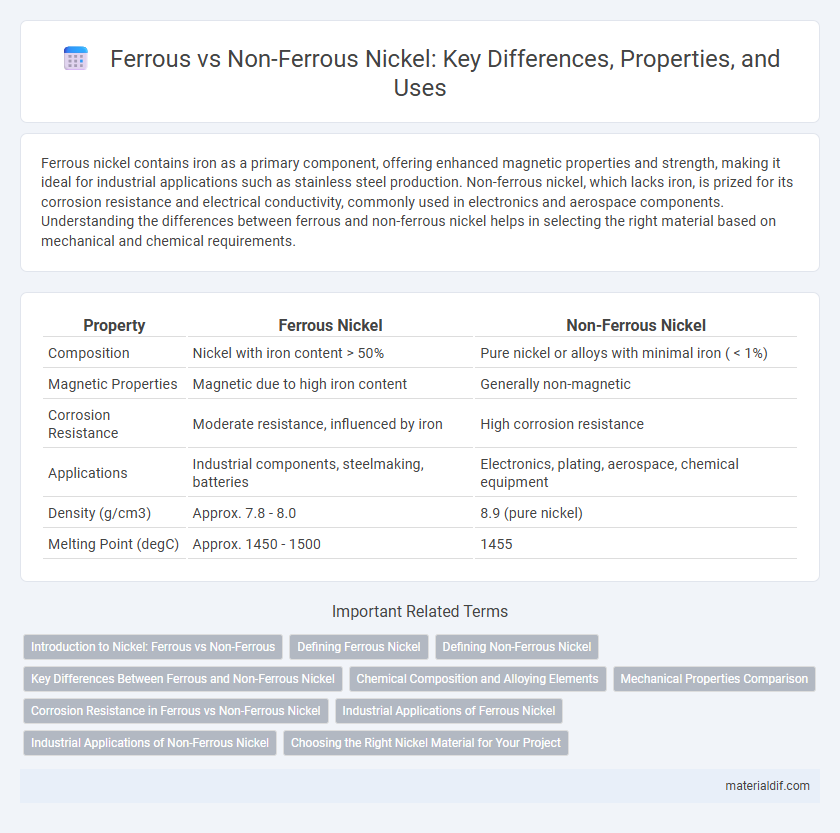

Ferrous nickel contains iron as a primary component, offering enhanced magnetic properties and strength, making it ideal for industrial applications such as stainless steel production. Non-ferrous nickel, which lacks iron, is prized for its corrosion resistance and electrical conductivity, commonly used in electronics and aerospace components. Understanding the differences between ferrous and non-ferrous nickel helps in selecting the right material based on mechanical and chemical requirements.

Table of Comparison

| Property | Ferrous Nickel | Non-Ferrous Nickel |

|---|---|---|

| Composition | Nickel with iron content > 50% | Pure nickel or alloys with minimal iron ( < 1%) |

| Magnetic Properties | Magnetic due to high iron content | Generally non-magnetic |

| Corrosion Resistance | Moderate resistance, influenced by iron | High corrosion resistance |

| Applications | Industrial components, steelmaking, batteries | Electronics, plating, aerospace, chemical equipment |

| Density (g/cm3) | Approx. 7.8 - 8.0 | 8.9 (pure nickel) |

| Melting Point (degC) | Approx. 1450 - 1500 | 1455 |

Introduction to Nickel: Ferrous vs Non-Ferrous

Ferrous nickel refers to nickel alloys that contain significant amounts of iron, commonly used in stainless steel production for enhanced corrosion resistance and strength. Non-ferrous nickel includes pure nickel and nickel alloys without iron, valued for excellent thermal conductivity, magnetic properties, and resistance to oxidation. Understanding the distinction between ferrous and non-ferrous nickel is critical for selecting materials in industries such as aerospace, automotive, and electronics.

Defining Ferrous Nickel

Ferrous nickel is a type of nickel alloy containing a significant proportion of iron, typically ranging from 30% to 40%, which enhances its magnetic properties and mechanical strength. This composition distinguishes ferrous nickel from non-ferrous nickel, which has minimal or no iron content and exhibits different corrosion resistance and conductivity characteristics. Ferrous nickel is widely used in applications requiring durability and magnetic performance, such as in electrical components and alloy steel production.

Defining Non-Ferrous Nickel

Non-ferrous nickel refers to nickel materials that do not contain significant amounts of iron, distinguishing them from ferrous nickel alloys primarily composed of iron and nickel. This category includes pure nickel and nickel-based alloys used in applications requiring corrosion resistance, high conductivity, and non-magnetic properties. Non-ferrous nickel is essential in industries such as aerospace, electronics, and chemical processing where iron contamination must be minimized.

Key Differences Between Ferrous and Non-Ferrous Nickel

Ferrous nickel contains iron, which enhances magnetic properties and strength, making it ideal for stainless steel production and industrial alloys. Non-ferrous nickel lacks iron, offering greater corrosion resistance and electrical conductivity, crucial in battery manufacturing and electronics. The key differences lie in their composition, magnetism, corrosion resistance, and typical applications across various industries.

Chemical Composition and Alloying Elements

Ferrous nickel alloys primarily contain iron as the main alloying element, with nickel typically ranging between 30% to 60%, enhancing strength and magnetic properties in applications like stainless steel production. Non-ferrous nickel alloys lack significant iron content and instead combine nickel with elements such as copper, chromium, and molybdenum to improve corrosion resistance, heat tolerance, and mechanical performance in aerospace and chemical industries. The chemical composition of ferrous nickel alloys is characterized by higher iron content, while non-ferrous nickel alloys emphasize diverse alloying elements tailored for specialized environments.

Mechanical Properties Comparison

Ferrous nickel alloys typically exhibit higher tensile strength and improved resistance to wear and corrosion due to their iron content, making them ideal for heavy-duty applications. Non-ferrous nickel alloys, while generally offering superior corrosion resistance and thermal stability, tend to have lower density and enhanced ductility, benefiting lightweight and high-precision engineering uses. The choice between ferrous and non-ferrous nickel depends on the required balance of mechanical strength, corrosion resistance, and weight for specific industrial applications.

Corrosion Resistance in Ferrous vs Non-Ferrous Nickel

Ferrous nickel alloys contain iron, enhancing their mechanical strength and corrosion resistance in harsh environments such as marine and chemical industries. Non-ferrous nickel, often used in pure or alloyed forms without iron, offers superior resistance to oxidation and acidic conditions but typically lacks the structural durability found in ferrous variants. Comparing corrosion resistance, ferrous nickel excels in high-stress applications with moderate corrosive exposure, while non-ferrous nickel is preferred for environments demanding exceptional chemical resistance and minimal oxidation.

Industrial Applications of Ferrous Nickel

Ferrous nickel, an alloy primarily composed of iron and nickel, is extensively used in industrial applications requiring high strength, corrosion resistance, and heat tolerance, such as in stainless steel manufacturing and aerospace components. Its ability to enhance durability and maintain structural integrity under extreme conditions makes it crucial in chemical processing equipment, power plants, and automotive parts. Non-ferrous nickel, lacking iron content, is more often utilized in coinage and electronics due to its excellent electrical conductivity and corrosion resistance.

Industrial Applications of Non-Ferrous Nickel

Non-ferrous nickel, characterized by its resistance to corrosion and excellent thermal stability, is extensively utilized in aerospace, chemical processing, and electronics industries. Its ability to maintain strength and performance at high temperatures makes it indispensable in turbine blades, heat exchangers, and battery components. Unlike ferrous nickel alloys, non-ferrous nickel does not contain significant iron content, enhancing its suitability for specialized industrial applications requiring superior corrosion resistance and conductivity.

Choosing the Right Nickel Material for Your Project

Ferrous nickel alloys, containing iron, offer enhanced strength, corrosion resistance, and magnetic properties ideal for heavy-duty industrial applications like turbines and chemical processing equipment. Non-ferrous nickel materials, which exclude iron, provide superior ductility, electrical conductivity, and resistance to oxidation, making them suitable for electronics, plating, and aerospace components. Selecting the right nickel material depends on project requirements such as mechanical strength, corrosion resistance, and thermal stability to ensure optimal performance and longevity.

Ferrous nickel vs non-ferrous nickel Infographic

materialdif.com

materialdif.com