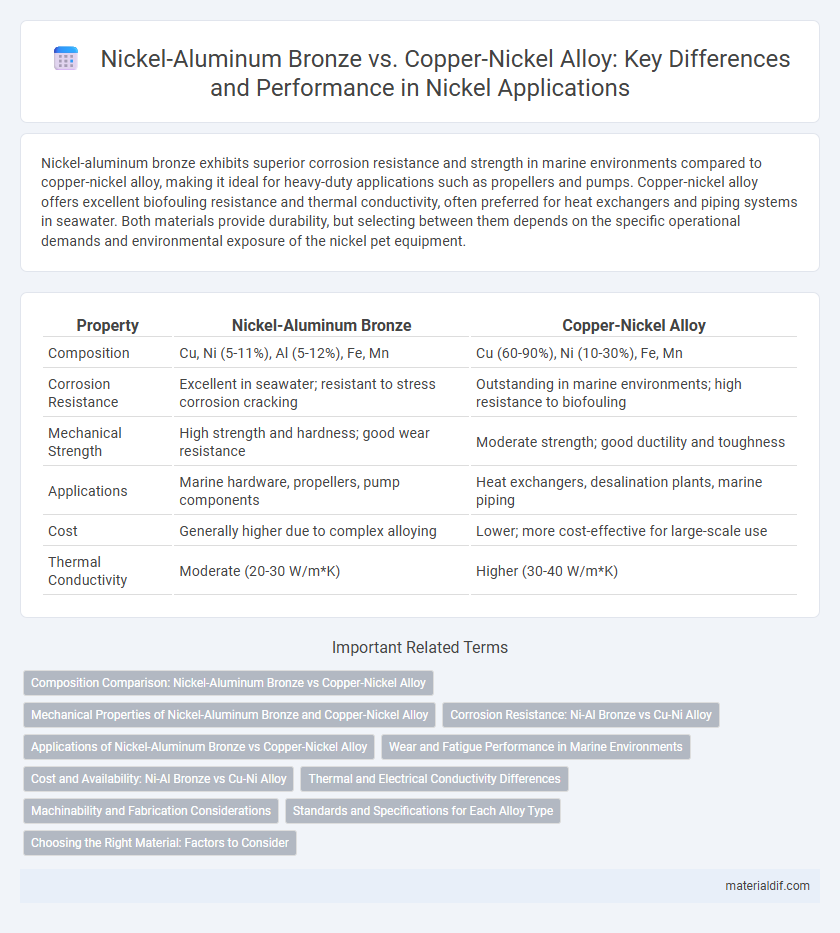

Nickel-aluminum bronze exhibits superior corrosion resistance and strength in marine environments compared to copper-nickel alloy, making it ideal for heavy-duty applications such as propellers and pumps. Copper-nickel alloy offers excellent biofouling resistance and thermal conductivity, often preferred for heat exchangers and piping systems in seawater. Both materials provide durability, but selecting between them depends on the specific operational demands and environmental exposure of the nickel pet equipment.

Table of Comparison

| Property | Nickel-Aluminum Bronze | Copper-Nickel Alloy |

|---|---|---|

| Composition | Cu, Ni (5-11%), Al (5-12%), Fe, Mn | Cu (60-90%), Ni (10-30%), Fe, Mn |

| Corrosion Resistance | Excellent in seawater; resistant to stress corrosion cracking | Outstanding in marine environments; high resistance to biofouling |

| Mechanical Strength | High strength and hardness; good wear resistance | Moderate strength; good ductility and toughness |

| Applications | Marine hardware, propellers, pump components | Heat exchangers, desalination plants, marine piping |

| Cost | Generally higher due to complex alloying | Lower; more cost-effective for large-scale use |

| Thermal Conductivity | Moderate (20-30 W/m*K) | Higher (30-40 W/m*K) |

Composition Comparison: Nickel-Aluminum Bronze vs Copper-Nickel Alloy

Nickel-aluminum bronze primarily contains 80-90% copper, 5-11% aluminum, 4-6% nickel, and smaller amounts of iron and manganese, offering excellent corrosion resistance and high strength. Copper-nickel alloy typically consists of 60-90% copper with 10-40% nickel, often including iron and manganese for enhanced durability and biofouling resistance. The higher aluminum content in nickel-aluminum bronze provides superior hardness and wear resistance, while the elevated nickel concentration in copper-nickel alloys enhances seawater corrosion resistance.

Mechanical Properties of Nickel-Aluminum Bronze and Copper-Nickel Alloy

Nickel-aluminum bronze exhibits high tensile strength and exceptional corrosion resistance, making it ideal for marine and industrial applications. Copper-nickel alloy offers superior ductility and resistance to biofouling, with moderate strength suited for piping and heat exchanger components. Both alloys provide excellent mechanical durability but nickel-aluminum bronze surpasses copper-nickel in load-bearing capacity and wear resistance.

Corrosion Resistance: Ni-Al Bronze vs Cu-Ni Alloy

Nickel-aluminum bronze exhibits superior corrosion resistance in marine environments due to its high strength and enhanced resistance to biofouling and dezincification compared to copper-nickel alloys. Copper-nickel alloys provide excellent resistance to seawater corrosion and erosion, particularly in turbulent water conditions, but can be more susceptible to stress corrosion cracking under certain conditions. Selecting between Ni-Al bronze and Cu-Ni alloy depends on specific environmental factors, including exposure to chlorides, temperature, and mechanical stress.

Applications of Nickel-Aluminum Bronze vs Copper-Nickel Alloy

Nickel-aluminum bronze is widely used in marine applications such as ship propellers, pump components, and seawater valves due to its excellent corrosion resistance, high strength, and resistance to biofouling. Copper-nickel alloy primarily finds applications in seawater piping, heat exchangers, and desalination plants where superior resistance to saltwater corrosion and biofouling are critical. Both alloys are essential in marine engineering, but nickel-aluminum bronze excels in mechanical strength and wear resistance, while copper-nickel is favored for its superior corrosion resistance in turbulent seawater environments.

Wear and Fatigue Performance in Marine Environments

Nickel-aluminum bronze exhibits superior wear resistance and fatigue strength in marine environments compared to copper-nickel alloys, making it ideal for high-load components like propellers and pumps. The alloy's unique microstructure enhances its ability to resist corrosion-induced pitting and erosion, which are critical factors in long-term durability under seawater exposure. Copper-nickel alloys offer good corrosion resistance but typically demonstrate lower fatigue life and wear performance when subjected to the dynamic stresses common in marine applications.

Cost and Availability: Ni-Al Bronze vs Cu-Ni Alloy

Nickel-aluminum bronze typically costs less than copper-nickel alloy due to its lower nickel content and more abundant raw materials. Copper-nickel alloys, often containing 10-30% nickel, have higher production costs and face supply constraints tied to fluctuating global nickel prices. Availability of nickel-aluminum bronze benefits from established manufacturing processes, while copper-nickel alloys can experience lead times influenced by nickel market demand and extraction rates.

Thermal and Electrical Conductivity Differences

Nickel-aluminum bronze exhibits lower thermal and electrical conductivity compared to copper-nickel alloys due to its complex microstructure and higher aluminum content, which disrupt electron flow. Copper-nickel alloys maintain better conductivity because of their simpler face-centered cubic structure and higher copper percentage, facilitating electron mobility. This difference makes copper-nickel preferable for applications requiring efficient heat dissipation and electrical conduction, while nickel-aluminum bronze is favored for strength and corrosion resistance in marine environments.

Machinability and Fabrication Considerations

Nickel-aluminum bronze exhibits superior machinability compared to copper-nickel alloys due to its unique microstructure and alloy composition, allowing for easier cutting and shaping with standard machining tools. Copper-nickel alloys, while offering excellent corrosion resistance, typically require specialized tooling and slower machining speeds to avoid work hardening and tool wear. Fabrication considerations also favor nickel-aluminum bronze for welding and casting processes due to its lower thermal conductivity and reduced risk of cracking.

Standards and Specifications for Each Alloy Type

Nickel-aluminum bronze alloys are primarily governed by ASTM B148 and B148M standards, emphasizing corrosion resistance and mechanical strength for marine and industrial applications. Copper-nickel alloys, standardized under ASTM B122 and B164, highlight superior resistance to seawater corrosion and biofouling, making them ideal for marine heat exchangers and piping systems. Each alloy type complies with specific ASTM specifications tailored to their unique compositions and performance requirements in demanding environments.

Choosing the Right Material: Factors to Consider

Choosing between Nickel-aluminum bronze and Copper-nickel alloy depends on factors such as corrosion resistance, mechanical strength, and application environment. Nickel-aluminum bronze offers superior resistance to seawater corrosion and high strength, making it ideal for marine and industrial components exposed to harsh environments. Copper-nickel alloys provide excellent resistance to biofouling and moderate corrosion, suitable for heat exchangers and piping in less aggressive conditions.

Nickel-aluminum bronze vs Copper-nickel alloy Infographic

materialdif.com

materialdif.com