Thermal spraying for nickel coatings involves melting nickel particles before propelling them onto a substrate, resulting in a dense, well-adhered layer but potentially causing oxidation and thermal distortion. Cold spraying deposits nickel particles at high velocities without melting, preserving the metal's microstructure and offering superior corrosion resistance with minimal thermal effects. Choosing between thermal and cold spraying depends on the application requirements for coating density, adhesion, and thermal sensitivity.

Table of Comparison

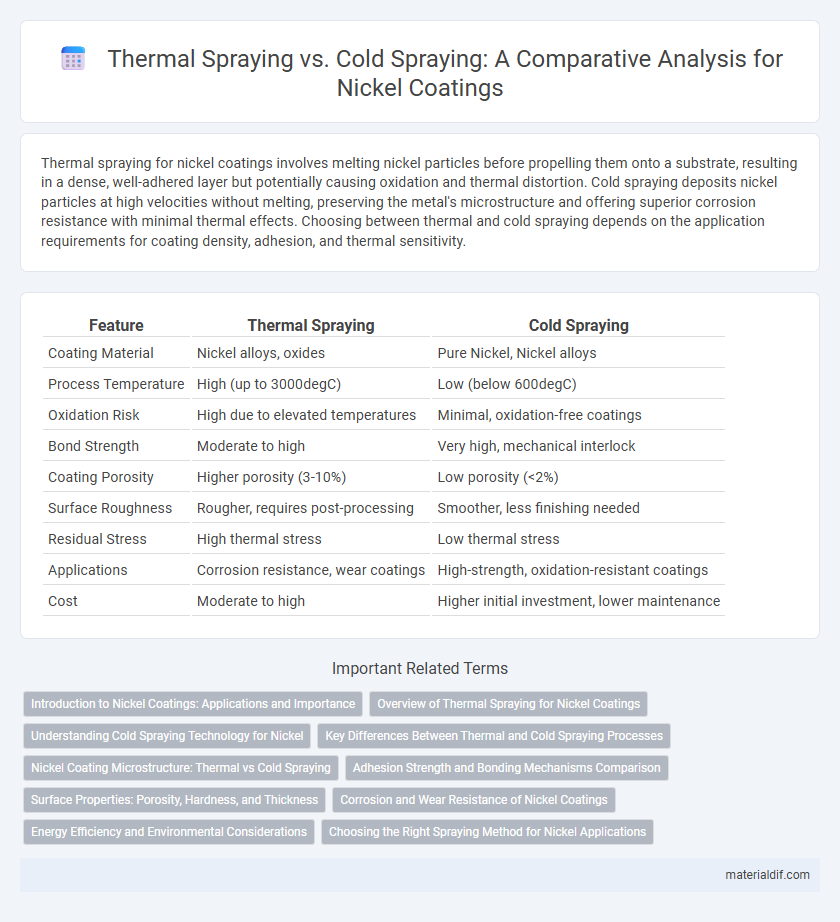

| Feature | Thermal Spraying | Cold Spraying |

|---|---|---|

| Coating Material | Nickel alloys, oxides | Pure Nickel, Nickel alloys |

| Process Temperature | High (up to 3000degC) | Low (below 600degC) |

| Oxidation Risk | High due to elevated temperatures | Minimal, oxidation-free coatings |

| Bond Strength | Moderate to high | Very high, mechanical interlock |

| Coating Porosity | Higher porosity (3-10%) | Low porosity (<2%) |

| Surface Roughness | Rougher, requires post-processing | Smoother, less finishing needed |

| Residual Stress | High thermal stress | Low thermal stress |

| Applications | Corrosion resistance, wear coatings | High-strength, oxidation-resistant coatings |

| Cost | Moderate to high | Higher initial investment, lower maintenance |

Introduction to Nickel Coatings: Applications and Importance

Nickel coatings provide exceptional corrosion resistance and wear protection, making them critical in aerospace, automotive, and chemical processing industries. Thermal spraying deposits molten nickel particles onto surfaces, creating dense, adherent coatings ideal for high-temperature environments. Cold spraying, a low-heat process, retains nickel's microstructure and properties while offering improved coating porosity and bonding strength for sensitive substrates.

Overview of Thermal Spraying for Nickel Coatings

Thermal spraying for nickel coatings involves the application of molten or semi-molten nickel particles onto a substrate, creating a dense, corrosion-resistant layer that enhances surface properties such as wear resistance and thermal conductivity. This process supports various feedstock forms, including powders and wires, and achieves coating thicknesses ranging from microns to millimeters, tailored to industrial needs. Thermal spraying techniques like plasma spraying and high-velocity oxy-fuel (HVOF) provide strong metallurgical bonding and uniform coatings, which are critical for applications in aerospace, automotive, and chemical processing industries.

Understanding Cold Spraying Technology for Nickel

Cold spraying technology for nickel coatings involves propelling nickel particles at supersonic speeds onto substrates without melting, preserving the material's original properties and minimizing oxidation. This process results in dense, high-purity nickel coatings with excellent adhesion and corrosion resistance, making it ideal for applications requiring surface protection and wear resistance. Compared to thermal spraying, cold spraying reduces thermal stresses and thermal distortion, ensuring superior coating integrity and performance in demanding environments.

Key Differences Between Thermal and Cold Spraying Processes

Thermal spraying for nickel coatings involves melting the feedstock material to create a high-temperature spray that adheres to surfaces, resulting in dense and well-bonded layers with excellent corrosion resistance. Cold spraying, in contrast, propels solid nickel particles at supersonic speeds without melting, producing coatings with superior mechanical properties and minimal oxidation. The key differences lie in thermal impact on the substrate, coating porosity, and oxidation levels, with thermal spraying generating higher temperatures and potential oxidation, while cold spraying offers lower thermal input and cleaner, more ductile coatings.

Nickel Coating Microstructure: Thermal vs Cold Spraying

Nickel coatings produced by thermal spraying exhibit a heterogeneous microstructure characterized by rapid solidification, resulting in significant oxide inclusions and porosity that can affect corrosion resistance and mechanical properties. Cold spraying of nickel yields a dense, oxide-free microstructure with superior cohesion due to solid-state particle deposition, enhancing wear resistance and minimizing thermal degradation. The microstructural differences between thermal and cold sprayed nickel coatings critically influence their performance in high-temperature and corrosive environments.

Adhesion Strength and Bonding Mechanisms Comparison

Thermal spraying of nickel coatings achieves adhesion strength through the formation of mechanical interlocking and metallurgical bonding due to high-temperature particle melting and substrate surface activation. In contrast, cold spraying preserves the original powder microstructure, relying on solid-state plastic deformation and high-velocity particle impact to produce strong adhesion without oxidation or thermal degradation. Cold spraying typically offers superior bond strength and coating density for nickel, enhancing corrosion resistance and wear performance compared to thermal spraying.

Surface Properties: Porosity, Hardness, and Thickness

Nickel coatings applied via thermal spraying typically exhibit higher porosity levels ranging from 5% to 15%, which can reduce corrosion resistance, whereas cold spraying produces denser deposits with porosity below 1%, enhancing surface integrity. Hardness values for thermally sprayed nickel coatings often measure between 300 to 400 HV due to oxidation and rapid solidification effects, while cold sprayed nickel can achieve hardness exceeding 450 HV owing to severe plastic deformation and refined microstructure. Thickness of thermal sprayed coatings generally varies from 100 to 500 microns, allowing for versatile layer build-up, whereas cold sprayed nickel layers tend to be thinner, around 50 to 300 microns, but with superior adhesion and minimal oxidation.

Corrosion and Wear Resistance of Nickel Coatings

Nickel coatings applied through thermal spraying exhibit high hardness and wear resistance but may suffer from oxidation and porosity, leading to reduced corrosion protection. Cold spraying deposits nickel particles in a solid state, producing dense, oxide-free coatings with superior corrosion resistance and enhanced adhesion, improving wear performance in aggressive environments. The choice between these methods depends on the required balance of surface hardness and long-term corrosion protection for specific industrial applications.

Energy Efficiency and Environmental Considerations

Thermal spraying of nickel coatings involves high-temperature processes that consume significant energy and release emissions, impacting environmental sustainability. Cold spraying operates at lower temperatures, reducing energy consumption and minimizing oxidation, resulting in environmentally friendly nickel coatings. This energy efficiency and reduced environmental footprint make cold spraying a preferred method for nickel applications requiring sustainability.

Choosing the Right Spraying Method for Nickel Applications

Thermal spraying offers high deposition rates and strong metallurgical bonding for nickel coatings, making it ideal for applications requiring thick, durable layers. Cold spraying minimizes oxidation and thermal distortion, preserving nickel's microstructure and mechanical properties, which benefits precision components and corrosion-resistant surfaces. Selecting the appropriate spraying method depends on the required coating thickness, substrate sensitivity, and desired mechanical performance for nickel applications.

Thermal Spraying vs Cold Spraying (for Nickel coatings) Infographic

materialdif.com

materialdif.com