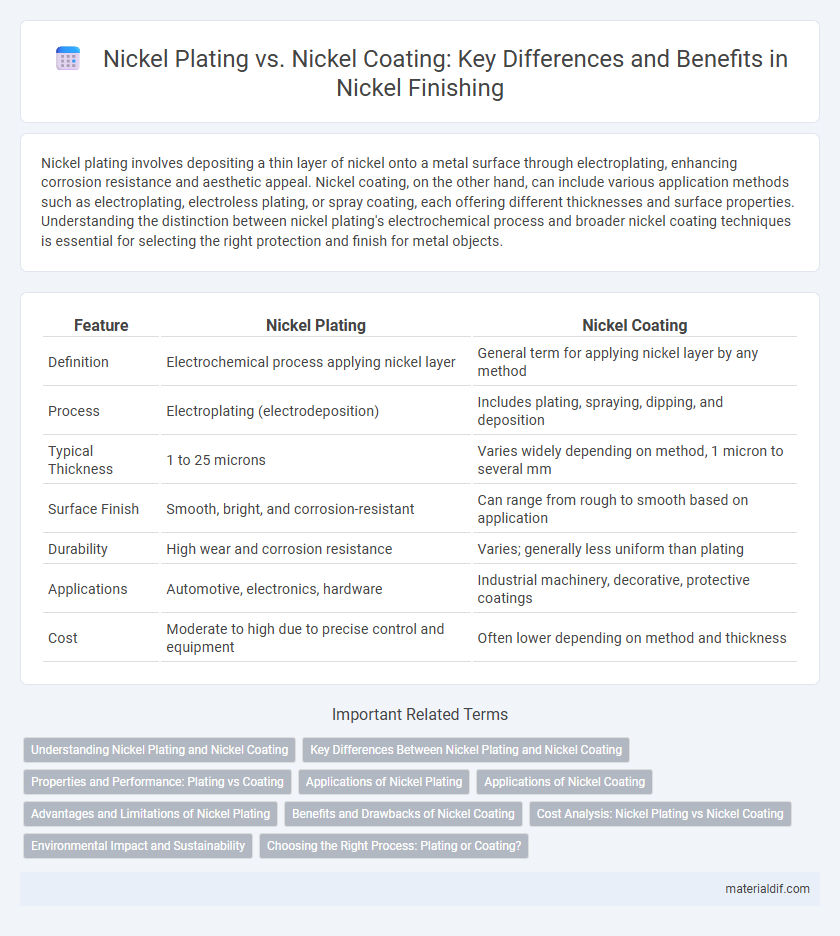

Nickel plating involves depositing a thin layer of nickel onto a metal surface through electroplating, enhancing corrosion resistance and aesthetic appeal. Nickel coating, on the other hand, can include various application methods such as electroplating, electroless plating, or spray coating, each offering different thicknesses and surface properties. Understanding the distinction between nickel plating's electrochemical process and broader nickel coating techniques is essential for selecting the right protection and finish for metal objects.

Table of Comparison

| Feature | Nickel Plating | Nickel Coating |

|---|---|---|

| Definition | Electrochemical process applying nickel layer | General term for applying nickel layer by any method |

| Process | Electroplating (electrodeposition) | Includes plating, spraying, dipping, and deposition |

| Typical Thickness | 1 to 25 microns | Varies widely depending on method, 1 micron to several mm |

| Surface Finish | Smooth, bright, and corrosion-resistant | Can range from rough to smooth based on application |

| Durability | High wear and corrosion resistance | Varies; generally less uniform than plating |

| Applications | Automotive, electronics, hardware | Industrial machinery, decorative, protective coatings |

| Cost | Moderate to high due to precise control and equipment | Often lower depending on method and thickness |

Understanding Nickel Plating and Nickel Coating

Nickel plating involves electrochemical deposition of a thin nickel layer onto a substrate, providing enhanced corrosion resistance and improved surface hardness. Nickel coating may include diverse methods such as electroless plating, thermal spray, or chemical vapor deposition, each offering different thicknesses and properties tailored to specific industrial applications. Understanding the differences in processes and outcomes between nickel plating and nickel coating is crucial for selecting the appropriate technique for corrosion protection, wear resistance, and aesthetic enhancement.

Key Differences Between Nickel Plating and Nickel Coating

Nickel plating involves electrochemically depositing a thin layer of nickel onto a substrate, providing corrosion resistance, enhanced hardness, and improved aesthetic appeal. Nickel coating, often applied through processes like electroless plating or thermal spraying, creates a thicker, more uniform layer that can offer superior wear resistance and uniform coverage on complex geometries. Key differences include the application method, layer thickness, and durability, with nickel plating relying on electricity for deposition and nickel coating encompassing a broader range of techniques that may not require an electrical current.

Properties and Performance: Plating vs Coating

Nickel plating offers a uniform, thin layer that enhances corrosion resistance, wear durability, and electrical conductivity, making it ideal for precision components and electronic parts. Nickel coating, often thicker and applied through thermal or mechanical methods, provides superior protection against abrasion and impact, suitable for heavy-duty industrial applications. The choice between plating and coating depends on specific performance requirements, where plating excels in fine detail and conductivity, while coating maximizes toughness and wear resistance.

Applications of Nickel Plating

Nickel plating offers superior corrosion resistance, wear protection, and enhanced surface hardness, making it ideal for automotive parts, aerospace components, and electronic devices. This electrochemical process creates a uniform, durable layer that improves solderability and aesthetic appeal on metal substrates. Industries rely on nickel plating to extend the lifespan and performance of tools, machinery, and decorative items.

Applications of Nickel Coating

Nickel coating is widely used in industries such as automotive, aerospace, and electronics due to its excellent corrosion resistance, hardness, and wear protection. It enhances surface properties of metals, providing a uniform and durable layer that extends component lifespan in harsh environments. Applications include plating engine parts, electronic connectors, and decorative finishes requiring both functional and aesthetic benefits.

Advantages and Limitations of Nickel Plating

Nickel plating offers superior corrosion resistance, enhanced surface hardness, and improved wear protection, making it ideal for automotive, aerospace, and electronic components. It provides uniform coverage even on complex geometries, ensuring consistent protection, but requires precise control of plating parameters to avoid defects like blistering or peeling. Limitations include environmental concerns due to the use of toxic chemicals and relatively higher production costs compared to other coating methods.

Benefits and Drawbacks of Nickel Coating

Nickel coating provides excellent corrosion resistance and enhances surface hardness, extending the lifespan of metal components in harsh environments. It offers superior wear resistance and an attractive finish but may require more precise application techniques to ensure uniform coverage and avoid defects. The main drawbacks include higher initial costs and potential environmental concerns due to chemical waste generated during the coating process.

Cost Analysis: Nickel Plating vs Nickel Coating

Nickel plating typically involves electrochemical processes that require specialized equipment and skilled labor, resulting in higher initial costs compared to nickel coating techniques such as spray or powder methods. The long-term durability and corrosion resistance of nickel plating often justify its higher expense, especially in industrial applications where component longevity is critical. Nickel coating methods may offer lower upfront costs but generally require more frequent maintenance or reapplication, impacting overall cost efficiency.

Environmental Impact and Sustainability

Nickel plating involves electrochemical deposition creating a thin, uniform layer of nickel, often generating hazardous waste and requiring significant energy consumption. Nickel coating methods such as thermal spraying can minimize waste but might produce powder emissions influencing air quality. Sustainable practices emphasize recycling nickel-containing waste and employing closed-loop systems to reduce environmental impact in both plating and coating processes.

Choosing the Right Process: Plating or Coating?

Nickel plating involves electrochemical deposition of a thin, uniform nickel layer to enhance corrosion resistance and surface hardness, making it ideal for precision tools and automotive parts. Nickel coating, often applied through mechanical means like powder coating or thermal spraying, provides a thicker protective layer suitable for heavy-duty industrial applications where wear resistance is critical. Selecting the right process depends on factors such as desired thickness, surface finish, corrosion protection level, and mechanical stress conditions.

Nickel plating vs Nickel coating Infographic

materialdif.com

materialdif.com