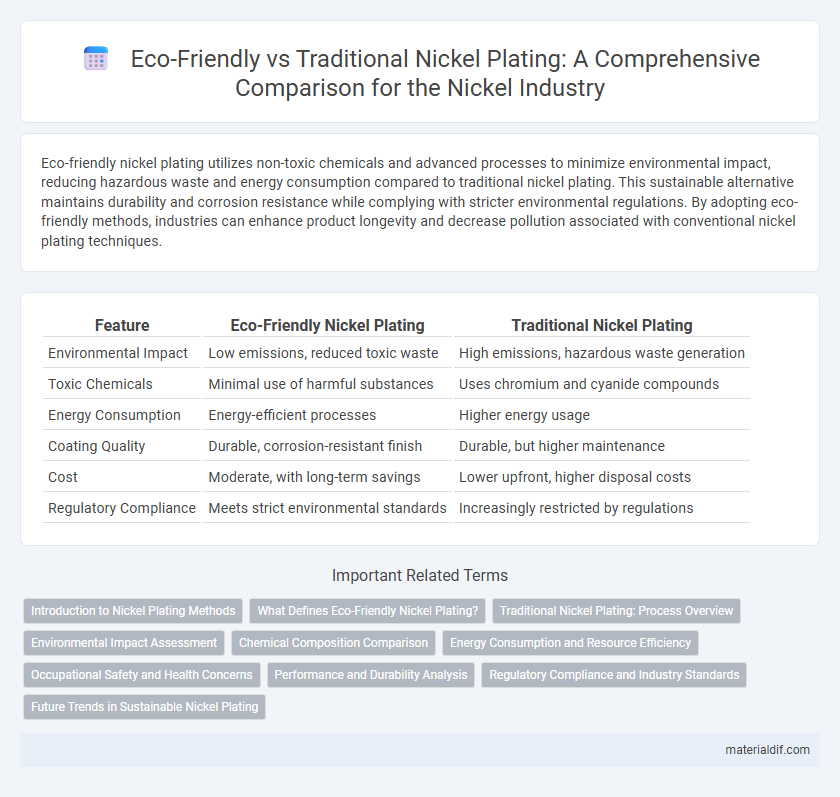

Eco-friendly nickel plating utilizes non-toxic chemicals and advanced processes to minimize environmental impact, reducing hazardous waste and energy consumption compared to traditional nickel plating. This sustainable alternative maintains durability and corrosion resistance while complying with stricter environmental regulations. By adopting eco-friendly methods, industries can enhance product longevity and decrease pollution associated with conventional nickel plating techniques.

Table of Comparison

| Feature | Eco-Friendly Nickel Plating | Traditional Nickel Plating |

|---|---|---|

| Environmental Impact | Low emissions, reduced toxic waste | High emissions, hazardous waste generation |

| Toxic Chemicals | Minimal use of harmful substances | Uses chromium and cyanide compounds |

| Energy Consumption | Energy-efficient processes | Higher energy usage |

| Coating Quality | Durable, corrosion-resistant finish | Durable, but higher maintenance |

| Cost | Moderate, with long-term savings | Lower upfront, higher disposal costs |

| Regulatory Compliance | Meets strict environmental standards | Increasingly restricted by regulations |

Introduction to Nickel Plating Methods

Eco-friendly nickel plating utilizes advanced techniques such as pulse electroplating and trivalent nickel baths to reduce hazardous chemicals and lower environmental impact compared to traditional hexavalent nickel plating. This method decreases toxic waste and energy consumption while maintaining corrosion resistance and surface finish quality. Traditional nickel plating, often involving toxic hexavalent chromium, poses significant environmental and health risks due to toxic byproducts and higher chemical usage.

What Defines Eco-Friendly Nickel Plating?

Eco-friendly nickel plating utilizes advanced technologies such as pulse plating and trivalent nickel baths to reduce toxic waste and lower energy consumption compared to traditional hexavalent nickel plating methods. This process significantly minimizes the release of hazardous substances like hexavalent chromium and heavy metals into the environment, promoting sustainability in industrial applications. Strict adherence to environmental regulations and adoption of water recycling systems further define eco-friendly nickel plating by ensuring safer and cleaner production outcomes.

Traditional Nickel Plating: Process Overview

Traditional nickel plating involves electroplating a layer of nickel onto a metal substrate using a chemical bath containing nickel salts and electrolytes. This process requires the application of an electric current to reduce nickel ions onto the target surface, creating corrosion-resistant and decorative coatings. However, it often utilizes hazardous chemicals such as nickel sulfate and potassium dichromate, which pose environmental and health risks due to toxic waste and heavy metal contamination.

Environmental Impact Assessment

Eco-friendly nickel plating significantly reduces the release of hazardous chemicals such as hexavalent chromium and acid mist, minimizing water and air pollution compared to traditional nickel plating methods. The adoption of sustainable processes like electroless nickel plating with non-toxic additives and advanced wastewater treatment systems drastically lowers toxic sludge generation and energy consumption. Environmental impact assessments highlight that eco-friendly nickel plating offers improved compliance with stringent regulations, enhancing workplace safety and reducing ecological footprints.

Chemical Composition Comparison

Eco-friendly nickel plating utilizes trivalent chromium-based solutions, significantly reducing hexavalent chromium and heavy metal content found in traditional hexavalent chromium formulations. This shift in chemical composition minimizes toxic emissions and hazardous waste while maintaining corrosion resistance and finishing quality. The environmentally benign alternatives also employ organic additives and lower concentrations of nickel salts to further decrease ecological impact during the plating process.

Energy Consumption and Resource Efficiency

Eco-friendly nickel plating significantly reduces energy consumption by utilizing low-temperature processes and advanced electrolytic solutions, which minimize electrical power usage compared to traditional high-temperature plating methods. Resource efficiency is enhanced through closed-loop recycling systems that reclaim nickel and plating chemicals, curbing raw material depletion and waste generation. These innovations lead to lower environmental impact and sustainable production in the metal finishing industry.

Occupational Safety and Health Concerns

Eco-friendly nickel plating uses less toxic chemicals, significantly reducing workers' exposure to hazardous substances like hexavalent chromium, a known carcinogen in traditional nickel plating. Advanced ventilation and closed-loop systems in eco-friendly processes minimize inhalation risks and skin contact, enhancing occupational health standards. These improvements lead to lower rates of respiratory illnesses and skin sensitization among plating workers compared to conventional methods.

Performance and Durability Analysis

Eco-friendly nickel plating uses advanced organic solvents and reduced toxic compounds, enhancing corrosion resistance and providing comparable hardness to traditional plating methods. This sustainable approach maintains excellent adhesion and wear resistance while lowering environmental impact through decreased hazardous waste and energy consumption. Performance tests show eco-friendly coatings deliver durable protection suitable for automotive, electronics, and industrial applications without compromising long-term durability.

Regulatory Compliance and Industry Standards

Eco-friendly nickel plating methods reduce environmental impact by minimizing the use of toxic chemicals such as hexavalent chromium, aligning with stringent regulatory frameworks like the REACH and RoHS directives. These techniques often incorporate trivalent chromium processes and improved waste treatment systems, ensuring compliance with industry standards such as ISO 14001 for environmental management. In contrast, traditional nickel plating may face increasing restrictions due to its use of hazardous substances, compelling manufacturers to adopt greener alternatives to meet evolving global compliance requirements.

Future Trends in Sustainable Nickel Plating

Eco-friendly nickel plating utilizes advanced processes such as electrodeposition with reduced toxic chemicals and increased use of recycling methods, significantly lowering environmental impact compared to traditional nickel plating. Future trends emphasize the integration of nanotechnology to enhance coating durability while minimizing resource consumption and waste generation. Emerging techniques like pulse plating and biodegradable electrolyte solutions are positioned to revolutionize sustainable nickel plating by improving efficiency and reducing hazardous byproducts.

Eco-Friendly Nickel Plating vs Traditional Nickel Plating Infographic

materialdif.com

materialdif.com