Pure nickel offers superior corrosion resistance and conductivity, making it ideal for high-performance applications in electronics and batteries. Nickel-coated materials provide enhanced surface protection and wear resistance without the high cost of solid nickel. Choosing between pure nickel and nickel-coated depends on the balance of durability, cost, and application requirements.

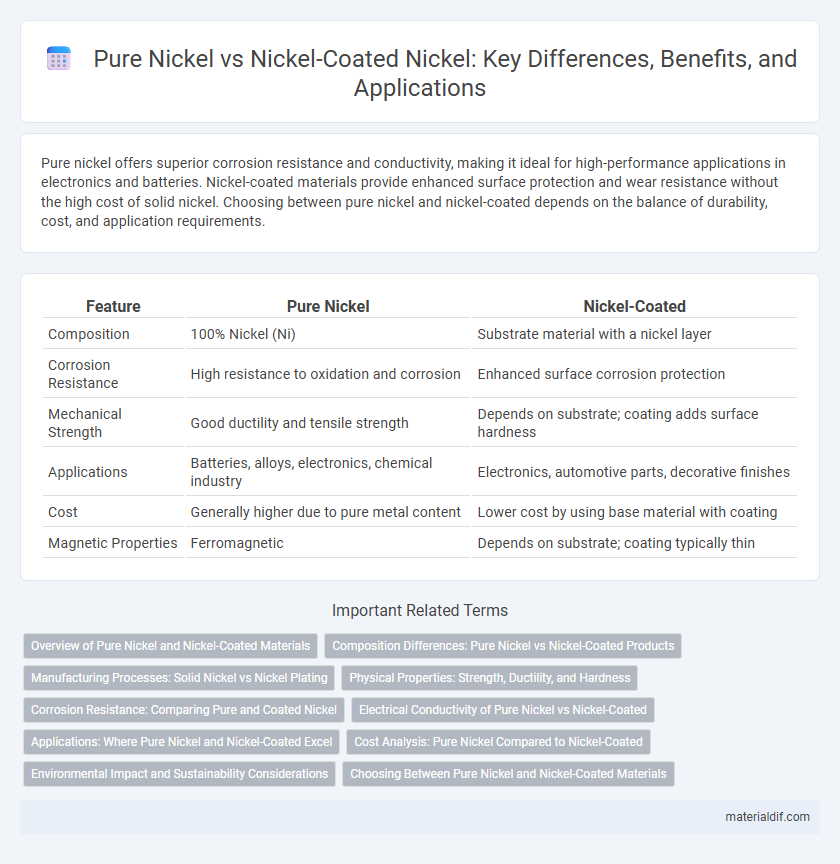

Table of Comparison

| Feature | Pure Nickel | Nickel-Coated |

|---|---|---|

| Composition | 100% Nickel (Ni) | Substrate material with a nickel layer |

| Corrosion Resistance | High resistance to oxidation and corrosion | Enhanced surface corrosion protection |

| Mechanical Strength | Good ductility and tensile strength | Depends on substrate; coating adds surface hardness |

| Applications | Batteries, alloys, electronics, chemical industry | Electronics, automotive parts, decorative finishes |

| Cost | Generally higher due to pure metal content | Lower cost by using base material with coating |

| Magnetic Properties | Ferromagnetic | Depends on substrate; coating typically thin |

Overview of Pure Nickel and Nickel-Coated Materials

Pure nickel offers exceptional corrosion resistance, high thermal conductivity, and excellent mechanical strength, making it ideal for aerospace and chemical processing applications. Nickel-coated materials enhance surface properties by providing additional wear resistance, improved hardness, and protection against oxidation while maintaining the underlying substrate's structural integrity. Both forms are crucial in industrial settings, with pure nickel favored for its inherent durability and nickel coatings applied to extend lifespan and performance of less resistant base metals.

Composition Differences: Pure Nickel vs Nickel-Coated Products

Pure nickel consists of nearly 99.9% nickel content, ensuring superior corrosion resistance and high thermal conductivity, making it ideal for industrial applications demanding durability. Nickel-coated products feature a base metal, commonly steel or copper, layered with a thin nickel plating that provides surface protection, enhanced wear resistance, and improved aesthetic appeal while reducing material costs. The composition differences significantly impact performance, with pure nickel excelling in environments requiring exceptional purity and nickel-coated materials balancing cost efficiency with adequate nickel properties.

Manufacturing Processes: Solid Nickel vs Nickel Plating

Pure nickel is produced through refining and electrolysis, resulting in solid metal sheets or bars with high corrosion resistance and strength. Nickel plating involves depositing a thin layer of nickel onto a substrate using electroplating, providing surface protection and enhanced appearance without the bulk properties of solid nickel. Manufacturing solid nickel requires intensive melting and casting, while nickel coating relies on controlled electrochemical processes for uniform layer application.

Physical Properties: Strength, Ductility, and Hardness

Pure nickel exhibits high ductility and moderate strength, making it highly malleable for various industrial applications, while its hardness is relatively low compared to coated alternatives. Nickel-coated materials enhance surface hardness significantly, providing superior wear resistance and improved strength without compromising the substrate's ductility. These physical property differences are critical when selecting materials for applications requiring a balance between durability and flexibility, such as in aerospace and electronics.

Corrosion Resistance: Comparing Pure and Coated Nickel

Pure nickel exhibits impressive corrosion resistance due to its stable oxide layer that protects it in various environments, including acidic and alkaline conditions. Nickel-coated materials enhance corrosion resistance by providing a protective surface barrier that prevents substrate oxidation and improves durability against moisture, salts, and chemical exposure. While pure nickel offers consistent resistance inherently, nickel coatings are often preferred for cost-effective protection on less corrosion-resistant base metals.

Electrical Conductivity of Pure Nickel vs Nickel-Coated

Pure nickel exhibits higher electrical conductivity compared to nickel-coated materials due to the absence of an insulating layer, allowing electrons to flow more freely through the metal lattice. Nickel coatings, often applied over substrates like steel or copper, introduce an interfacial barrier and potential impurities that reduce overall conductivity. This makes pure nickel preferable for applications requiring efficient electrical performance, such as in battery electrodes and resistance wires.

Applications: Where Pure Nickel and Nickel-Coated Excel

Pure nickel excels in high-temperature and highly corrosive environments, making it ideal for aerospace components, chemical processing equipment, and batteries where purity ensures optimal performance and resistance. Nickel-coated materials provide enhanced wear resistance and corrosion protection in applications such as electronics, automotive parts, and plumbing fixtures, where cost-effective and durable surface treatment is crucial. Both forms leverage nickel's unique properties, but pure nickel is preferred for critical, demanding conditions while nickel coatings optimize performance in less extreme but abrasion-prone applications.

Cost Analysis: Pure Nickel Compared to Nickel-Coated

Pure nickel commands a higher market price due to its superior purity and enhanced corrosion resistance, making it a preferred choice for critical industrial applications. Nickel-coated materials offer a cost-effective alternative by applying a thin layer of nickel over a base metal, significantly reducing raw material expenses while maintaining adequate surface protection. The overall cost savings of nickel-coated products become pronounced in large-scale manufacturing where material performance tolerances are flexible.

Environmental Impact and Sustainability Considerations

Pure nickel offers higher recyclability and lower environmental toxicity compared to nickel-coated materials, which often involve additional layers containing hazardous substances. The production and disposal of nickel-coated products can introduce heavy metals and chemical contaminants into ecosystems, increasing environmental risks. Sustainable practices favor pure nickel due to its easier recovery in recycling processes and reduced reliance on harmful coatings.

Choosing Between Pure Nickel and Nickel-Coated Materials

Pure nickel offers superior corrosion resistance and electrical conductivity, making it ideal for demanding industrial applications such as battery electrodes and chemical processing equipment. Nickel-coated materials, featuring a thin layer of nickel over a base metal, provide cost-effective protection against oxidation and wear while enhancing surface hardness and appearance. Selecting between pure nickel and nickel-coated materials depends on factors like budget constraints, environmental exposure, mechanical requirements, and desired longevity.

Pure nickel vs Nickel-coated Infographic

materialdif.com

materialdif.com