Alloy 600 and Alloy 625 are both nickel-based alloys widely used in high-temperature and corrosive environments, but Alloy 625 offers superior strength and corrosion resistance due to its higher molybdenum and niobium content. Alloy 600 is favored for its excellent resistance to oxidation and moderate corrosion resistance, making it suitable for furnace parts and heat exchangers. In contrast, Alloy 625 is preferred in aerospace and marine applications where enhanced mechanical properties and resistance to pitting and crevice corrosion are critical.

Table of Comparison

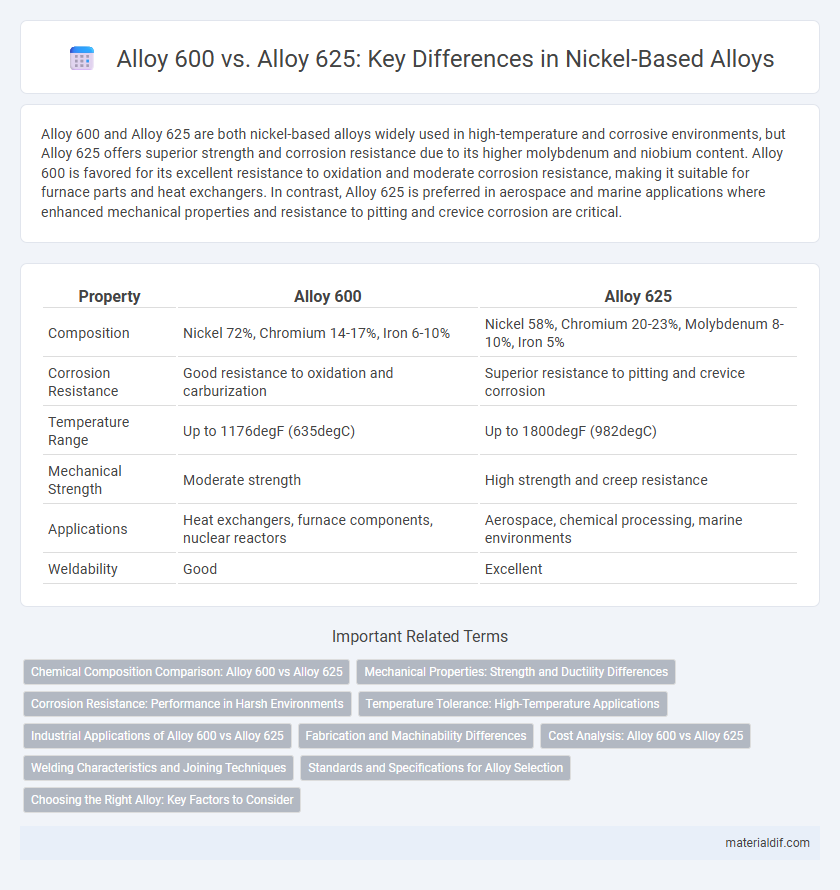

| Property | Alloy 600 | Alloy 625 |

|---|---|---|

| Composition | Nickel 72%, Chromium 14-17%, Iron 6-10% | Nickel 58%, Chromium 20-23%, Molybdenum 8-10%, Iron 5% |

| Corrosion Resistance | Good resistance to oxidation and carburization | Superior resistance to pitting and crevice corrosion |

| Temperature Range | Up to 1176degF (635degC) | Up to 1800degF (982degC) |

| Mechanical Strength | Moderate strength | High strength and creep resistance |

| Applications | Heat exchangers, furnace components, nuclear reactors | Aerospace, chemical processing, marine environments |

| Weldability | Good | Excellent |

Chemical Composition Comparison: Alloy 600 vs Alloy 625

Alloy 600 primarily consists of approximately 72% nickel, 14-17% chromium, and 6-10% iron, offering excellent corrosion resistance and high-temperature strength. In contrast, Alloy 625 contains about 58% nickel, 20-23% chromium, 8-10% molybdenum, and 3.15-4.15% niobium, enhancing its resistance to pitting, crevice corrosion, and oxidizing environments. The higher molybdenum and niobium content in Alloy 625 significantly improves its mechanical properties and corrosion resistance compared to Alloy 600.

Mechanical Properties: Strength and Ductility Differences

Alloy 600 exhibits moderate tensile strength and high ductility, making it suitable for applications requiring good formability and resistance to stress corrosion cracking at elevated temperatures. In contrast, Alloy 625 offers superior tensile strength and enhanced creep resistance due to its high niobium and molybdenum content, while maintaining excellent ductility under high-stress environments. These mechanical property differences position Alloy 625 as the preferred choice for high-temperature, high-stress applications, whereas Alloy 600 is favored for less demanding conditions requiring good tensile strength and flexibility.

Corrosion Resistance: Performance in Harsh Environments

Alloy 625 exhibits superior corrosion resistance compared to Alloy 600, particularly in environments containing chlorides, sulfur compounds, and acidic media. The higher molybdenum and niobium content in Alloy 625 enhances its ability to withstand pitting, crevice corrosion, and stress corrosion cracking, making it ideal for harsh chemical processing and marine applications. Alloy 600, while resistant to oxidation and high temperatures, is more susceptible to stress corrosion cracking in chloride-rich environments.

Temperature Tolerance: High-Temperature Applications

Alloy 625 exhibits superior temperature tolerance compared to Alloy 600, performing reliably in environments up to 982degC (1800degF), whereas Alloy 600 is generally limited to 704degC (1300degF). The higher nickel, molybdenum, and chromium content in Alloy 625 enhances its resistance to oxidation and creep at elevated temperatures. These properties make Alloy 625 the preferred choice for high-temperature applications such as aerospace, chemical processing, and power generation.

Industrial Applications of Alloy 600 vs Alloy 625

Alloy 600, primarily composed of nickel with significant chromium and iron content, excels in high-temperature environments such as furnace components and heat exchangers due to its excellent oxidation resistance and strength. Alloy 625 contains higher nickel content and added molybdenum, offering superior corrosion resistance and mechanical properties ideal for chemical processing, marine engineering, and aerospace industries. Industrial applications favor Alloy 600 in nuclear reactors and gas turbines, while Alloy 625 is preferred for seawater and acidic environment equipment.

Fabrication and Machinability Differences

Alloy 600 and Alloy 625 differ significantly in fabrication and machinability, with Alloy 600 offering superior ease of welding and forming due to its simpler chemical composition of approximately 72% nickel, 14-17% chromium, and 6-10% iron. Alloy 625 contains higher amounts of molybdenum (8-10%) and niobium (3-4%), enhancing corrosion resistance but reducing machinability and requiring specialized tooling and slower machining speeds. Fabricators often prefer Alloy 600 for applications demanding extensive forming and welding, while Alloy 625 is chosen for service environments where high strength and corrosion resistance outweigh fabrication complexities.

Cost Analysis: Alloy 600 vs Alloy 625

Alloy 600 typically offers a lower material cost compared to Alloy 625 due to its simpler nickel-chromium-iron composition, making it economically favorable for applications with moderate corrosion resistance requirements. Alloy 625, enriched with nickel, chromium, molybdenum, and iron, demands higher raw material expenses but delivers superior strength and corrosion resistance, which can reduce maintenance and replacement costs over time. Evaluating the total cost of ownership, Alloy 625 often presents greater value in harsh environments despite its initial higher price, especially in chemical processing and marine applications.

Welding Characteristics and Joining Techniques

Alloy 600 exhibits excellent weldability with minimal risk of hot cracking due to its stable austenitic structure, making it suitable for conventional welding methods like TIG and MIG. Alloy 625, while also weldable, demands more precise control during welding to prevent cracking and maintain its superior corrosion resistance, often requiring post-weld heat treatment to alleviate stresses. Joining techniques for Alloy 625 typically involve specialized filler materials and careful thermal management to preserve mechanical integrity, contrasting with Alloy 600's more straightforward welding process.

Standards and Specifications for Alloy Selection

Alloy 600 conforms primarily to ASTM B166 for seamless nickel alloy tubing and ASTM B127 for nickel bar and shapes, making it suitable for high-temperature applications and corrosion resistance in chemical environments. Alloy 625 meets ASTM B443 for seamless nickel alloy tubing and ASTM B444 for welded nickel alloy tubing, offering superior strength and oxidation resistance in aerospace and marine applications. Selection between Alloy 600 and Alloy 625 depends on specific ASTM standards requirements, mechanical properties, and environmental conditions outlined in ASME and UNS classifications.

Choosing the Right Alloy: Key Factors to Consider

When choosing between Alloy 600 and Alloy 625, consider factors such as corrosion resistance, mechanical strength, and temperature tolerance; Alloy 625 offers superior resistance to pitting, crevice corrosion, and stress corrosion cracking, making it ideal for aggressive chemical environments. Alloy 600 provides excellent oxidation resistance and maintains structural integrity at high temperatures up to 1200degF (650degC), which suits applications like heat exchangers and furnace components. Evaluating the specific environmental conditions and mechanical requirements ensures optimal alloy selection for enhanced performance and durability.

Alloy 600 vs Alloy 625 Infographic

materialdif.com

materialdif.com