Melting nickel involves heating the metal above its melting point to form a molten state, resulting in a dense and homogeneous structure upon cooling. Sintering nickel, however, compacts nickel powder at temperatures below its melting point, creating a solid mass through particle bonding without complete liquefaction. The choice between melting and sintering nickel impacts the material's microstructure, mechanical properties, and suitability for specific industrial applications.

Table of Comparison

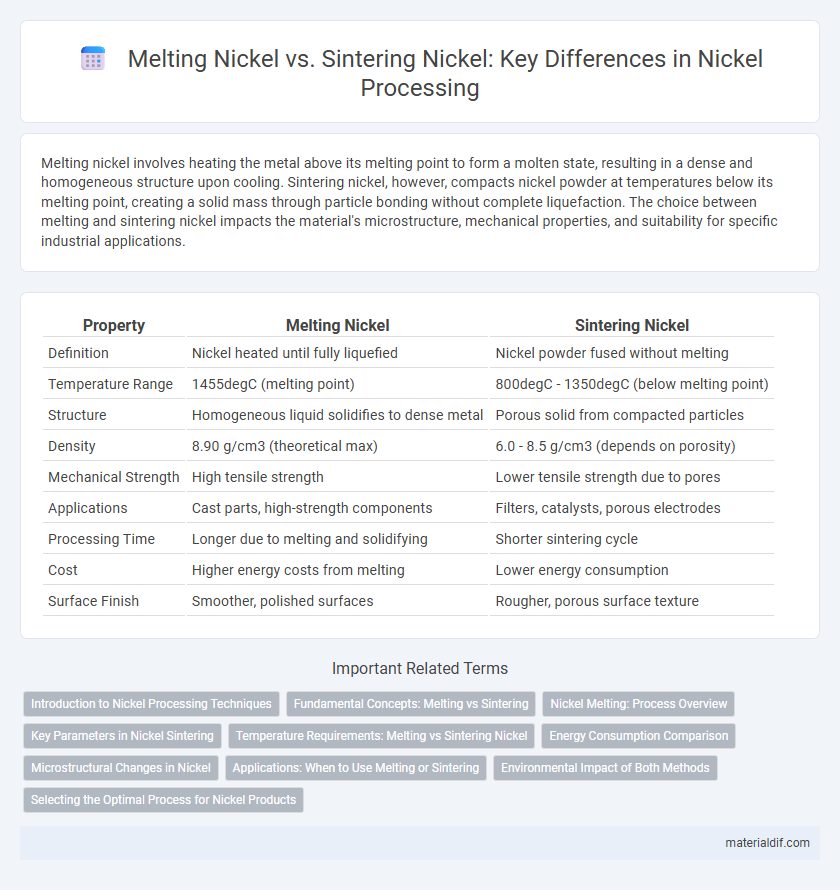

| Property | Melting Nickel | Sintering Nickel |

|---|---|---|

| Definition | Nickel heated until fully liquefied | Nickel powder fused without melting |

| Temperature Range | 1455degC (melting point) | 800degC - 1350degC (below melting point) |

| Structure | Homogeneous liquid solidifies to dense metal | Porous solid from compacted particles |

| Density | 8.90 g/cm3 (theoretical max) | 6.0 - 8.5 g/cm3 (depends on porosity) |

| Mechanical Strength | High tensile strength | Lower tensile strength due to pores |

| Applications | Cast parts, high-strength components | Filters, catalysts, porous electrodes |

| Processing Time | Longer due to melting and solidifying | Shorter sintering cycle |

| Cost | Higher energy costs from melting | Lower energy consumption |

| Surface Finish | Smoother, polished surfaces | Rougher, porous surface texture |

Introduction to Nickel Processing Techniques

Nickel processing techniques such as melting and sintering significantly influence the metal's properties and applications in various industries. Melting involves heating nickel above its melting point of 1455degC to produce homogeneous alloys or castings with uniform microstructures. Sintering, conversely, compacts and bonds nickel powders below their melting point, enabling the production of complex shapes with fine microstructural control and enhanced mechanical properties.

Fundamental Concepts: Melting vs Sintering

Melting nickel involves heating the metal above its melting point of 1455degC to transform it into a liquid state, enabling casting and shaping processes. Sintering nickel, by contrast, heats powdered nickel below its melting point, causing particles to bond through diffusion without reaching a liquid phase, preserving porosity and structural integrity. Understanding the fundamental difference between melting and sintering nickel is crucial for selecting appropriate manufacturing methods in industries such as aerospace and electronics.

Nickel Melting: Process Overview

Nickel melting involves heating raw nickel ore or scrap metal to temperatures above its melting point of 1455degC, creating a molten state suitable for casting or alloy production. This process ensures high purity and homogeneity by removing impurities and controlling oxidation through flux addition and atmosphere control. In contrast, sintering nickel involves compacting and heating powdered nickel below its melting point to form solid masses without liquefying the metal.

Key Parameters in Nickel Sintering

Nickel sintering involves key parameters such as temperature, atmosphere, and pressure, critically impacting the density, grain growth, and mechanical strength of the final product. Unlike melting nickel, which requires temperatures above 1455degC to liquefy the metal, sintering typically occurs below the melting point, usually between 1200degC and 1350degC, allowing for controlled diffusion and bonding of nickel particles. Optimizing the sintering atmosphere, often using hydrogen or vacuum, prevents oxidation and enhances the quality and conductivity of sintered nickel parts.

Temperature Requirements: Melting vs Sintering Nickel

Melting nickel requires reaching its melting point at approximately 1455degC (2651degF), whereas sintering nickel occurs at lower temperatures, typically between 800degC and 1300degC, just below its melting point. Sintering facilitates particle bonding without complete liquefaction, preserving structural integrity and minimizing oxidation risks. Melting, on the other hand, involves full liquefaction, enabling casting but demanding higher energy consumption and controlled cooling processes.

Energy Consumption Comparison

Melting nickel requires significantly higher energy input due to its melting point of 1455degC, demanding intense heat to transition from solid to liquid. In contrast, sintering nickel, a process involving heating powdered nickel below its melting point to bond particles, consumes less energy by avoiding full liquefaction. Energy consumption during sintering varies but generally remains lower than melting, making sintering a more cost-effective and energy-efficient method in nickel processing.

Microstructural Changes in Nickel

Melting nickel results in a homogeneous microstructure due to the complete phase transition from solid to liquid and subsequent solidification, typically forming large, equiaxed grains with minimal defects. Sintering nickel, however, involves solid-state diffusion that promotes neck growth and densification while retaining finer, more irregular grain boundaries and porosity between particles. These microstructural distinctions impact mechanical properties, with melted nickel exhibiting improved ductility and sintered nickel maintaining higher surface area and potential for grain boundary strengthening.

Applications: When to Use Melting or Sintering

Melting nickel is ideal for applications requiring high structural integrity and dense, homogeneous components, such as aerospace turbine blades and corrosion-resistant industrial parts. Sintering nickel suits manufacturing of complex shapes with controlled porosity, commonly used in electronics, filters, and battery electrodes. Choosing between melting and sintering depends on the required mechanical strength, microstructure, and application-specific performance criteria.

Environmental Impact of Both Methods

Melting nickel typically requires high energy consumption and emits substantial greenhouse gases due to the intense heat needed, whereas sintering nickel operates at lower temperatures, reducing overall energy usage and carbon emissions. Sintering processes generate fewer hazardous byproducts, leading to less air and water pollution compared to the melting method, which can release toxic metal fumes and slag. Choosing sintering over melting contributes to a smaller environmental footprint by minimizing resource depletion and reducing ecological harm from nickel production.

Selecting the Optimal Process for Nickel Products

Selecting the optimal process for nickel products involves evaluating melting nickel, which provides uniform alloy composition and high structural integrity, against sintering nickel, favored for complex shapes and enhanced porosity control. Melting techniques like vacuum induction melting achieve purity levels above 99.9%, ideal for high-performance aerospace components, while sintering processes excel in producing porous nickel parts for battery electrodes and fuel cells. Understanding the end-use requirements such as mechanical strength, electrical conductivity, and dimensional precision guides the choice between melting and sintering nickel to maximize product performance and cost-efficiency.

Melting Nickel vs Sintering Nickel Infographic

materialdif.com

materialdif.com