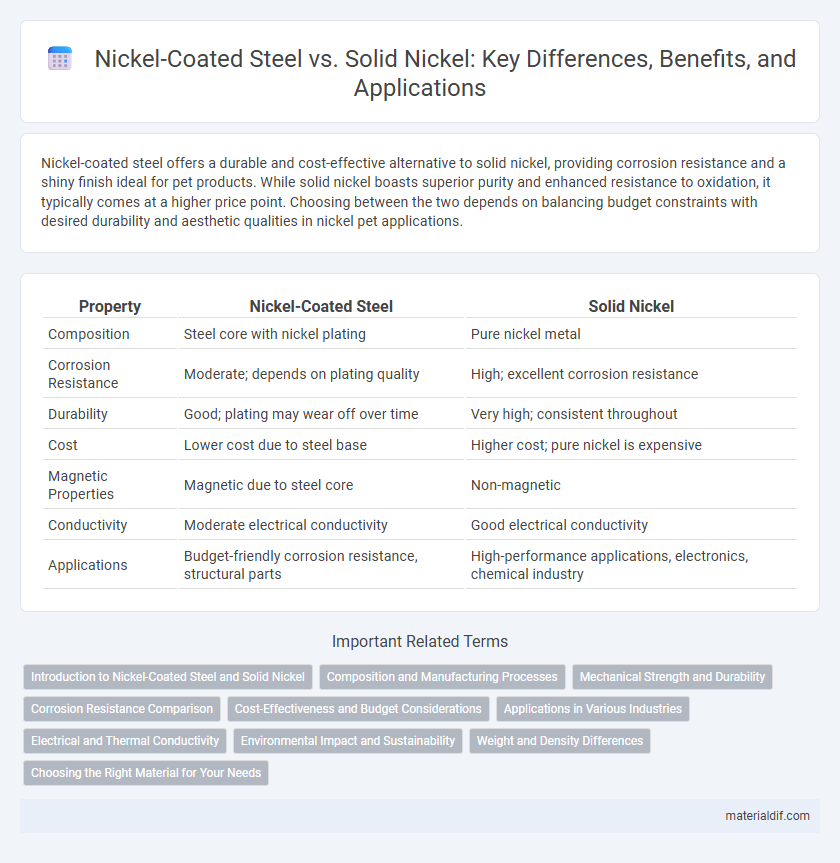

Nickel-coated steel offers a durable and cost-effective alternative to solid nickel, providing corrosion resistance and a shiny finish ideal for pet products. While solid nickel boasts superior purity and enhanced resistance to oxidation, it typically comes at a higher price point. Choosing between the two depends on balancing budget constraints with desired durability and aesthetic qualities in nickel pet applications.

Table of Comparison

| Property | Nickel-Coated Steel | Solid Nickel |

|---|---|---|

| Composition | Steel core with nickel plating | Pure nickel metal |

| Corrosion Resistance | Moderate; depends on plating quality | High; excellent corrosion resistance |

| Durability | Good; plating may wear off over time | Very high; consistent throughout |

| Cost | Lower cost due to steel base | Higher cost; pure nickel is expensive |

| Magnetic Properties | Magnetic due to steel core | Non-magnetic |

| Conductivity | Moderate electrical conductivity | Good electrical conductivity |

| Applications | Budget-friendly corrosion resistance, structural parts | High-performance applications, electronics, chemical industry |

Introduction to Nickel-Coated Steel and Solid Nickel

Nickel-coated steel combines a steel core with a thin layer of nickel to enhance corrosion resistance and surface durability while reducing material costs compared to solid nickel. Solid nickel, composed entirely of nickel, offers superior corrosion resistance, high thermal conductivity, and excellent electrical properties, making it suitable for demanding industrial applications. The choice between nickel-coated steel and solid nickel depends on performance requirements, budget constraints, and environmental exposure.

Composition and Manufacturing Processes

Nickel-coated steel features a carbon steel core with a thin layer of nickel applied through electroplating or electroless plating, enhancing corrosion resistance and surface hardness at a lower cost compared to solid nickel. Solid nickel consists of nearly pure nickel, typically over 99% nickel content, produced through processes such as melting, casting, and rolling, resulting in superior mechanical properties and corrosion resistance. Manufacturing nickel-coated steel involves combining base steel with nickel coating for economic efficiency, whereas solid nickel requires extensive refining and forming to achieve homogenous, high-purity nickel components.

Mechanical Strength and Durability

Nickel-coated steel combines the high tensile strength of steel with corrosion resistance from the nickel layer, resulting in enhanced mechanical strength and long-lasting durability under stress. Solid nickel offers excellent ductility and corrosion resistance but generally has lower tensile strength compared to nickel-coated steel. In applications requiring optimal mechanical performance and wear resistance, nickel-coated steel provides a more durable solution than solid nickel.

Corrosion Resistance Comparison

Nickel-coated steel offers enhanced corrosion resistance compared to uncoated steel due to its protective nickel layer that prevents oxidation and rust formation. Solid nickel, composed entirely of nickel, provides superior corrosion resistance in highly aggressive environments, including exposure to acids and saltwater, outperforming nickel-coated steel in durability. The choice between nickel-coated steel and solid nickel depends on the specific application requirements and the level of corrosion protection needed.

Cost-Effectiveness and Budget Considerations

Nickel-coated steel offers significant cost savings compared to solid nickel due to its lower material expenses and effective performance in corrosion resistance applications. Budget-conscious projects benefit from nickel-coated steel's balance of durability and affordability, making it ideal for large-scale manufacturing without compromising quality. Solid nickel remains preferable for high-corrosion environments but often incurs higher upfront and lifecycle costs impacting overall budget allocation.

Applications in Various Industries

Nickel-coated steel offers enhanced corrosion resistance and magnetic properties, making it ideal for automotive parts, electrical components, and household appliances. Solid nickel provides superior corrosion resistance and high-temperature stability, which is critical in chemical processing equipment, aerospace components, and marine environments. Both materials serve essential roles, with nickel-coated steel favored for cost-effective, durable solutions and solid nickel preferred for extreme conditions requiring maximum performance.

Electrical and Thermal Conductivity

Nickel-coated steel offers improved corrosion resistance but has lower electrical and thermal conductivity compared to solid nickel due to the steel core's properties. Solid nickel provides superior conductivity, making it ideal for applications requiring efficient electrical and heat transfer. The thickness of the nickel coating directly impacts the conductivity performance of nickel-coated steel in electrical and thermal uses.

Environmental Impact and Sustainability

Nickel-coated steel offers a lower environmental footprint compared to solid nickel due to reduced nickel content, leading to less intensive mining and resource extraction. The steel core in nickel-coated products enhances recyclability, as both steel and nickel layers can be separated and reused effectively. Solid nickel production demands higher energy consumption and generates more waste, making nickel-coated steel a more sustainable choice for industrial applications.

Weight and Density Differences

Nickel-coated steel combines the high strength and lower weight of steel with a thin layer of nickel, resulting in a material that is lighter than solid nickel yet resistant to corrosion. Solid nickel has a density of approximately 8.9 g/cm3, whereas nickel-coated steel benefits from steel's lower density of around 7.85 g/cm3, reducing overall weight without sacrificing durability. This difference in weight and density makes nickel-coated steel a preferred choice in applications demanding both strength and lighter materials.

Choosing the Right Material for Your Needs

Nickel-coated steel combines the strength and cost-effectiveness of steel with corrosion resistance, making it ideal for applications requiring durability and affordability. Solid nickel offers superior corrosion resistance and electrical conductivity, suitable for high-performance environments such as aerospace and electronics. Selecting between nickel-coated steel and solid nickel depends on factors like budget, corrosion exposure, mechanical stress, and specific application requirements.

Nickel-Coated Steel vs Solid Nickel Infographic

materialdif.com

materialdif.com