Nickel Alloy and Inconel are both high-performance materials used in demanding applications, but they differ in composition and properties. Nickel alloys encompass a broad range of corrosion-resistant and heat-resistant metals, while Inconel is a specific trademarked nickel-chromium-based superalloy known for exceptional strength and oxidation resistance at extreme temperatures. Choosing between Nickel Alloy and Inconel depends on the required thermal stability, mechanical strength, and environmental conditions of the project.

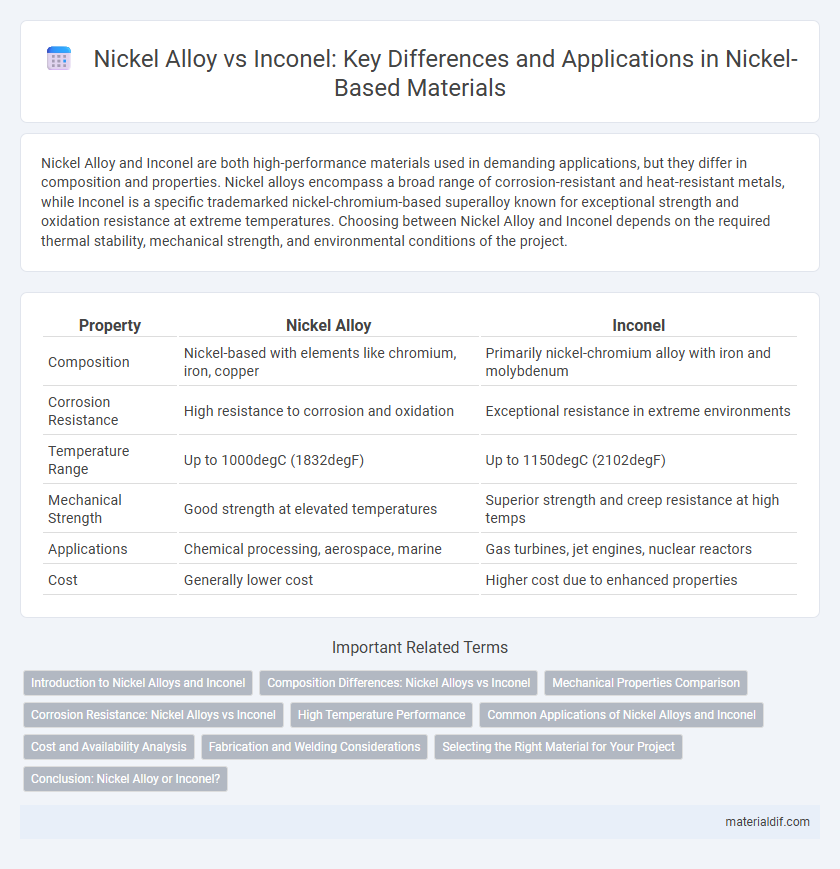

Table of Comparison

| Property | Nickel Alloy | Inconel |

|---|---|---|

| Composition | Nickel-based with elements like chromium, iron, copper | Primarily nickel-chromium alloy with iron and molybdenum |

| Corrosion Resistance | High resistance to corrosion and oxidation | Exceptional resistance in extreme environments |

| Temperature Range | Up to 1000degC (1832degF) | Up to 1150degC (2102degF) |

| Mechanical Strength | Good strength at elevated temperatures | Superior strength and creep resistance at high temps |

| Applications | Chemical processing, aerospace, marine | Gas turbines, jet engines, nuclear reactors |

| Cost | Generally lower cost | Higher cost due to enhanced properties |

Introduction to Nickel Alloys and Inconel

Nickel alloys are engineered materials known for exceptional corrosion resistance, high strength, and excellent performance in extreme environments, making them ideal for aerospace, chemical processing, and marine applications. Inconel, a trademarked family of nickel-chromium-based superalloys, offers superior oxidation and corrosion resistance at high temperatures, widely used in gas turbines, heat exchangers, and nuclear reactors. Both nickel alloys and Inconel provide critical solutions in industries requiring durability under severe thermal and chemical stress.

Composition Differences: Nickel Alloys vs Inconel

Nickel alloys encompass a broad category of metal blends with varying amounts of nickel combined with elements like chromium, iron, and copper to enhance corrosion resistance and mechanical strength. Inconel is a specific family of nickel-chromium-based superalloys characterized by a high percentage of nickel, usually 50% or more, combined with chromium, iron, and other trace elements that provide exceptional oxidation and heat resistance. The primary compositional difference lies in Inconel's tailored chromium content, typically around 20-23%, and the precise balance of other alloying elements designed for extreme environments, setting it apart from more general nickel alloys used across diverse industrial applications.

Mechanical Properties Comparison

Nickel alloys exhibit high tensile strength and excellent corrosion resistance, making them suitable for a wide range of industrial applications. Inconel, a specific nickel-chromium-based superalloy, offers superior mechanical properties such as exceptional creep resistance and high-temperature stability up to 1,000degC. The key difference lies in Inconel's enhanced performance under extreme environments, including resistance to oxidation and thermal fatigue, compared to standard nickel alloys.

Corrosion Resistance: Nickel Alloys vs Inconel

Nickel alloys exhibit excellent corrosion resistance across various harsh environments, including acidic and alkaline conditions, due to their high nickel content and addition of elements like molybdenum. Inconel, a specific family of nickel-chromium-based superalloys, offers superior oxidation and high-temperature corrosion resistance, especially in aerospace and chemical processing industries. The choice between generic nickel alloys and Inconel depends on the required resistance to extreme temperatures and aggressive chemical exposure.

High Temperature Performance

Nickel alloys and Inconel both excel in high-temperature performance, with Inconel specifically engineered to maintain strength and oxidation resistance at extreme temperatures exceeding 1,000degC. Inconel's unique composition, rich in nickel, chromium, and iron, provides superior creep resistance and corrosion protection under thermal stress, outperforming many standard nickel alloys. These properties make Inconel ideal for aerospace, power generation, and chemical processing applications where sustained exposure to harsh environments is critical.

Common Applications of Nickel Alloys and Inconel

Nickel alloys, known for their exceptional corrosion resistance and high-temperature strength, are widely used in chemical processing, aerospace, and power generation industries. Inconel, a specific group of nickel-chromium-based superalloys, excels in extreme environments such as jet engines, gas turbines, and nuclear reactors due to its superior oxidation and heat resistance. Both nickel alloys and Inconel are critical in applications requiring durability under harsh conditions, with Inconel favored for more demanding thermal and mechanical stresses.

Cost and Availability Analysis

Nickel alloys generally offer lower costs and greater availability compared to Inconel, which is a specialized high-performance nickel-chromium alloy used primarily in extreme environments like aerospace and chemical processing. The raw materials for common nickel alloys are more abundant and less expensive, making them suitable for broader industrial applications with moderate temperature and corrosion requirements. Inconel's higher price reflects its superior resistance to oxidation, heat, and corrosive conditions, limiting its availability to niche sectors where performance justifies the cost.

Fabrication and Welding Considerations

Nickel alloys and Inconel exhibit distinct fabrication and welding characteristics critical for high-performance applications. Nickel alloys generally offer excellent corrosion resistance and ease of machining, but their welding requires controlled heat input to prevent cracking and maintain mechanical properties. Inconel, a specific family of nickel-chromium-based superalloys, demands precise welding techniques such as TIG or laser welding, with preheating and post-weld heat treatment essential to avoid stress corrosion cracking and ensure optimal joint integrity.

Selecting the Right Material for Your Project

Nickel alloys and Inconel offer distinct advantages depending on project requirements such as corrosion resistance, temperature tolerance, and mechanical strength. Nickel alloys provide versatility across various industrial applications due to their excellent resistance to oxidation and chemical degradation. Inconel, a specific nickel-chromium-based superalloy, excels in extreme environments requiring high-performance durability, especially in aerospace and power generation industries.

Conclusion: Nickel Alloy or Inconel?

Nickel alloys offer a broad range of compositions tailored for specific industrial needs, providing excellent corrosion resistance and mechanical strength in various environments. Inconel, a trademarked family of high-performance nickel-chromium-based superalloys, excels in extreme temperature and oxidative conditions, making it ideal for aerospace, chemical processing, and power generation applications. Choosing between nickel alloy and Inconel depends on the operational demands, with Inconel preferred for high-temperature durability and nickel alloys favored for versatile corrosion resistance in less extreme environments.

Nickel Alloy vs Inconel Infographic

materialdif.com

materialdif.com