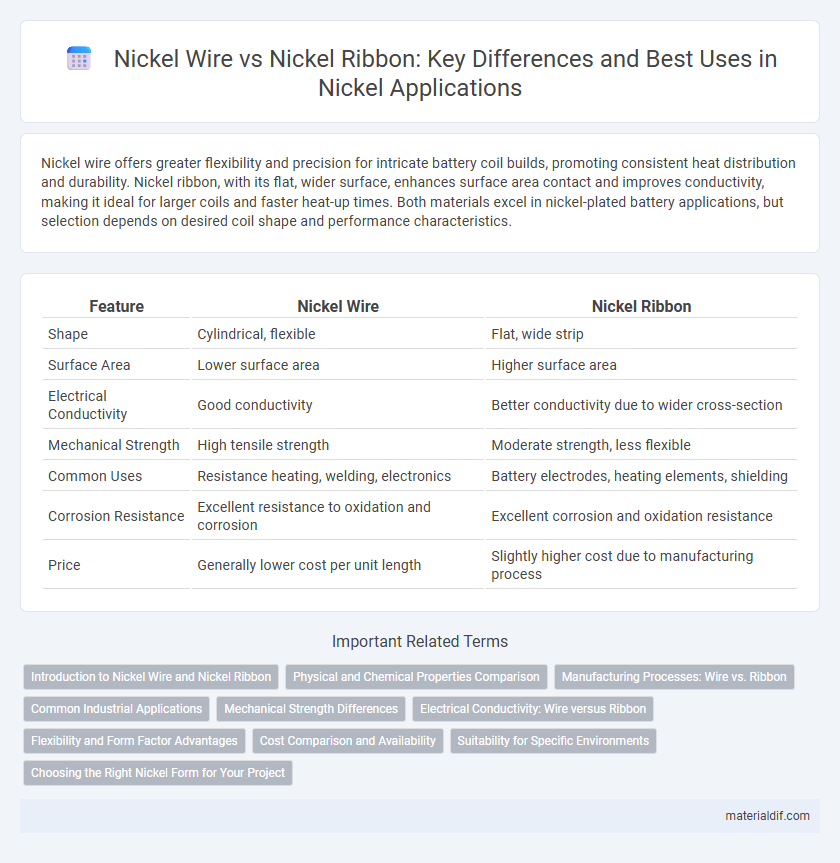

Nickel wire offers greater flexibility and precision for intricate battery coil builds, promoting consistent heat distribution and durability. Nickel ribbon, with its flat, wider surface, enhances surface area contact and improves conductivity, making it ideal for larger coils and faster heat-up times. Both materials excel in nickel-plated battery applications, but selection depends on desired coil shape and performance characteristics.

Table of Comparison

| Feature | Nickel Wire | Nickel Ribbon |

|---|---|---|

| Shape | Cylindrical, flexible | Flat, wide strip |

| Surface Area | Lower surface area | Higher surface area |

| Electrical Conductivity | Good conductivity | Better conductivity due to wider cross-section |

| Mechanical Strength | High tensile strength | Moderate strength, less flexible |

| Common Uses | Resistance heating, welding, electronics | Battery electrodes, heating elements, shielding |

| Corrosion Resistance | Excellent resistance to oxidation and corrosion | Excellent corrosion and oxidation resistance |

| Price | Generally lower cost per unit length | Slightly higher cost due to manufacturing process |

Introduction to Nickel Wire and Nickel Ribbon

Nickel wire is a thin, flexible metal strand commonly used in electrical heating elements, battery electrodes, and resistance coils due to its excellent conductivity and corrosion resistance. Nickel ribbon, on the other hand, is a flat, wider strip of nickel often utilized in applications requiring uniform surface contact, such as fuel cell electrodes and welding electrodes. Both forms offer high durability and oxidation resistance, but nickel wire provides greater flexibility while nickel ribbon delivers enhanced surface area and mechanical strength.

Physical and Chemical Properties Comparison

Nickel wire exhibits high tensile strength and excellent flexibility, making it ideal for applications requiring durability and precision bending, while nickel ribbon offers a larger surface area and flat geometry that enhances heat distribution and electrical conductivity. Both forms possess outstanding corrosion resistance, retain magnetic properties at elevated temperatures, and maintain chemical stability in oxidizing and reducing environments. The choice between nickel wire and ribbon depends on specific application demands, including mechanical stress tolerance and thermal management.

Manufacturing Processes: Wire vs. Ribbon

Nickel wire is typically produced through a series of hot rolling, drawing, and annealing processes that enhance tensile strength and flexibility, making it ideal for intricate applications. In contrast, nickel ribbon is manufactured by cold rolling or melt spinning techniques followed by controlled annealing to achieve uniform thickness and superior surface finish, suitable for battery electrodes and heating elements. The distinct manufacturing processes influence the mechanical properties and surface characteristics, tailoring each form for specific industrial uses.

Common Industrial Applications

Nickel wire is widely used in resistance heating elements, battery manufacturing, and electrical contacts due to its high conductivity and flexibility. Nickel ribbon, characterized by its flat, wide profile, is preferred in applications such as thermocouples, battery tabs, and welding strips where surface area and heat dissipation are critical. Both forms offer excellent corrosion resistance and high-temperature stability, making them suitable for aerospace, chemical processing, and electronics industries.

Mechanical Strength Differences

Nickel wire exhibits higher mechanical strength due to its uniform cross-sectional area and greater tensile properties, making it ideal for applications requiring durability and flexibility. In contrast, nickel ribbon offers lower tensile strength but improved surface area and heat dissipation, favoring uses where conductivity and thermal management are critical. The choice between nickel wire and ribbon depends on balancing mechanical robustness against application-specific electrical and thermal requirements.

Electrical Conductivity: Wire versus Ribbon

Nickel wire exhibits higher electrical conductivity than nickel ribbon due to its smaller cross-sectional area, which allows for more efficient current flow and reduced resistance. Nickel ribbon, while offering greater surface area for heat dissipation, generally shows lower conductivity because of its flattened shape and increased grain boundaries. These differences make nickel wire preferable in applications requiring superior electrical performance, whereas nickel ribbon suits tasks involving thermal management and structural flexibility.

Flexibility and Form Factor Advantages

Nickel wire offers superior flexibility, making it ideal for applications requiring frequent bending or intricate shapes without compromising conductivity. Nickel ribbon provides a flat, broader surface area ideal for uniform current distribution and lower resistance in high-temperature environments. Choosing between nickel wire and ribbon depends on the specific form factor needs, where wire excels in dynamic flexibility while ribbon optimizes stable, planar electrical connections.

Cost Comparison and Availability

Nickel wire generally costs less than nickel ribbon due to lower manufacturing complexity and thinner gauge requirements, making it more budget-friendly for high-volume applications. Nickel ribbons, produced through specialized rolling and annealing processes, tend to have higher costs but offer superior mechanical strength and conductivity. Availability-wise, nickel wire is more widely accessible across industrial suppliers, while nickel ribbon may require sourcing from niche manufacturers, impacting lead times and pricing flexibility.

Suitability for Specific Environments

Nickel wire offers superior flexibility and corrosion resistance, making it ideal for applications requiring intricate shaping and exposure to harsh chemical environments. Nickel ribbon provides enhanced surface area and excellent conductivity, which suits high-temperature environments and electrical heating elements. The choice between nickel wire and ribbon depends on the specific mechanical and environmental demands of the application.

Choosing the Right Nickel Form for Your Project

Nickel wire offers flexibility and ease of shaping, ideal for intricate projects requiring precise bends, while nickel ribbon provides a flat, stable surface suited for applications needing uniform conductivity and structural support. Selecting between nickel wire and ribbon depends on project specifications such as electrical resistance, mechanical strength, and thermal stability, with wire preferred for coiling and ribbon for flat contacts or heating elements. Consider factors like diameter, thickness, and corrosion resistance to optimize performance in electronics, battery manufacturing, or heating applications.

Nickel wire vs Nickel ribbon Infographic

materialdif.com

materialdif.com