Type 200 nickel offers higher purity and excellent corrosion resistance, making it suitable for chemical and food processing industries. Type 201 nickel contains more manganese and iron, providing increased strength but reduced ductility compared to Type 200. Choosing between Type 200 and Type 201 depends on the specific application requirements, balancing corrosion resistance and mechanical strength.

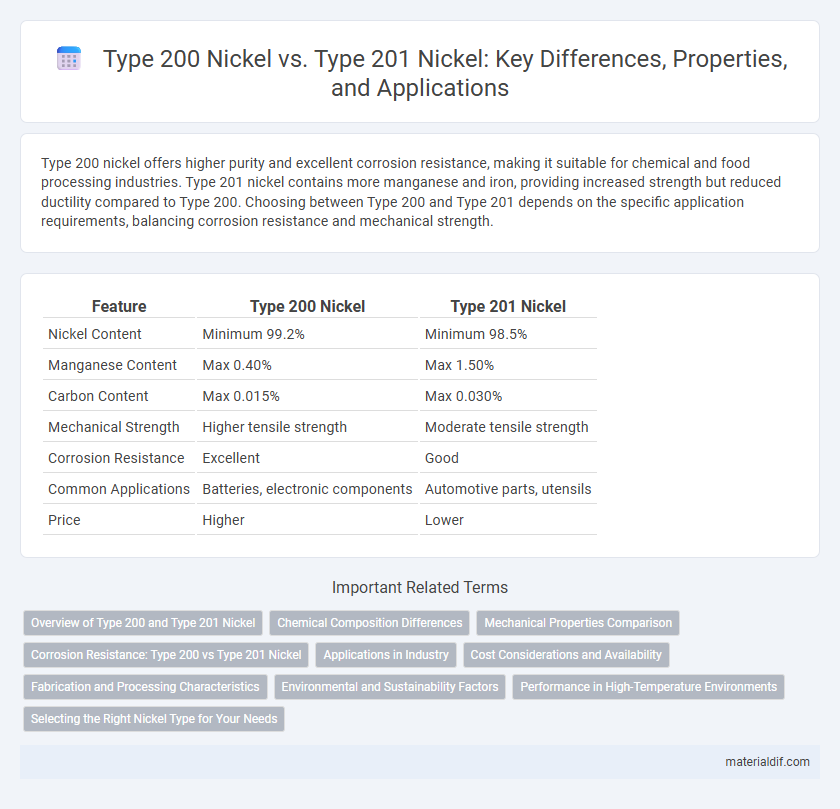

Table of Comparison

| Feature | Type 200 Nickel | Type 201 Nickel |

|---|---|---|

| Nickel Content | Minimum 99.2% | Minimum 98.5% |

| Manganese Content | Max 0.40% | Max 1.50% |

| Carbon Content | Max 0.015% | Max 0.030% |

| Mechanical Strength | Higher tensile strength | Moderate tensile strength |

| Corrosion Resistance | Excellent | Good |

| Common Applications | Batteries, electronic components | Automotive parts, utensils |

| Price | Higher | Lower |

Overview of Type 200 and Type 201 Nickel

Type 200 nickel, commonly referred to as nickel alloy 200, boasts high purity with a minimum of 99.0% nickel content, offering excellent corrosion resistance and high thermal conductivity suitable for chemical and food processing applications. Type 201 nickel contains increased manganese (5.5-7.0%) and decreased nickel content (balancing around 15-17%) to provide greater strength and resistance to stress corrosion cracking, making it ideal for structural and household applications. Both types differ mainly in their composition and mechanical properties, influencing their use across industries requiring specific corrosion resistance and strength characteristics.

Chemical Composition Differences

Type 200 nickel contains approximately 99.2% nickel with minimal manganese and iron, while Type 201 nickel has a lower nickel content of about 97.5% and a higher manganese level, typically around 4.7%, to reduce costs. The increased manganese in Type 201 alters its mechanical and corrosion-resistant properties compared to the purer Type 200. These chemical composition variations influence performance in applications requiring specific durability and resistance to environmental factors.

Mechanical Properties Comparison

Type 200 nickel exhibits higher tensile strength and better ductility compared to Type 201 nickel, making it more suitable for applications requiring enhanced mechanical durability. Type 200 typically displays a tensile strength around 570 MPa, whereas Type 201 ranges from 485 to 540 MPa, reflecting its slightly lower performance under stress. Elongation percentages also favor Type 200, reaching up to 40%, while Type 201 usually shows elongation around 25-35%, affecting flexibility in various industrial uses.

Corrosion Resistance: Type 200 vs Type 201 Nickel

Type 200 nickel exhibits superior corrosion resistance compared to Type 201 nickel due to its higher nickel content, typically around 63% versus 55% in Type 201. The increased nickel concentration in Type 200 enhances its resistance to acids, alkalis, and chloride environments, making it more suitable for harsh chemical applications. Type 201 nickel, with lower corrosion resistance, is generally preferred in less aggressive environments or where cost savings are prioritized.

Applications in Industry

Type 200 Nickel, known for its higher corrosion resistance and ductility, is widely used in chemical processing equipment, heat exchangers, and food processing machinery. Type 201 Nickel, featuring lower nickel content but increased strength, is often favored in automotive and architectural applications where cost efficiency and hardness are critical. Industrial sectors select Type 200 for environments requiring superior corrosion resistance, while Type 201 is chosen for structural applications demanding durability and economical material properties.

Cost Considerations and Availability

Type 201 nickel typically offers a lower cost alternative to Type 200 nickel due to its reduced nickel content and increased manganese levels, making it more budget-friendly for large-scale applications. Availability of Type 201 nickel is generally higher, especially in markets where cost sensitivity drives demand, whereas Type 200 nickel, with higher nickel content, may face supply constraints and price volatility linked to fluctuating nickel prices. Cost considerations favor Type 201 nickel for projects prioritizing affordability without significant compromise on corrosion resistance and mechanical properties.

Fabrication and Processing Characteristics

Type 200 Nickel features higher manganese content compared to Type 201, enhancing its ductility and making it easier to form into complex shapes during fabrication. In contrast, Type 201's lower nickel and higher manganese reduce material cost but can lead to increased work-hardening, requiring more careful control during cold working processes. Both types respond well to standard fabrication techniques such as welding, but Type 200 offers superior corrosion resistance, allowing for broader application in harsh environments.

Environmental and Sustainability Factors

Type 200 Nickel contains a higher nickel content, making it more corrosion-resistant and durable in harsh environments, which contributes to longer service life and less frequent replacements, reducing environmental waste. Type 201 Nickel uses less nickel and more manganese, resulting in a lower carbon footprint during production due to reduced nickel extraction impacts. From a sustainability perspective, Type 201 offers cost-effective environmental benefits through resource conservation, while Type 200 provides extended lifecycle advantages that minimize material consumption and waste generation.

Performance in High-Temperature Environments

Type 200 nickel exhibits superior resistance to high-temperature oxidation and maintains mechanical strength better than Type 201 nickel, making it ideal for applications involving prolonged exposure to elevated temperatures. The lower manganese content in Type 200 enhances its thermal stability, whereas Type 201's higher manganese levels can lead to reduced performance and increased susceptibility to embrittlement under high heat. These differences make Type 200 nickel preferable in industrial furnaces and heat exchangers operating above 600degC.

Selecting the Right Nickel Type for Your Needs

Type 200 Nickel offers higher corrosion resistance and better ductility, making it ideal for chemical processing and marine applications, whereas Type 201 Nickel provides enhanced strength and cost-efficiency, suitable for structural and automotive uses. Selection depends on balancing factors such as environmental exposure, mechanical requirements, and budget constraints. Understanding these differences ensures optimal performance and longevity for your specific application.

Type 200 Nickel vs Type 201 Nickel Infographic

materialdif.com

materialdif.com