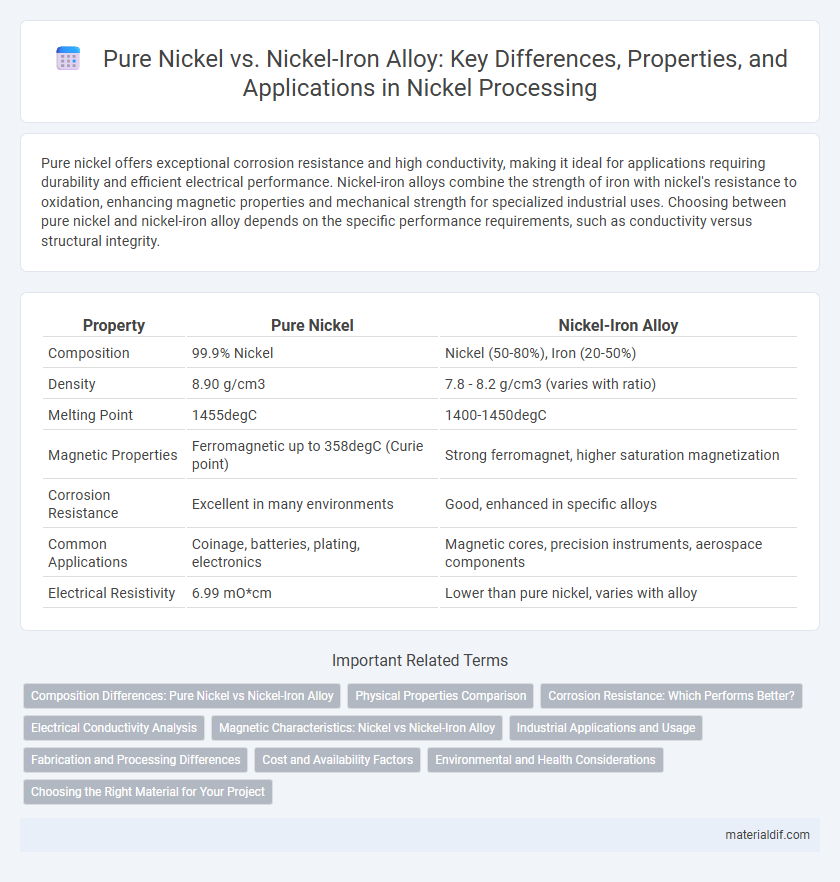

Pure nickel offers exceptional corrosion resistance and high conductivity, making it ideal for applications requiring durability and efficient electrical performance. Nickel-iron alloys combine the strength of iron with nickel's resistance to oxidation, enhancing magnetic properties and mechanical strength for specialized industrial uses. Choosing between pure nickel and nickel-iron alloy depends on the specific performance requirements, such as conductivity versus structural integrity.

Table of Comparison

| Property | Pure Nickel | Nickel-Iron Alloy |

|---|---|---|

| Composition | 99.9% Nickel | Nickel (50-80%), Iron (20-50%) |

| Density | 8.90 g/cm3 | 7.8 - 8.2 g/cm3 (varies with ratio) |

| Melting Point | 1455degC | 1400-1450degC |

| Magnetic Properties | Ferromagnetic up to 358degC (Curie point) | Strong ferromagnet, higher saturation magnetization |

| Corrosion Resistance | Excellent in many environments | Good, enhanced in specific alloys |

| Common Applications | Coinage, batteries, plating, electronics | Magnetic cores, precision instruments, aerospace components |

| Electrical Resistivity | 6.99 mO*cm | Lower than pure nickel, varies with alloy |

Composition Differences: Pure Nickel vs Nickel-Iron Alloy

Pure nickel consists of nearly 99.9% nickel, characterized by its high magnetic permeability and corrosion resistance, making it ideal for industrial applications requiring purity. Nickel-iron alloys, such as permalloy, combine nickel with iron typically ranging from 20% to 50%, enhancing magnetic properties like permeability and coercivity while reducing electrical resistivity. The compositional variation directly influences mechanical strength, thermal stability, and electrical conductivity, tailoring each material for specific electromagnetic and structural uses.

Physical Properties Comparison

Pure nickel exhibits a melting point of 1455degC and a density of 8.90 g/cm3, whereas nickel-iron alloys typically have lower melting points around 1400degC and densities ranging from 8.0 to 8.5 g/cm3 depending on the iron content. The magnetic permeability of nickel-iron alloys greatly surpasses that of pure nickel, with some alloys reaching permeabilities up to 100,000, compared to pure nickel's permeability of approximately 600. Hardness and tensile strength also vary, with nickel-iron alloys generally showing increased hardness and strength due to the iron's reinforcing effect on the nickel matrix.

Corrosion Resistance: Which Performs Better?

Pure nickel exhibits excellent corrosion resistance in acidic and alkaline environments due to its dense passive oxide layer, making it highly effective against various industrial corrosive agents. Nickel-iron alloys, such as permalloy, provide enhanced mechanical strength but may demonstrate slightly reduced corrosion resistance compared to pure nickel, especially in oxidizing environments. In applications requiring superior resistance to chemical corrosion, pure nickel often outperforms nickel-iron alloys, while alloys may be preferred for combined corrosion and structural performance.

Electrical Conductivity Analysis

Pure nickel exhibits high electrical conductivity due to its uniform atomic structure, making it ideal for applications requiring efficient current flow. In contrast, nickel-iron alloys show reduced electrical conductivity because the presence of iron atoms disrupts electron movement and increases resistivity. Electrical conductivity analysis reveals that nickel-iron alloys typically conduct at a fraction of pure nickel's efficiency, balancing enhanced magnetic properties with electrical performance trade-offs.

Magnetic Characteristics: Nickel vs Nickel-Iron Alloy

Pure nickel exhibits strong ferromagnetic properties with a high magnetic permeability and a Curie temperature of around 358degC, making it highly effective for magnetic applications. Nickel-iron alloys, such as Permalloy, offer enhanced magnetic softness, reduced coercivity, and higher magnetic permeability than pure nickel, which improves their performance in sensitive electromagnetic devices like transformers and inductors. The addition of iron to nickel alters the crystal lattice and magnetic domain structure, resulting in superior magnetic characteristics tailored for precision electronic components.

Industrial Applications and Usage

Pure nickel is highly valued in industrial applications for its excellent corrosion resistance and high thermal conductivity, making it ideal for use in chemical processing equipment, batteries, and stainless steel production. Nickel-iron alloys, such as Invar, are crucial in precision instruments and aerospace components due to their low thermal expansion and enhanced mechanical strength. Industries prioritize pure nickel for electroplating and coinage, while nickel-iron alloys dominate structural and magnetic applications requiring dimensional stability under temperature fluctuations.

Fabrication and Processing Differences

Pure nickel exhibits excellent corrosion resistance and ductility, making it suitable for applications requiring precise fabrication techniques such as electroforming and cold rolling. In contrast, nickel-iron alloys, like those used in Invar, require specialized heat treatment and controlled cooling processes to maintain dimensional stability and magnetic properties during fabrication. The processing of nickel-iron alloys often involves more complex alloying and annealing steps compared to the relatively straightforward melting and refining of pure nickel.

Cost and Availability Factors

Pure nickel commands a higher price due to its extensive industrial applications and relative scarcity compared to nickel-iron alloys, which combine nickel with iron to reduce costs. Nickel-iron alloys benefit from greater availability and lower production expenses, making them a cost-effective alternative in large-scale manufacturing. Market fluctuations in nickel ore supply directly impact pure nickel pricing, while nickel-iron alloys experience more stable cost dynamics due to iron's abundance.

Environmental and Health Considerations

Pure nickel exhibits excellent corrosion resistance and low toxicity, making it safer for various industrial applications, while nickel-iron alloys may pose increased environmental risks due to potential nickel ion release and higher magnetic properties affecting waste management. The extraction and refining processes of pure nickel typically result in lower airborne particulate emissions compared to complex nickel-iron alloys, which often require intensive energy consumption and generate more hazardous byproducts. Careful handling and proper disposal protocols are essential for both materials to minimize occupational exposure and environmental contamination, with pure nickel favored in contexts demanding stricter health and safety compliance.

Choosing the Right Material for Your Project

Pure nickel offers superior corrosion resistance and excellent thermal conductivity, making it ideal for chemical processing and electronics applications. Nickel-iron alloys, combining strength and magnetic properties, suit structural components and electromagnets where durability and magnetic response are critical. Selecting the right material depends on balancing corrosion resistance, mechanical strength, and magnetic performance requirements specific to your project's environment and functional demands.

Pure Nickel vs Nickel-Iron Alloy Infographic

materialdif.com

materialdif.com