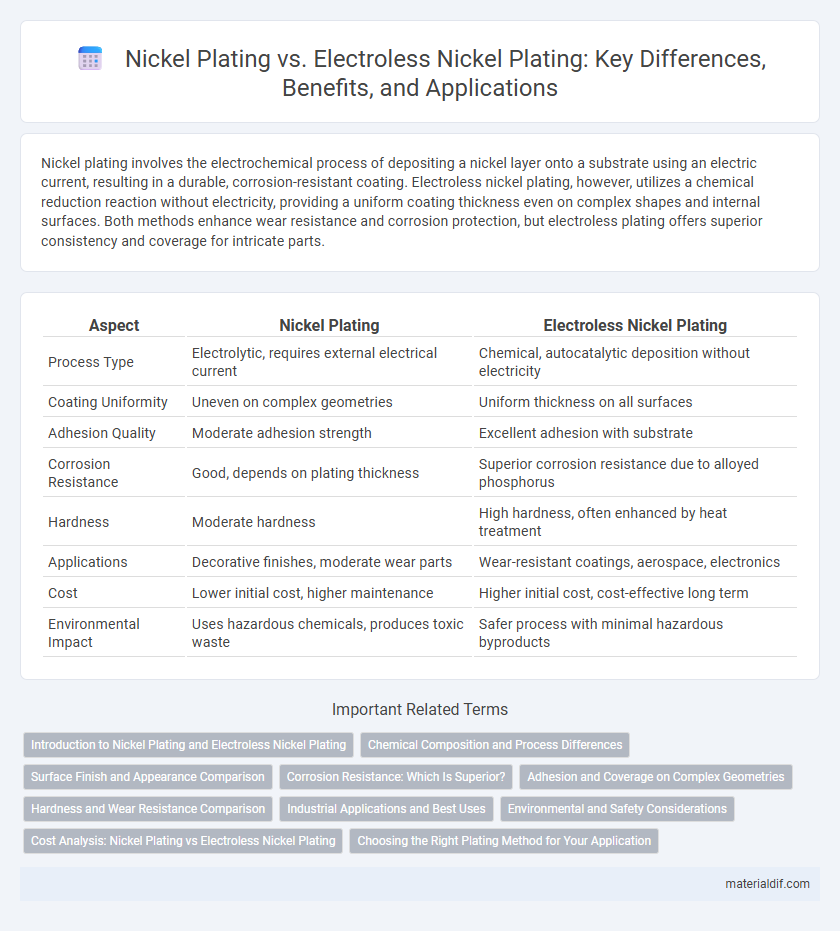

Nickel plating involves the electrochemical process of depositing a nickel layer onto a substrate using an electric current, resulting in a durable, corrosion-resistant coating. Electroless nickel plating, however, utilizes a chemical reduction reaction without electricity, providing a uniform coating thickness even on complex shapes and internal surfaces. Both methods enhance wear resistance and corrosion protection, but electroless plating offers superior consistency and coverage for intricate parts.

Table of Comparison

| Aspect | Nickel Plating | Electroless Nickel Plating |

|---|---|---|

| Process Type | Electrolytic, requires external electrical current | Chemical, autocatalytic deposition without electricity |

| Coating Uniformity | Uneven on complex geometries | Uniform thickness on all surfaces |

| Adhesion Quality | Moderate adhesion strength | Excellent adhesion with substrate |

| Corrosion Resistance | Good, depends on plating thickness | Superior corrosion resistance due to alloyed phosphorus |

| Hardness | Moderate hardness | High hardness, often enhanced by heat treatment |

| Applications | Decorative finishes, moderate wear parts | Wear-resistant coatings, aerospace, electronics |

| Cost | Lower initial cost, higher maintenance | Higher initial cost, cost-effective long term |

| Environmental Impact | Uses hazardous chemicals, produces toxic waste | Safer process with minimal hazardous byproducts |

Introduction to Nickel Plating and Electroless Nickel Plating

Nickel plating involves electrochemical deposition of nickel onto a substrate using an electric current, creating a strong, corrosion-resistant coating that enhances surface hardness and wear resistance. Electroless nickel plating, in contrast, uses a chemical reduction process without electricity, allowing uniform, precise coatings on complex geometries and non-conductive materials. Both methods serve critical roles in industries like aerospace, automotive, and electronics, where durability and corrosion protection are essential.

Chemical Composition and Process Differences

Nickel plating typically uses an electrochemical process where an electric current deposits a layer of nickel from a bath containing nickel salts and additives, resulting in a uniform, electrically conductive coating primarily composed of nickel metal. Electroless nickel plating relies on a chemical reduction reaction using a solution of nickel sulfate, reducing agents like sodium hypophosphite, and stabilizers, producing a nickel-phosphorus alloy layer without the need for electrical current. This chemical composition difference affects the properties and applications, with electroless plating offering superior corrosion resistance and uniform thickness on complex geometries.

Surface Finish and Appearance Comparison

Nickel plating produces a bright, reflective surface with excellent hardness and corrosion resistance, ideal for decorative and functional applications. Electroless nickel plating offers a uniform, matte finish that enhances wear resistance and provides consistent thickness on complex geometries without the need for electrical current. Both methods improve surface durability, but electroless plating delivers superior uniformity and adhesion for industrial components requiring precise coating control.

Corrosion Resistance: Which Is Superior?

Electroless nickel plating offers superior corrosion resistance compared to traditional nickel plating due to its uniform coating, which eliminates weak points and ensures consistent protection even on complex geometries. The chemical deposition process in electroless nickel plating produces a dense, non-porous layer with excellent resistance to oxidation, acids, and alkaline environments. Traditional nickel plating often results in variable thickness and potential gaps, making it less effective in corrosive conditions over time.

Adhesion and Coverage on Complex Geometries

Nickel plating offers strong adhesion due to its electrochemical process, but may struggle with uniform coverage on complex geometries because the electrical current distribution can be uneven. Electroless nickel plating provides consistent thickness and superior coverage on intricate shapes, as its chemical deposition process does not rely on electrical current, leading to excellent adhesion even on recessed or irregular surfaces. This makes electroless nickel plating ideal for components requiring uniform corrosion resistance and wear protection across complex designs.

Hardness and Wear Resistance Comparison

Nickel plating typically uses an electrolytic process that deposits a thin, uniform layer of nickel, providing moderate hardness and wear resistance suitable for decorative and corrosion protection purposes. Electroless nickel plating, however, achieves a chemically deposited coating with higher hardness and superior wear resistance due to its uniform phosphorus or boron content, enhancing surface durability without requiring an external electrical current. The amorphous structure of electroless nickel coatings offers better resistance to abrasion, friction, and corrosion compared to conventional nickel plating.

Industrial Applications and Best Uses

Nickel plating provides a durable, corrosion-resistant coating ideal for automotive parts, aerospace components, and electronics, delivering enhanced wear resistance and electrical conductivity. Electroless nickel plating offers uniform coverage on complex geometries without requiring electrical current, making it suitable for intricate machinery parts, hydraulic components, and printed circuit boards where precision and consistent layer thickness are critical. Both techniques enhance surface hardness and corrosion protection, but electroless nickel plating excels in applications demanding non-conductive substrates and detailed component coverage.

Environmental and Safety Considerations

Nickel plating typically involves hazardous chemicals like cyanide and requires strict ventilation to manage toxic fumes, posing significant environmental and safety risks. Electroless nickel plating eliminates the need for electrical current and toxic cyanide, reducing waste and improving workplace safety by using more environmentally benign chemicals. Both methods require careful waste treatment, but electroless nickel plating generally offers a safer, less environmentally damaging alternative.

Cost Analysis: Nickel Plating vs Electroless Nickel Plating

Nickel plating generally incurs lower upfront costs due to simpler equipment and processes, making it cost-effective for high-volume applications. Electroless nickel plating, while more expensive initially due to chemical and bath maintenance expenses, offers superior uniformity and corrosion resistance that can reduce long-term costs in critical industries. Evaluating total lifecycle expenses, including material durability and maintenance, is essential to determine the most economical choice between nickel plating and electroless nickel plating.

Choosing the Right Plating Method for Your Application

Nickel plating offers a uniform, durable coating ideal for decorative and corrosion-resistant applications, while electroless nickel plating provides a consistent, even layer on complex geometries without the need for an electric current. Selecting the right plating method depends on factors such as substrate material, part complexity, desired thickness, and corrosion resistance requirements. Electroless plating excels in uniformity and hardness, making it preferable for intricate parts, while traditional nickel plating suits applications prioritizing speed and cost-effectiveness.

Nickel Plating vs Electroless Nickel Plating Infographic

materialdif.com

materialdif.com