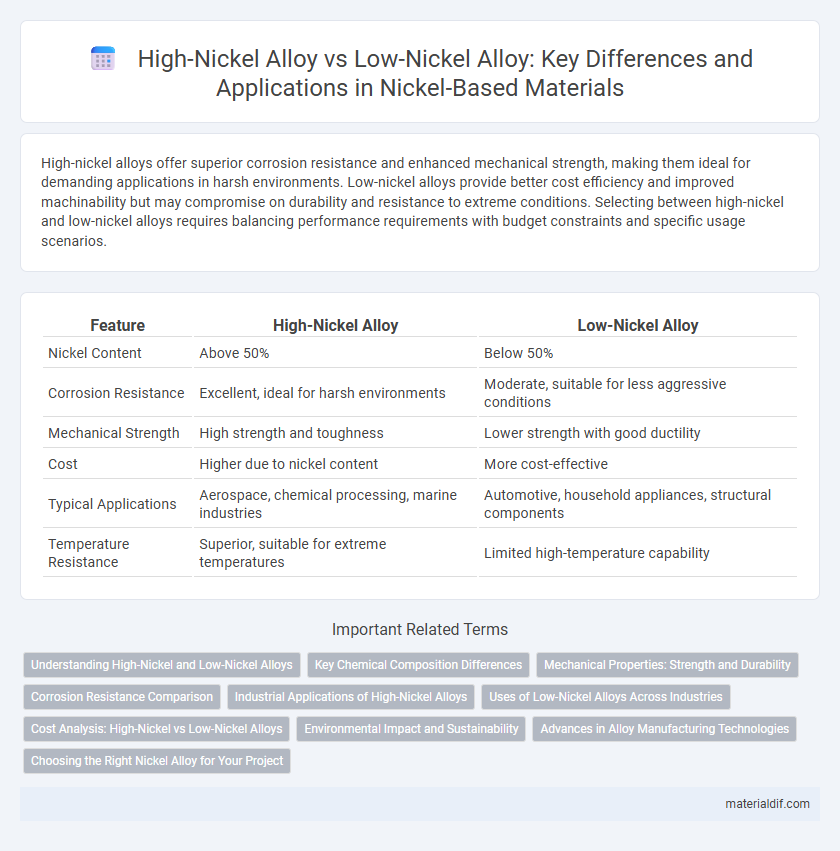

High-nickel alloys offer superior corrosion resistance and enhanced mechanical strength, making them ideal for demanding applications in harsh environments. Low-nickel alloys provide better cost efficiency and improved machinability but may compromise on durability and resistance to extreme conditions. Selecting between high-nickel and low-nickel alloys requires balancing performance requirements with budget constraints and specific usage scenarios.

Table of Comparison

| Feature | High-Nickel Alloy | Low-Nickel Alloy |

|---|---|---|

| Nickel Content | Above 50% | Below 50% |

| Corrosion Resistance | Excellent, ideal for harsh environments | Moderate, suitable for less aggressive conditions |

| Mechanical Strength | High strength and toughness | Lower strength with good ductility |

| Cost | Higher due to nickel content | More cost-effective |

| Typical Applications | Aerospace, chemical processing, marine industries | Automotive, household appliances, structural components |

| Temperature Resistance | Superior, suitable for extreme temperatures | Limited high-temperature capability |

Understanding High-Nickel and Low-Nickel Alloys

High-nickel alloys typically contain more than 30% nickel, enhancing their corrosion resistance, strength, and ability to withstand extreme temperatures, making them ideal for aerospace and chemical processing applications. Low-nickel alloys, with nickel content below 30%, offer better affordability and workability while still providing commendable resistance to oxidation and thermal fatigue. Understanding the distinct physical and chemical properties driven by nickel concentration enables precise alloy selection tailored to specific operational demands.

Key Chemical Composition Differences

High-nickel alloys typically contain nickel content above 50%, often combined with elements like chromium and molybdenum to enhance corrosion resistance and mechanical strength. Low-nickel alloys usually have nickel concentrations below 30%, with higher proportions of iron or other base metals to reduce costs while maintaining basic durability. The distinct nickel percentages significantly influence properties such as oxidation resistance, ductility, and thermal stability, making each alloy suitable for specific industrial applications.

Mechanical Properties: Strength and Durability

High-nickel alloys exhibit superior tensile strength and enhanced corrosion resistance compared to low-nickel alloys, making them ideal for demanding industrial applications. Low-nickel alloys offer moderate strength but excel in toughness and ductility, providing better impact resistance in lower-stress environments. The enhanced durability of high-nickel alloys, attributed to their stable microstructure, ensures prolonged service life under harsh mechanical and thermal conditions.

Corrosion Resistance Comparison

High-nickel alloys exhibit superior corrosion resistance due to their increased nickel content, which enhances passivation and stability in aggressive environments such as acidic and chloride-rich conditions. Low-nickel alloys tend to have lower corrosion resistance and are more susceptible to pitting and stress corrosion cracking, especially in marine and chemical processing applications. The choice between high-nickel and low-nickel alloys depends largely on the exposure severity and required longevity of the material in corrosive atmospheres.

Industrial Applications of High-Nickel Alloys

High-nickel alloys exhibit superior corrosion resistance, high-temperature strength, and excellent mechanical properties, making them crucial in aerospace, chemical processing, and power generation industries. Their ability to withstand extreme environments enables reliable performance in jet engines, gas turbines, and heat exchangers. Industrial applications leverage high-nickel alloys for components exposed to oxidative and corrosive atmospheres, ensuring durability and operational efficiency.

Uses of Low-Nickel Alloys Across Industries

Low-nickel alloys are widely utilized in chemical processing equipment due to their excellent corrosion resistance in acidic environments. These alloys are essential in manufacturing household appliances and food processing machinery, where low nickel content reduces cost while maintaining durability. The medical industry also favors low-nickel alloys for surgical instruments and implants to minimize allergic reactions among patients.

Cost Analysis: High-Nickel vs Low-Nickel Alloys

High-nickel alloys typically demand higher material costs due to the increased percentage of nickel, which is a premium metal with price volatility influenced by global supply constraints and industrial demand. Low-nickel alloys offer a cost-effective alternative by reducing the nickel content while maintaining essential mechanical properties, leading to significant savings in large-scale manufacturing. When comparing total lifecycle costs, high-nickel alloys may yield better corrosion resistance and durability, potentially offsetting initial expenses through extended service life and reduced maintenance.

Environmental Impact and Sustainability

High-nickel alloys offer superior corrosion resistance and longer lifespan, reducing the frequency of replacements and minimizing waste generation. Low-nickel alloys typically require more frequent maintenance and have a shorter lifecycle, which can increase resource consumption and environmental footprint. Sustainable alloy selection balances nickel content with lifecycle impact, emphasizing recycling potential and energy-efficient production methods to lower overall carbon emissions.

Advances in Alloy Manufacturing Technologies

High-nickel alloys exhibit superior corrosion resistance and mechanical strength due to advanced manufacturing technologies such as powder metallurgy and additive manufacturing, which enable precise control over microstructure and composition. Low-nickel alloys benefit from recent developments in thermomechanical processing and alloying element optimization, enhancing their ductility and cost-effectiveness while maintaining adequate performance in less demanding environments. Innovations in rapid solidification and nano-scale alloying have improved the performance and reliability of both high- and low-nickel alloys across aerospace, chemical processing, and energy industries.

Choosing the Right Nickel Alloy for Your Project

High-nickel alloys offer superior corrosion resistance, high strength, and excellent performance in extreme temperatures, making them ideal for aerospace and chemical processing industries. Low-nickel alloys provide better cost efficiency and are sufficient for applications with moderate environmental stress, such as plumbing and structural components. Choosing the right nickel alloy depends on balancing factors like mechanical properties, environmental conditions, and budget constraints to ensure optimal project outcomes.

High-Nickel Alloy vs Low-Nickel Alloy Infographic

materialdif.com

materialdif.com