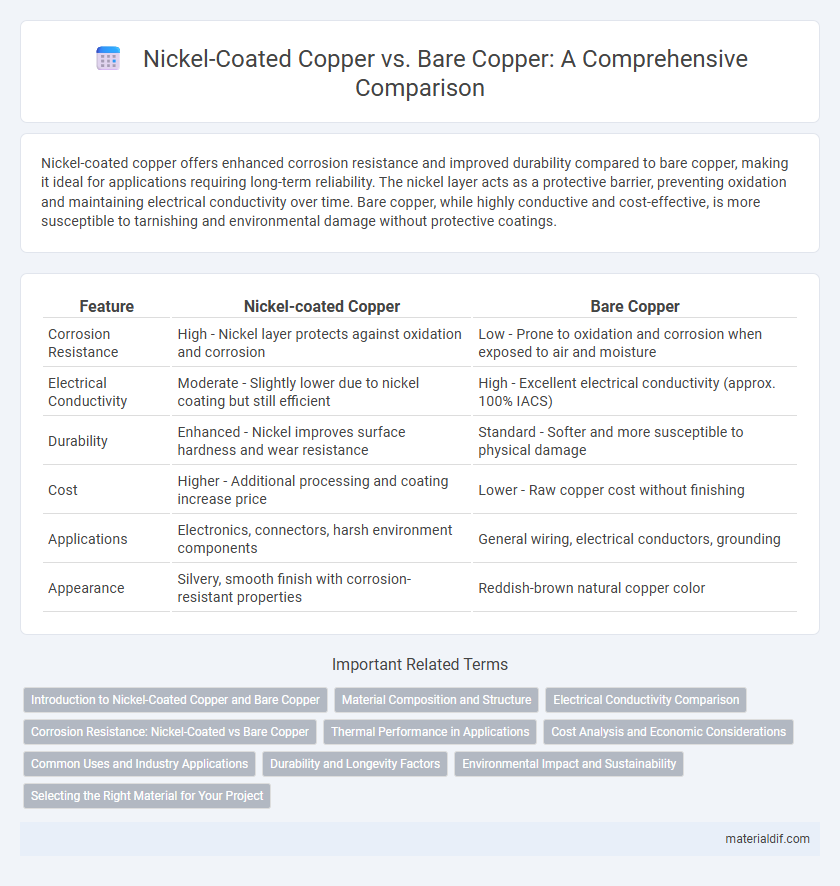

Table of Comparison

| Feature | Nickel-coated Copper | Bare Copper |

|---|---|---|

| Corrosion Resistance | High - Nickel layer protects against oxidation and corrosion | Low - Prone to oxidation and corrosion when exposed to air and moisture |

| Electrical Conductivity | Moderate - Slightly lower due to nickel coating but still efficient | High - Excellent electrical conductivity (approx. 100% IACS) |

| Durability | Enhanced - Nickel improves surface hardness and wear resistance | Standard - Softer and more susceptible to physical damage |

| Cost | Higher - Additional processing and coating increase price | Lower - Raw copper cost without finishing |

| Applications | Electronics, connectors, harsh environment components | General wiring, electrical conductors, grounding |

| Appearance | Silvery, smooth finish with corrosion-resistant properties | Reddish-brown natural copper color |

Introduction to Nickel-Coated Copper and Bare Copper

Nickel-coated copper combines the excellent electrical conductivity of copper with a durable nickel layer that enhances corrosion resistance and wear properties. Bare copper offers superior electrical and thermal conductivity but lacks protective coating, making it more susceptible to oxidation and environmental degradation. The choice between nickel-coated and bare copper depends on application requirements, balancing conductivity, durability, and exposure conditions.

Material Composition and Structure

Nickel-coated copper consists of a core copper layer electroplated with a thin nickel layer, enhancing corrosion resistance and wear durability compared to bare copper's uniform composition. The nickel coating acts as a protective barrier, preventing oxidation and improving conductivity stability in harsh environments. This layered structure maintains copper's excellent electrical conductivity while providing superior mechanical strength and chemical resistance.

Electrical Conductivity Comparison

Nickel-coated copper offers enhanced corrosion resistance while maintaining electrical conductivity close to that of bare copper, typically around 85-95% IACS (International Annealed Copper Standard). Bare copper, with its superior conductivity at 100% IACS, remains the preferred choice for applications demanding maximum electrical efficiency. The trade-off between corrosion protection and conductivity often guides the selection between nickel-coated and bare copper in electrical and electronic components.

Corrosion Resistance: Nickel-Coated vs Bare Copper

Nickel-coated copper exhibits superior corrosion resistance compared to bare copper, especially in harsh environments where exposure to moisture, chemicals, or saltwater accelerates oxidation. The nickel layer forms a protective barrier that prevents copper from tarnishing and developing patina, significantly extending the lifespan of electrical connectors and components. Bare copper, while highly conductive, is prone to corrosion and surface degradation, which can lead to increased electrical resistance and connection failures over time.

Thermal Performance in Applications

Nickel-coated copper demonstrates enhanced thermal performance compared to bare copper due to its improved oxidation resistance and long-term stability at high temperatures. The nickel layer acts as a protective barrier, reducing corrosion and maintaining thermal conductivity in demanding environments such as electronics and heat exchangers. While bare copper exhibits superior initial thermal conductivity, its susceptibility to oxidation significantly diminishes performance over time without protective coatings.

Cost Analysis and Economic Considerations

Nickel-coated copper typically incurs higher initial costs than bare copper due to the additional coating process, yet it offers superior corrosion resistance and longer lifespan, reducing maintenance expenses in the long term. Bare copper remains cost-effective for applications where environmental exposure is minimal and conductivity is prioritized, but may incur higher replacement costs over time due to oxidation. Economic considerations must balance upfront investment against durability and performance benefits, influencing total cost of ownership in industrial and electrical applications.

Common Uses and Industry Applications

Nickel-coated copper offers enhanced corrosion resistance and electrical conductivity, making it ideal for connectors, printed circuit boards, and telecommunications equipment where durability and performance are critical. Bare copper remains widely used in electrical wiring, plumbing, and heat exchangers due to its excellent conductivity and cost-effectiveness. Industries such as automotive, electronics, and aerospace rely on nickel-coated copper for components exposed to harsh environments, while bare copper is preferred in building infrastructure and electrical transmission.

Durability and Longevity Factors

Nickel-coated copper offers superior corrosion resistance compared to bare copper, significantly enhancing durability in harsh environments. The nickel layer acts as a protective barrier against oxidation and wear, extending the lifespan of copper components in electrical and industrial applications. Bare copper, while highly conductive, is more susceptible to tarnishing and degradation over time, resulting in reduced longevity.

Environmental Impact and Sustainability

Nickel-coated copper offers improved corrosion resistance compared to bare copper, extending product lifespan and reducing waste in electronic applications. The environmental impact of nickel coating involves additional resource extraction and energy use but can lead to lower overall lifecycle emissions due to enhanced durability. Bare copper requires less processing but may result in higher replacement rates, increasing long-term environmental footprint from material consumption and disposal.

Selecting the Right Material for Your Project

Nickel-coated copper provides superior corrosion resistance and enhanced electrical conductivity compared to bare copper, making it ideal for high-performance electronic applications and harsh environments. Bare copper offers excellent thermal and electrical conductivity at a lower cost but is prone to oxidation and wear over time. Selecting the right material depends on the specific requirements of your project, including environmental exposure, budget constraints, and durability needs.

Nickel-coated Copper vs Bare Copper Infographic

materialdif.com

materialdif.com