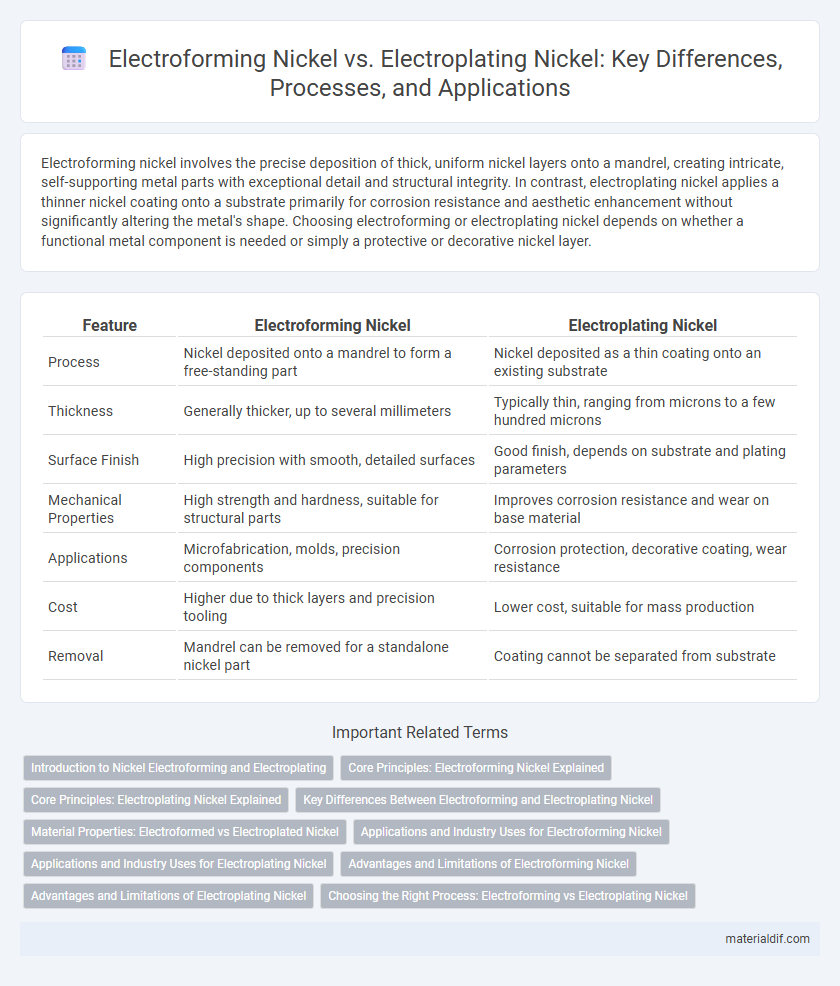

Electroforming nickel involves the precise deposition of thick, uniform nickel layers onto a mandrel, creating intricate, self-supporting metal parts with exceptional detail and structural integrity. In contrast, electroplating nickel applies a thinner nickel coating onto a substrate primarily for corrosion resistance and aesthetic enhancement without significantly altering the metal's shape. Choosing electroforming or electroplating nickel depends on whether a functional metal component is needed or simply a protective or decorative nickel layer.

Table of Comparison

| Feature | Electroforming Nickel | Electroplating Nickel |

|---|---|---|

| Process | Nickel deposited onto a mandrel to form a free-standing part | Nickel deposited as a thin coating onto an existing substrate |

| Thickness | Generally thicker, up to several millimeters | Typically thin, ranging from microns to a few hundred microns |

| Surface Finish | High precision with smooth, detailed surfaces | Good finish, depends on substrate and plating parameters |

| Mechanical Properties | High strength and hardness, suitable for structural parts | Improves corrosion resistance and wear on base material |

| Applications | Microfabrication, molds, precision components | Corrosion protection, decorative coating, wear resistance |

| Cost | Higher due to thick layers and precision tooling | Lower cost, suitable for mass production |

| Removal | Mandrel can be removed for a standalone nickel part | Coating cannot be separated from substrate |

Introduction to Nickel Electroforming and Electroplating

Nickel electroforming involves creating precise, thick metallic layers by depositing nickel onto a mold to form intricate shapes, widely used in aerospace and medical applications for its superior dimensional accuracy and durability. Electroplating nickel coats surfaces with a thin, protective layer to enhance corrosion resistance, wear resistance, and aesthetic appeal, commonly applied in electronics, automotive, and decorative industries. Both processes utilize nickel sulfate electrolytes, but electroforming focuses on building up freestanding structures while electroplating primarily improves surface properties.

Core Principles: Electroforming Nickel Explained

Electroforming nickel involves depositing a thick, precise nickel layer onto a mandrel through controlled electrochemical reduction, allowing the formation of complex, free-standing metal parts. Electroplating nickel primarily focuses on applying a thin, uniform nickel coating to enhance surface properties like corrosion resistance and aesthetics. The core principle of electroforming lies in building up substantial metal thickness by advanced layer-by-layer electrodeposition, enabling structural integrity and intricate design replication unattainable through standard electroplating techniques.

Core Principles: Electroplating Nickel Explained

Electroplating nickel involves depositing a thin, uniform layer of nickel onto a substrate through an electrolytic process, enhancing corrosion resistance and surface durability. The process relies on the reduction of nickel ions from a nickel salt solution onto the conductive object's surface, using an external electric current. Unlike electroforming, which builds thick, self-supporting metal parts, nickel electroplating focuses on coating existing components with precision and control over layer thickness.

Key Differences Between Electroforming and Electroplating Nickel

Electroforming nickel involves building up a thick, self-supporting layer of pure nickel on a mandrel, allowing intricate, precise shapes to be created and then separated as standalone objects. Electroplating nickel deposits a thinner nickel layer onto an existing substrate primarily for decorative, protective, or functional coating purposes without the need to remove the base. Key differences include electroforming's use for additive manufacturing of detailed parts versus electroplating's focus on enhancing surface properties with controlled thickness.

Material Properties: Electroformed vs Electroplated Nickel

Electroformed nickel exhibits superior mechanical strength and higher purity compared to electroplated nickel, resulting in enhanced durability and corrosion resistance. The dense, uniform microstructure of electroformed nickel contributes to better dimensional stability and reduced internal stress, making it ideal for precision components. Electroplated nickel, while more cost-effective, tends to have a less consistent deposit with potential porosity and lower hardness, affecting its performance in demanding applications.

Applications and Industry Uses for Electroforming Nickel

Electroforming nickel produces precise, intricate metal parts with high structural integrity, making it ideal for aerospace, electronics, and medical device industries requiring complex geometries and superior mechanical properties. This process enables the creation of lightweight, durable components such as micro-electromechanical systems (MEMS), precision molds, and detailed circuit boards. Compared to electroplating, electroforming nickel is favored in industries demanding high precision and customized thickness control for advanced manufacturing applications.

Applications and Industry Uses for Electroplating Nickel

Electroplating nickel is widely used in industries requiring corrosion resistance, wear protection, and aesthetic finishes, such as automotive, electronics, and aerospace sectors. It provides a uniform, thin coating that enhances surface hardness and electrical conductivity, making it ideal for decorative purposes and functional layers on connectors and circuit boards. This industry-preferred method supports mass production with cost-effective, precise coatings that improve durability and performance in consumer goods and industrial components.

Advantages and Limitations of Electroforming Nickel

Electroforming nickel offers superior thickness control and the ability to create complex, high-precision nickel parts compared to electroplating, making it ideal for intricate microfabrication and tooling applications. Its advantage lies in producing uniformly thick, stress-free deposits with excellent surface finish, enhancing durability and mechanical properties. However, electroforming requires longer processing times and higher costs, limiting its efficiency for large-scale or rapid production compared to traditional electroplating methods.

Advantages and Limitations of Electroplating Nickel

Electroplating nickel offers advantages such as improved corrosion resistance, enhanced wear protection, and cost-effectiveness for thin coatings compared to electroforming nickel, which is better suited for creating thick, high-precision metal layers. Limitations of electroplating nickel include less control over thickness uniformity and potential hydrogen embrittlement affecting mechanical properties, which can compromise performance in demanding industrial applications. Electroforming nickel requires longer processing times and higher energy consumption, but electroplating remains the preferred method for surface finishing in automotive and electronics industries due to faster production rates and lower material usage.

Choosing the Right Process: Electroforming vs Electroplating Nickel

Electroforming nickel involves depositing thick, fully dense nickel layers to create freestanding metal parts, ideal for high-precision molds and complex geometries. Electroplating nickel applies a thinner nickel coating for surface enhancement, corrosion resistance, and decorative finishes on existing substrates. Choosing the right process depends on the application requirements: electroforming is preferred for building up intricate metal components, while electroplating suits surface protection and aesthetic improvements.

Electroforming Nickel vs Electroplating Nickel Infographic

materialdif.com

materialdif.com