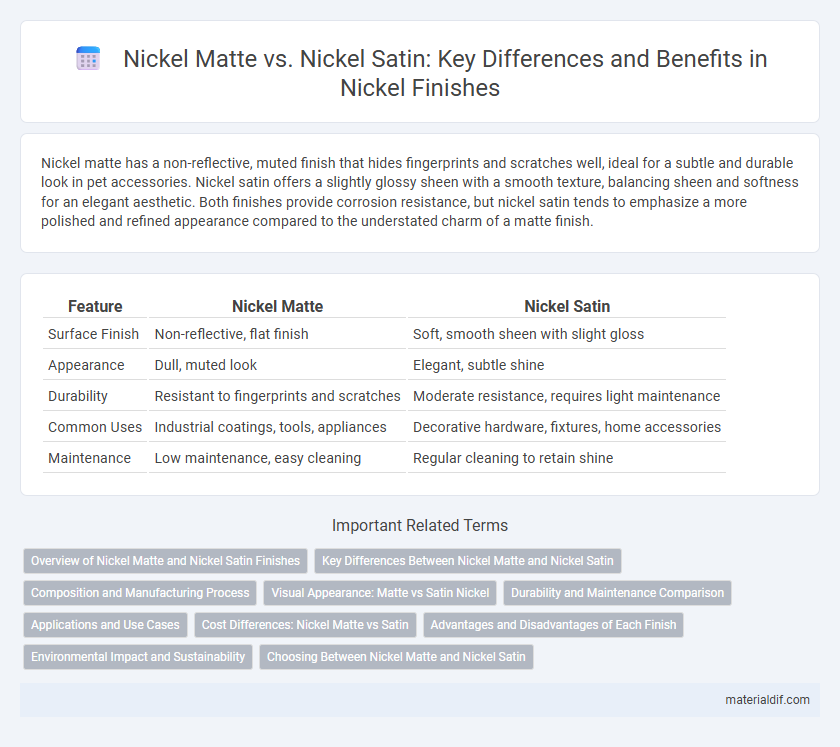

Nickel matte has a non-reflective, muted finish that hides fingerprints and scratches well, ideal for a subtle and durable look in pet accessories. Nickel satin offers a slightly glossy sheen with a smooth texture, balancing sheen and softness for an elegant aesthetic. Both finishes provide corrosion resistance, but nickel satin tends to emphasize a more polished and refined appearance compared to the understated charm of a matte finish.

Table of Comparison

| Feature | Nickel Matte | Nickel Satin |

|---|---|---|

| Surface Finish | Non-reflective, flat finish | Soft, smooth sheen with slight gloss |

| Appearance | Dull, muted look | Elegant, subtle shine |

| Durability | Resistant to fingerprints and scratches | Moderate resistance, requires light maintenance |

| Common Uses | Industrial coatings, tools, appliances | Decorative hardware, fixtures, home accessories |

| Maintenance | Low maintenance, easy cleaning | Regular cleaning to retain shine |

Overview of Nickel Matte and Nickel Satin Finishes

Nickel matte finishes exhibit a non-reflective, subtle texture that minimizes visible fingerprints and surface imperfections, providing a sleek and understated appearance ideal for modern design applications. Nickel satin finishes offer a smooth, low-luster sheen with slight reflectivity, combining durability with a soft glow that enhances the metal's natural warmth and richness. Both finishes are corrosion-resistant and suitable for decorative hardware, lighting fixtures, and kitchen accessories, with the matte finish emphasizing a more muted aesthetic while the satin finish delivers a classic, elegant look.

Key Differences Between Nickel Matte and Nickel Satin

Nickel matte features a flat, non-reflective finish that minimizes glare and fingerprints, making it ideal for a subdued, modern look. Nickel satin has a smooth, slightly glossy surface with a subtle sheen that balances durability and elegance, often preferred for high-traffic areas. The key differences lie in their visual texture and light reflectivity, with matte offering a more muted appearance and satin providing a soft, lustrous glow.

Composition and Manufacturing Process

Nickel matte is primarily composed of nickel sulfide and is produced through the hydrometallurgical refining of nickel ores, resulting in a high-purity intermediate used for further refining. Nickel satin, on the other hand, refers to a nickel coating or finish characterized by its smooth, matte surface texture, achieved through controlled electroplating or chemical deposition processes. The key distinction lies in nickel matte being a raw material with sulfide impurities, while nickel satin is a finished product focused on aesthetic and corrosion-resistant properties.

Visual Appearance: Matte vs Satin Nickel

Matte nickel features a non-reflective, muted finish that minimizes glare and conceals fingerprints, creating a smooth, understated appearance ideal for modern and industrial designs. Satin nickel offers a soft sheen with a subtle luster, combining slight reflectivity with a smooth texture that enhances elegance without the shine of polished metal. The visual distinction lies in matte nickel's flat, dull surface versus satin nickel's gently glowing finish, influencing aesthetic choices in hardware and decorative applications.

Durability and Maintenance Comparison

Nickel matte finishes provide superior durability against scratches and corrosion due to their textured surface, making them ideal for high-traffic areas. Nickel satin offers a smoother, more refined look but requires more frequent maintenance to prevent visible fingerprints and smudges. Both finishes resist tarnishing, but matte nickel demands less upkeep, enhancing long-term appearance and functionality.

Applications and Use Cases

Nickel matte is primarily used in industrial applications such as electroplating, chemical manufacturing, and as a feedstock for refining pure nickel due to its high nickel content and impurities suitable for metallurgical processes. Nickel satin, valued for its smooth, matte finish, is commonly employed in decorative and architectural applications, including household fixtures, automotive trim, and electronic device casings that require corrosion resistance and aesthetic appeal. Both forms offer corrosion resistance and durability, but nickel matte's chemical properties cater to heavy industry, while nickel satin focuses on visual and tactile surface qualities for consumer products.

Cost Differences: Nickel Matte vs Satin

Nickel matte finishes generally cost less than nickel satin due to simpler manufacturing processes and lower demand in premium applications. Satin nickel requires additional polishing steps, increasing labor and production expenses, which raise overall costs. The price difference between nickel matte and satin typically ranges from 10% to 25%, influenced by factors like brand and application scale.

Advantages and Disadvantages of Each Finish

Nickel matte finish offers superior scratch resistance and a subtle, understated appearance ideal for high-traffic areas, but it tends to show fingerprints and smudges more easily. Nickel satin finish provides a smooth, lustrous surface with excellent corrosion resistance, creating a modern look while being easier to clean, yet it may reveal scratches more prominently over time. Choosing between matte and satin nickel depends on balancing durability needs with aesthetic preferences for specific applications.

Environmental Impact and Sustainability

Nickel matte production generates higher energy consumption and emissions due to the sulfur dioxide released during smelting, posing significant environmental challenges. Nickel satin, often produced with more refined processes like electroplating, tends to have a lower carbon footprint and reduced waste output. Sustainable nickel sourcing increasingly emphasizes recycling and cleaner technologies to minimize ecological damage associated with both matte and satin finishes.

Choosing Between Nickel Matte and Nickel Satin

Nickel matte offers a subdued, non-reflective finish ideal for industrial and vintage aesthetics, while nickel satin provides a smooth, lightly lustrous surface perfect for modern and decorative applications. Choosing between nickel matte and nickel satin depends on desired durability, light reflection, and style preference, with matte excelling in hiding fingerprints and scratches and satin enhancing the metal's natural brightness. Consider environmental exposure and maintenance requirements, as satin finishes may require more frequent cleaning to maintain their shine compared to the low-maintenance matte finish.

Nickel matte vs nickel satin Infographic

materialdif.com

materialdif.com