Nickel mesh offers higher tensile strength and durability, making it ideal for applications requiring mechanical stability, while nickel foam provides a greater surface area and porosity, enhancing electrochemical performance in batteries and supercapacitors. The porous structure of nickel foam facilitates better electrolyte penetration and faster ion transport compared to the denser nickel mesh. Choosing between nickel mesh and nickel foam depends on balancing mechanical robustness with electrochemical efficiency for specific nickel-based electrode designs.

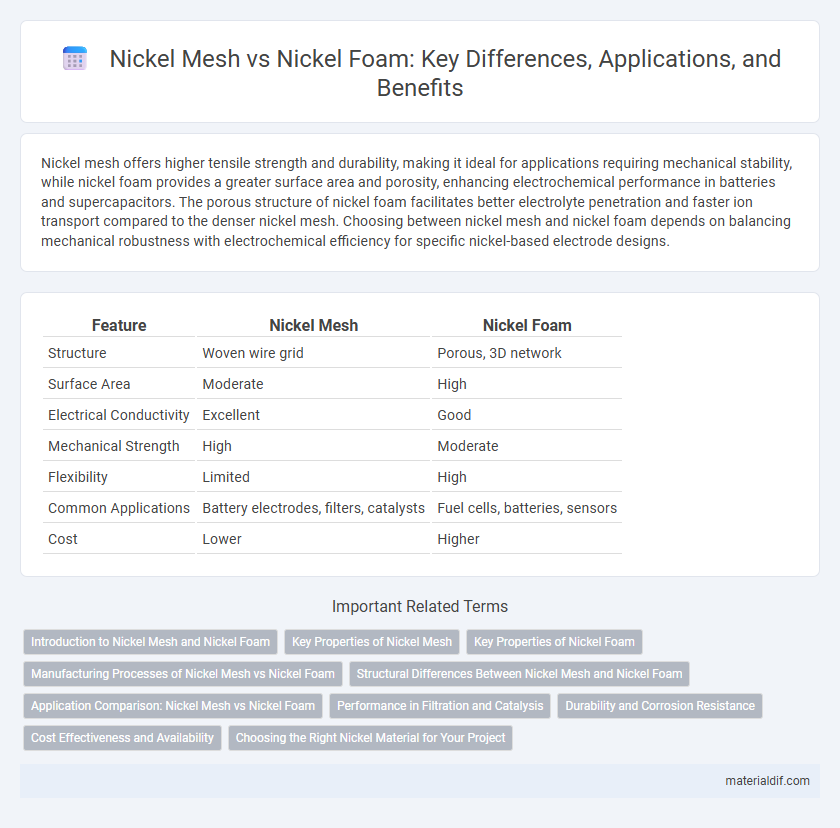

Table of Comparison

| Feature | Nickel Mesh | Nickel Foam |

|---|---|---|

| Structure | Woven wire grid | Porous, 3D network |

| Surface Area | Moderate | High |

| Electrical Conductivity | Excellent | Good |

| Mechanical Strength | High | Moderate |

| Flexibility | Limited | High |

| Common Applications | Battery electrodes, filters, catalysts | Fuel cells, batteries, sensors |

| Cost | Lower | Higher |

Introduction to Nickel Mesh and Nickel Foam

Nickel mesh is a woven metal fabric characterized by its rigidity and high tensile strength, making it ideal for filtration, battery electrodes, and catalysts. Nickel foam, a porous and lightweight material, offers excellent electrical conductivity and large surface area, frequently used in energy storage and electrochemical applications. Both materials leverage nickel's corrosion resistance while serving distinct roles based on structural and functional differences.

Key Properties of Nickel Mesh

Nickel mesh exhibits superior mechanical strength and corrosion resistance compared to nickel foam, making it ideal for high-wear applications. Its uniform pore size and high surface area enhance catalytic performance and efficient fluid flow in batteries and filtration systems. The rigid structure of nickel mesh also supports repeated use and easier cleaning, distinguishing it from the more flexible, less durable nickel foam.

Key Properties of Nickel Foam

Nickel foam features a highly porous structure with a large surface area, providing excellent electrical conductivity and superior catalytic properties compared to nickel mesh. Its high mechanical strength and flexibility enable effective absorption and distribution of gases and liquids in applications such as fuel cells and batteries. The open-cell architecture also enhances corrosion resistance, making nickel foam ideal for energy storage and filtration systems.

Manufacturing Processes of Nickel Mesh vs Nickel Foam

Nickel mesh is manufactured through precision weaving or embossing processes that interlock nickel wires into a stable grid structure, offering high mechanical strength and uniform pore distribution. In contrast, nickel foam is produced via a chemical vapor deposition or electroplating process onto a polymer template, which is later removed, resulting in a highly porous, three-dimensional network with superior surface area. The manufacturing differences significantly influence the material properties, making nickel mesh ideal for applications requiring structural integrity, while nickel foam suits catalytic and filtration uses due to its enhanced porosity.

Structural Differences Between Nickel Mesh and Nickel Foam

Nickel mesh consists of woven or welded metal wires forming a grid-like structure with uniform pore sizes, providing high mechanical strength and rigidity. Nickel foam features a porous, sponge-like architecture with interconnected pores that offer increased surface area and enhanced flexibility but lower structural strength compared to mesh. These differences impact their applications, with mesh suited for filtration and structural support, while foam excels in battery electrodes and catalytic substrates.

Application Comparison: Nickel Mesh vs Nickel Foam

Nickel mesh offers superior mechanical strength and electrical conductivity, making it ideal for applications in battery electrodes, filtration systems, and catalysts where durability and efficient electron transfer are critical. Nickel foam provides a high surface area with a porous structure, enhancing use in energy storage devices like fuel cells and supercapacitors due to improved electrolyte penetration and active material loading. Both materials serve crucial roles in electrochemical applications, but nickel mesh favors structural stability while nickel foam optimizes surface interaction and material accessibility.

Performance in Filtration and Catalysis

Nickel mesh offers high mechanical strength and uniform pore distribution, enhancing filtration precision and durability in catalytic applications. Nickel foam provides superior surface area and porosity, significantly improving catalytic activity and mass transfer efficiency. Choice between them depends on the specific filtration or catalytic performance requirements, with foam excelling in reaction rates and mesh favored for structural stability.

Durability and Corrosion Resistance

Nickel mesh exhibits higher durability due to its woven structure, which provides enhanced mechanical strength compared to the porous, less dense framework of nickel foam. The corrosion resistance of nickel mesh is superior as its compact construction limits exposure to corrosive environments, while nickel foam's open-cell design is more susceptible to oxidation and degradation over time. Both materials benefit from nickel's inherent resistance to oxidation, but nickel mesh outperforms nickel foam in harsh chemical and high-temperature conditions.

Cost Effectiveness and Availability

Nickel mesh offers greater cost effectiveness due to its lower production costs and higher availability, making it suitable for large-scale industrial applications. Nickel foam, although providing superior surface area and conductivity, is typically more expensive and less readily available in bulk quantities. Industries seeking budget-friendly and easily sourced materials often prefer nickel mesh for electrochemical and filtration uses.

Choosing the Right Nickel Material for Your Project

Nickel mesh offers precise filtration and excellent mechanical strength, making it ideal for applications requiring high durability and fine particle retention. Nickel foam provides superior surface area and enhanced conductivity, favoring catalytic and battery applications where lightweight and porous structures improve performance. Selecting between nickel mesh and nickel foam depends on balancing factors like filtration efficiency, mechanical resilience, electrical conductivity, and specific project requirements.

Nickel mesh vs nickel foam Infographic

materialdif.com

materialdif.com