Matte nickel offers a subtle, muted finish ideal for modern and minimalist designs, providing a soft and understated look. Bright nickel features a shiny, reflective surface that enhances visual appeal with a polished and vibrant appearance. Choosing between matte and bright nickel depends on the desired aesthetic and the surrounding decor style.

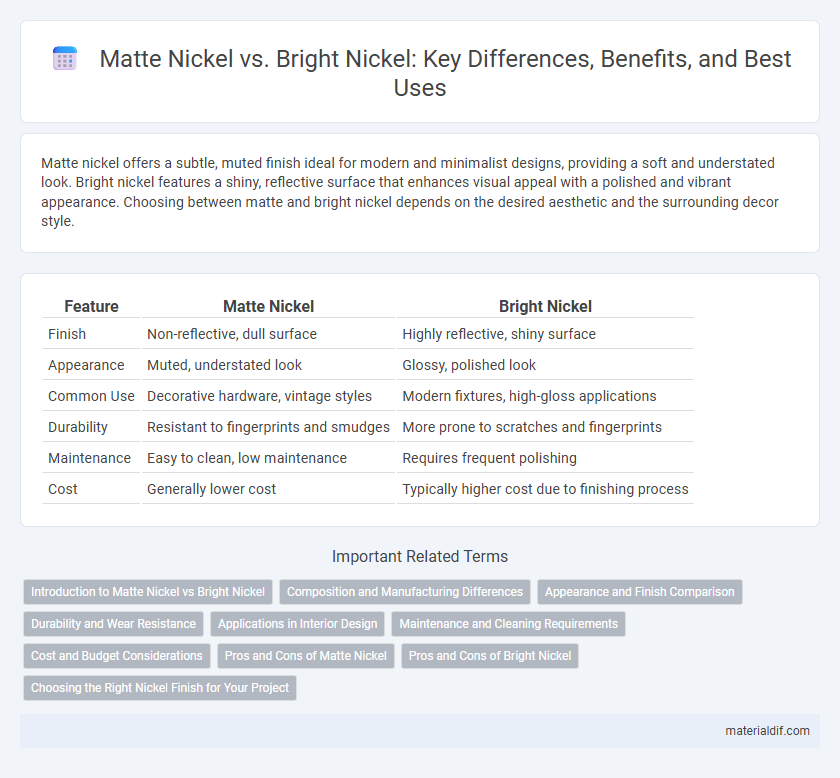

Table of Comparison

| Feature | Matte Nickel | Bright Nickel |

|---|---|---|

| Finish | Non-reflective, dull surface | Highly reflective, shiny surface |

| Appearance | Muted, understated look | Glossy, polished look |

| Common Use | Decorative hardware, vintage styles | Modern fixtures, high-gloss applications |

| Durability | Resistant to fingerprints and smudges | More prone to scratches and fingerprints |

| Maintenance | Easy to clean, low maintenance | Requires frequent polishing |

| Cost | Generally lower cost | Typically higher cost due to finishing process |

Introduction to Matte Nickel vs Bright Nickel

Matte nickel and bright nickel are two distinct types of nickel plating used in various industrial and decorative applications. Matte nickel has a dull, non-reflective finish achieved through specific chemical treatments, offering excellent corrosion resistance and a subtle aesthetic. Bright nickel, characterized by its highly reflective, shiny surface, is favored for decorative purposes and provides enhanced surface smoothness and durability.

Composition and Manufacturing Differences

Matte nickel typically contains a higher proportion of sulfur and carbon compounds, which contribute to its dull, non-reflective surface, while bright nickel is composed primarily of pure nickel with minor alloying elements to enhance its luster. Matte nickel is produced through electroplating processes that promote a coarse crystalline structure, resulting in a matte finish, whereas bright nickel undergoes electroplating or chemical plating techniques designed to create a smooth, polished surface. The key manufacturing difference lies in the plating bath additives and electrical parameters, which control the deposit morphology and determine the final appearance and corrosion resistance of each nickel type.

Appearance and Finish Comparison

Matte nickel features a dull, non-reflective surface with a soft, muted finish, ideal for contemporary designs seeking understated elegance. Bright nickel offers a shiny, highly reflective appearance with a polished finish that enhances brightness and highlights intricate details. The choice between matte and bright nickel finishes significantly impacts the visual appeal and style of metal fixtures and hardware.

Durability and Wear Resistance

Matte nickel offers superior durability and wear resistance compared to bright nickel due to its thicker and more uniform plating, which provides enhanced protection against corrosion and abrasion. Bright nickel, while aesthetically glossy, tends to be thinner and more prone to scratching and tarnishing under heavy use. Industries requiring long-lasting finishes, such as automotive and electronics, often prefer matte nickel for its robustness and extended lifespan.

Applications in Interior Design

Matte nickel features a subdued, non-reflective finish ideal for modern and minimalist interior design applications such as cabinet hardware, lighting fixtures, and faucets, creating a sophisticated, understated look. Bright nickel, with its highly reflective, shiny surface, is commonly used in traditional and transitional interior designs for decorative elements like door handles, trim, and bathroom accessories, enhancing elegance and visual contrast. Both finishes offer corrosion resistance and durability suitable for high-traffic areas, but the choice depends on the desired aesthetic and ambiance within the space.

Maintenance and Cleaning Requirements

Matte nickel requires less frequent cleaning due to its textured, non-reflective surface that hides fingerprints and smudges effectively. Bright nickel, characterized by its shiny, mirror-like finish, demands more regular maintenance to prevent tarnishing and visible water spots. Use mild soap and water for matte nickel, while bright nickel often needs gentle polishing with a specialized cleaner to maintain its luster.

Cost and Budget Considerations

Matte nickel plating generally costs less than bright nickel due to simpler processing and lower material requirements, making it suitable for budget-conscious projects. Bright nickel demands higher energy and more refined application techniques, increasing production expenses and overall pricing. Selecting matte nickel can optimize spending without compromising corrosion resistance in cost-sensitive applications.

Pros and Cons of Matte Nickel

Matte nickel offers a subdued, non-reflective finish that resists fingerprints and hides scratches better than bright nickel, making it ideal for high-traffic areas or surfaces prone to wear. Its muted appearance complements modern and industrial design aesthetics, while its durability provides good corrosion resistance, although it may show grime more easily than bright nickel. However, matte nickel can be harder to clean compared to the glossy, smooth surface of bright nickel, which reflects light and often appears more polished and luxurious.

Pros and Cons of Bright Nickel

Bright nickel offers superior corrosion resistance and an aesthetically pleasing shiny finish, making it ideal for decorative and protective coatings in automotive and household appliances. However, its higher production cost and more complex plating process compared to matte nickel can limit its use in cost-sensitive applications. Bright nickel's propensity to show fingerprints and scratches more easily also requires careful maintenance to preserve its appearance.

Choosing the Right Nickel Finish for Your Project

Matte nickel offers a subtle, low-gloss finish ideal for projects requiring a modern, understated look, while bright nickel provides a shiny, reflective surface that enhances traditional and decorative styles. Consider the environment and usage, as matte nickel resists fingerprints and scratches better, making it suitable for high-touch areas. Bright nickel's polished appeal suits accent pieces and fixtures where a striking, luminous effect is desired.

Matte nickel vs bright nickel Infographic

materialdif.com

materialdif.com