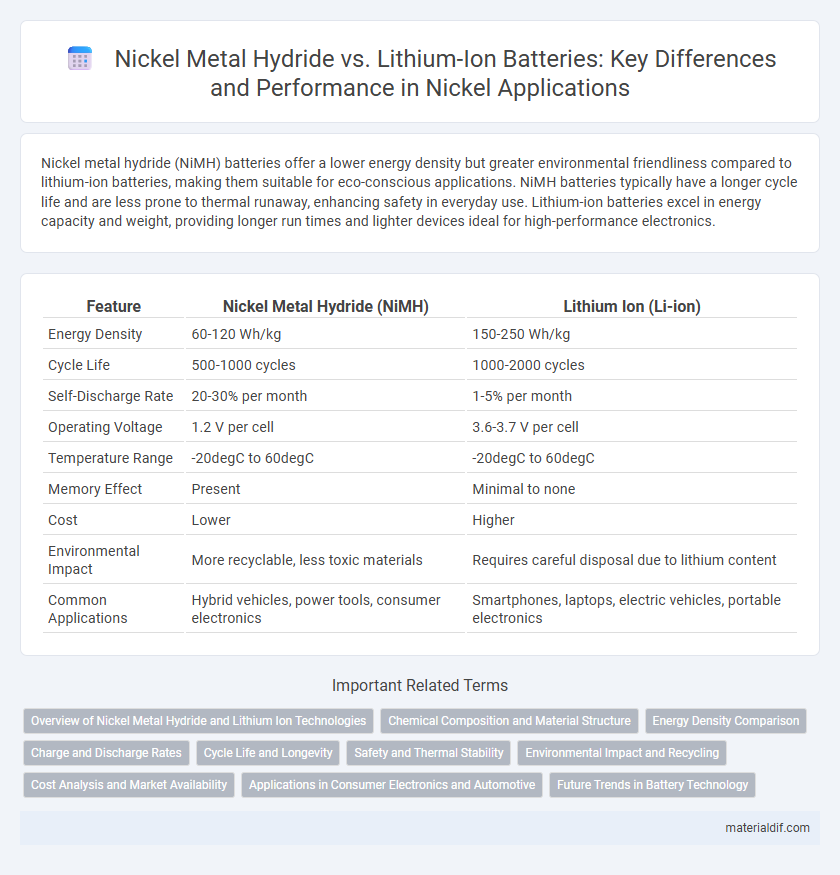

Nickel metal hydride (NiMH) batteries offer a lower energy density but greater environmental friendliness compared to lithium-ion batteries, making them suitable for eco-conscious applications. NiMH batteries typically have a longer cycle life and are less prone to thermal runaway, enhancing safety in everyday use. Lithium-ion batteries excel in energy capacity and weight, providing longer run times and lighter devices ideal for high-performance electronics.

Table of Comparison

| Feature | Nickel Metal Hydride (NiMH) | Lithium Ion (Li-ion) |

|---|---|---|

| Energy Density | 60-120 Wh/kg | 150-250 Wh/kg |

| Cycle Life | 500-1000 cycles | 1000-2000 cycles |

| Self-Discharge Rate | 20-30% per month | 1-5% per month |

| Operating Voltage | 1.2 V per cell | 3.6-3.7 V per cell |

| Temperature Range | -20degC to 60degC | -20degC to 60degC |

| Memory Effect | Present | Minimal to none |

| Cost | Lower | Higher |

| Environmental Impact | More recyclable, less toxic materials | Requires careful disposal due to lithium content |

| Common Applications | Hybrid vehicles, power tools, consumer electronics | Smartphones, laptops, electric vehicles, portable electronics |

Overview of Nickel Metal Hydride and Lithium Ion Technologies

Nickel Metal Hydride (NiMH) batteries feature a positive nickel oxyhydroxide electrode and a negative hydrogen-absorbing alloy, offering high energy density and superior safety compared to early rechargeable technologies. Lithium Ion (Li-ion) batteries utilize lithium compounds for the cathode and graphitic carbon for the anode, providing higher energy density, longer cycle life, and faster charging capabilities. NiMH remains prevalent in hybrid vehicles and consumer electronics due to cost-effectiveness and environmental benefits, while Li-ion dominates portable electronics and electric vehicles for its lightweight and performance advantages.

Chemical Composition and Material Structure

Nickel metal hydride (NiMH) batteries feature a metal alloy hydride as the negative electrode, utilizing hydrogen atoms absorbed in the metal lattice, whereas lithium-ion batteries rely on lithium cobalt oxide or lithium iron phosphate cathodes combined with graphite or silicon-based anodes. The chemical composition of NiMH cells includes nickel hydroxide as the positive electrode and a metal hydride alloy capable of reversible hydrogen storage, which affects charge density and cycle life. Material structures in NiMH promote higher tolerance to overcharging and thermal stability, while lithium-ion materials offer higher energy density but require more complex management systems due to reactive lithium compounds.

Energy Density Comparison

Nickel Metal Hydride (NiMH) batteries typically exhibit an energy density ranging from 60 to 120 Wh/kg, which is significantly lower than Lithium-Ion (Li-ion) batteries that offer energy densities between 150 and 250 Wh/kg. This higher energy density of Li-ion cells translates to longer battery life and improved performance in portable electronics and electric vehicles. Despite NiMH's advantages in thermal stability and cost, Li-ion's superior energy density remains a critical factor driving its dominance in high-demand applications.

Charge and Discharge Rates

Nickel metal hydride (NiMH) batteries typically exhibit lower charge and discharge rates compared to lithium ion (Li-ion) batteries, with NiMH charging efficiently at around 0.5C to 1C and discharging at similar or slightly higher rates. Lithium ion batteries support faster charging, often exceeding 2C rates, and enable higher discharge currents, making them suitable for high-performance applications requiring rapid energy delivery. The electrochemical properties of Li-ion cells allow superior rate capabilities, enhanced cycle life, and better energy density compared to NiMH counterparts.

Cycle Life and Longevity

Nickel metal hydride (NiMH) batteries typically offer a cycle life ranging from 500 to 1,000 cycles, making them suitable for moderate use applications, while lithium-ion batteries often exceed 1,000 cycles, with some models reaching up to 3,000 cycles under optimal conditions. The longevity of NiMH batteries is affected by memory effect and capacity degradation over time, whereas lithium-ion batteries benefit from improved energy density and better retention of capacity during repeated charge-discharge cycles. Temperature stability and low self-discharge rates in lithium-ion cells contribute to their superior lifespan and reliability for high-demand applications.

Safety and Thermal Stability

Nickel metal hydride (NiMH) batteries exhibit superior thermal stability compared to lithium-ion batteries, reducing the risk of thermal runaway and related safety hazards. NiMH cells operate at lower voltages and generate less heat during charge and discharge cycles, enhancing overall safety in consumer and industrial applications. Lithium-ion batteries, while offering higher energy density, require advanced thermal management systems to prevent overheating and potential fire risks.

Environmental Impact and Recycling

Nickel metal hydride (NiMH) batteries have a lower environmental impact during production compared to lithium-ion batteries due to less reliance on cobalt and rare earth metals, reducing mining-related ecological damage. NiMH batteries are easier to recycle with established processes that recover nickel and rare earth elements efficiently, while lithium-ion recycling remains more complex and less widespread, often recovering fewer valuable materials. The higher energy density of lithium-ion batteries offers performance advantages but comes with increased environmental costs tied to raw material extraction and current recycling challenges.

Cost Analysis and Market Availability

Nickel metal hydride (NiMH) batteries generally offer a lower initial cost compared to lithium-ion batteries, making them an economical choice for mid-range applications. NiMH batteries benefit from established manufacturing infrastructure and abundant raw materials, enhancing market availability particularly in automotive sectors like hybrid vehicles. Lithium-ion batteries, despite higher costs, dominate the market due to superior energy density and longer cycle life, but their price continues to decrease as production scales and supply chains improve.

Applications in Consumer Electronics and Automotive

Nickel metal hydride (NiMH) batteries offer higher durability and safer thermal stability, making them suitable for hybrid automotive applications requiring robust cycle life and reliable performance under variable temperatures. Lithium-ion batteries dominate consumer electronics due to their higher energy density, enabling longer usage times in smartphones, laptops, and tablets where lightweight and compact size are critical. In electric vehicles, lithium-ion technology supports greater driving range and faster charging capabilities compared to NiMH, driving its preference in fully electric automotive designs.

Future Trends in Battery Technology

Nickel metal hydride (NiMH) batteries offer reliable performance and superior thermal stability, making them a preferred choice for hybrid vehicles, but lithium-ion batteries dominate future trends due to higher energy density and longer cycle life. Advances in lithium-ion chemistry, such as nickel-rich cathodes, enhance capacity and reduce reliance on cobalt, positioning nickel as a critical element in next-generation energy storage. Ongoing research focuses on optimizing nickel-based materials to improve battery safety, charging speed, and sustainability, driving innovation in electric vehicles and renewable energy applications.

Nickel metal hydride vs lithium ion Infographic

materialdif.com

materialdif.com