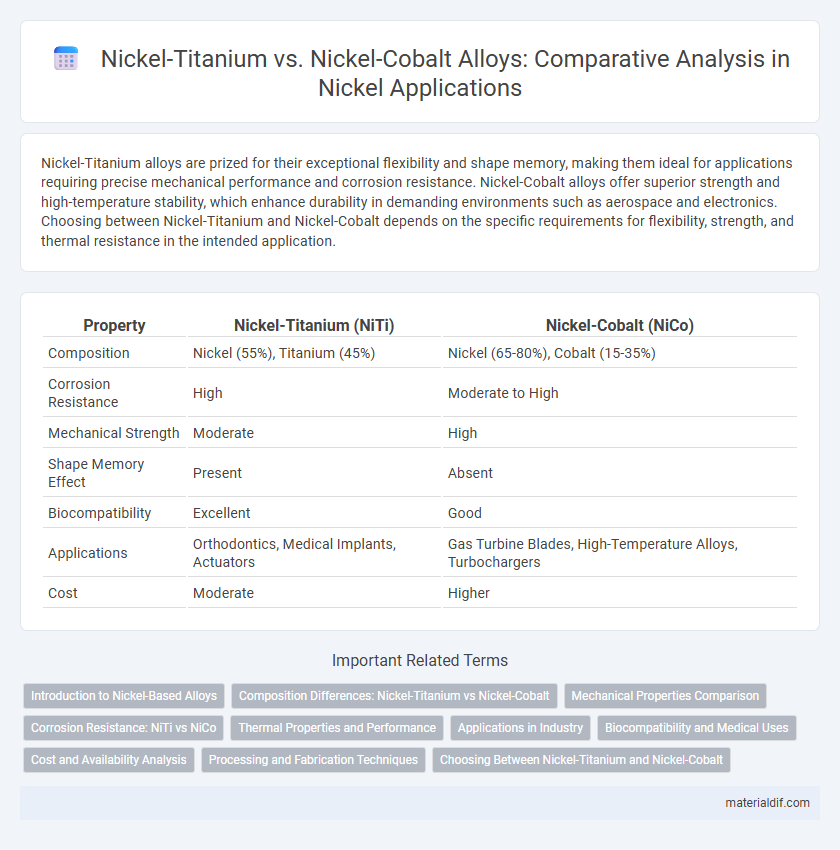

Nickel-Titanium alloys are prized for their exceptional flexibility and shape memory, making them ideal for applications requiring precise mechanical performance and corrosion resistance. Nickel-Cobalt alloys offer superior strength and high-temperature stability, which enhance durability in demanding environments such as aerospace and electronics. Choosing between Nickel-Titanium and Nickel-Cobalt depends on the specific requirements for flexibility, strength, and thermal resistance in the intended application.

Table of Comparison

| Property | Nickel-Titanium (NiTi) | Nickel-Cobalt (NiCo) |

|---|---|---|

| Composition | Nickel (55%), Titanium (45%) | Nickel (65-80%), Cobalt (15-35%) |

| Corrosion Resistance | High | Moderate to High |

| Mechanical Strength | Moderate | High |

| Shape Memory Effect | Present | Absent |

| Biocompatibility | Excellent | Good |

| Applications | Orthodontics, Medical Implants, Actuators | Gas Turbine Blades, High-Temperature Alloys, Turbochargers |

| Cost | Moderate | Higher |

Introduction to Nickel-Based Alloys

Nickel-based alloys such as Nickel-Titanium (NiTi) and Nickel-Cobalt (NiCo) exhibit unique properties tailored for diverse industrial applications, including aerospace and medical devices. NiTi alloys are renowned for their shape memory and superelasticity, making them ideal for use in medical stents and actuators. In contrast, NiCo alloys offer enhanced strength, magnetic properties, and corrosion resistance, which are critical for high-performance turbine blades and electronic components.

Composition Differences: Nickel-Titanium vs Nickel-Cobalt

Nickel-Titanium alloys primarily consist of approximately 55% nickel and 45% titanium, exhibiting exceptional shape memory and superelasticity due to this unique composition. In contrast, Nickel-Cobalt alloys combine nickel with varying amounts of cobalt, typically ranging from 10% to 40%, enhancing magnetic properties and corrosion resistance. The compositional variance between Nickel-Titanium and Nickel-Cobalt directly influences their mechanical behavior and application versatility in medical devices and aerospace industries.

Mechanical Properties Comparison

Nickel-Titanium (NiTi) alloys exhibit exceptional superelasticity and shape memory properties, making them ideal for applications requiring flexibility and fatigue resistance, such as medical devices and actuators. Nickel-Cobalt (NiCo) alloys demonstrate higher magnetic saturation and improved hardness, lending superior strength and wear resistance suitable for aerospace and industrial components. Mechanical property comparisons reveal NiTi's superior elasticity and corrosion resistance, while NiCo alloys offer enhanced tensile strength and thermal stability under extreme conditions.

Corrosion Resistance: NiTi vs NiCo

Nickel-Titanium (NiTi) alloys exhibit superior corrosion resistance due to the stable titanium oxide layer that forms on their surface, enhancing durability in harsh environments. Nickel-Cobalt (NiCo) alloys, while offering high strength and magnetic properties, generally display lower corrosion resistance compared to NiTi, as cobalt can accelerate localized corrosion under certain conditions. Studies indicate NiTi's corrosion rate is significantly lower in physiological and marine environments, making it the preferred choice for biomedical implants and marine applications.

Thermal Properties and Performance

Nickel-Titanium alloys exhibit exceptional shape memory and superelastic properties due to their unique phase transformation at specific temperatures, making them ideal for applications requiring thermal responsiveness and flexibility. Nickel-Cobalt alloys demonstrate higher thermal conductivity and enhanced mechanical strength at elevated temperatures, which improves performance in high-heat environments and corrosion resistance. The thermal stability of Nickel-Cobalt supports long-term durability, whereas Nickel-Titanium's thermal hysteresis enables precise control in thermomechanical systems.

Applications in Industry

Nickel-Titanium alloys, known as Nitinol, are widely used in medical devices such as stents and orthodontic wires due to their unique shape memory and superelastic properties. Nickel-Cobalt alloys excel in aerospace and energy sectors, offering superior magnetic performance and high strength at elevated temperatures. These distinct material characteristics define their targeted applications, with Nickel-Titanium favoring flexible, responsive uses and Nickel-Cobalt supporting structural and magnetic demands.

Biocompatibility and Medical Uses

Nickel-Titanium alloys exhibit superior biocompatibility due to their excellent corrosion resistance and shape memory properties, making them ideal for medical implants such as stents and orthodontic wires. In contrast, Nickel-Cobalt alloys, although strong and wear-resistant, pose higher risks of metal ion release and allergic reactions, limiting their use in direct contact with biological tissues. Medical applications favor Nickel-Titanium for long-term implantation where reduced cytotoxicity and enhanced flexibility are critical.

Cost and Availability Analysis

Nickel-Titanium alloys generally offer lower cost due to the abundance of titanium and more established production methods compared to Nickel-Cobalt alloys, which are more expensive because cobalt is a rarer and costlier metal. Availability of Nickel-Titanium is higher as titanium is widely sourced from multiple global deposits, whereas cobalt supply is geographically concentrated, primarily in the Democratic Republic of Congo, leading to supply chain vulnerabilities. Cost-sensitive industries often prefer Nickel-Titanium for its balance of performance and affordability, while Nickel-Cobalt is favored in applications requiring enhanced corrosion resistance and magnetic properties despite higher material expenses.

Processing and Fabrication Techniques

Nickel-Titanium alloys are primarily processed using shape memory and superelasticity techniques involving thermomechanical treatments such as cold working followed by precise heat treatments to achieve desired phase transformations. Nickel-Cobalt alloys typically undergo powder metallurgy and casting methods, optimizing cobalt content to enhance mechanical strength and corrosion resistance during fabrication. Advanced additive manufacturing is increasingly applied to both alloys, enabling complex geometries while maintaining their unique metallurgical properties.

Choosing Between Nickel-Titanium and Nickel-Cobalt

Choosing between Nickel-Titanium and Nickel-Cobalt alloys depends on specific application requirements such as corrosion resistance, mechanical strength, and thermal stability. Nickel-Titanium offers superior shape memory and flexibility, making it ideal for aerospace and medical devices, while Nickel-Cobalt provides enhanced hardness and higher resistance to wear, commonly used in high-performance batteries and superalloys. Evaluating the operational environment and material performance criteria ensures the optimal alloy selection for durability and functionality.

Nickel-Titanium vs Nickel-Cobalt Infographic

materialdif.com

materialdif.com