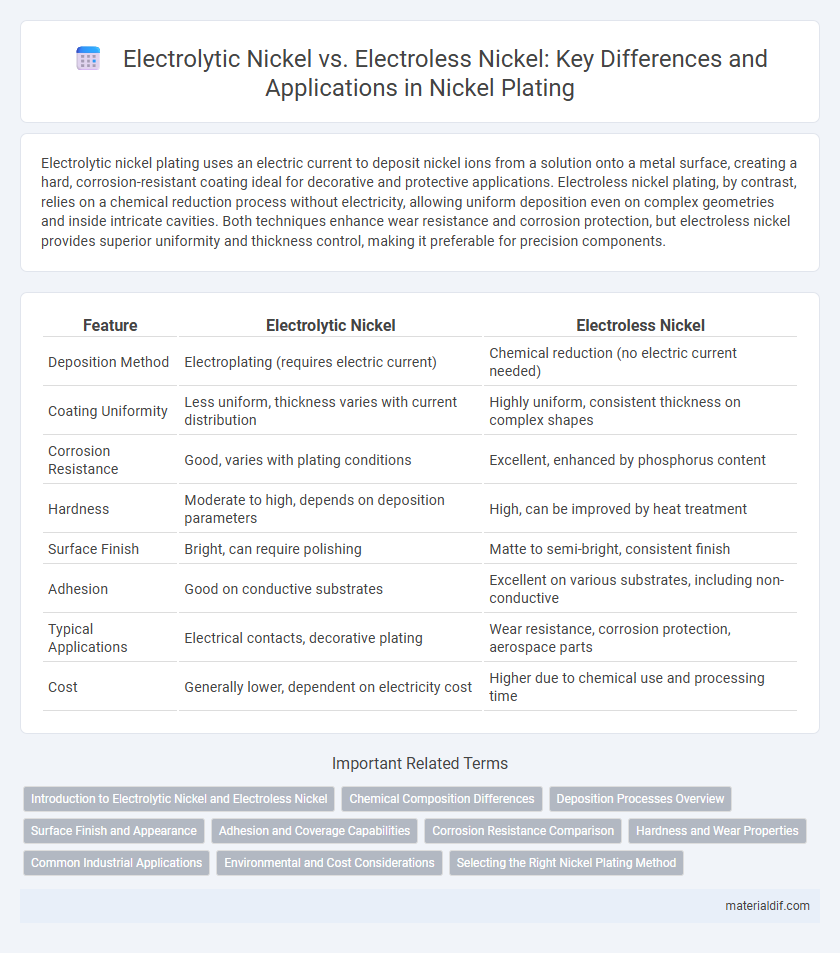

Electrolytic nickel plating uses an electric current to deposit nickel ions from a solution onto a metal surface, creating a hard, corrosion-resistant coating ideal for decorative and protective applications. Electroless nickel plating, by contrast, relies on a chemical reduction process without electricity, allowing uniform deposition even on complex geometries and inside intricate cavities. Both techniques enhance wear resistance and corrosion protection, but electroless nickel provides superior uniformity and thickness control, making it preferable for precision components.

Table of Comparison

| Feature | Electrolytic Nickel | Electroless Nickel |

|---|---|---|

| Deposition Method | Electroplating (requires electric current) | Chemical reduction (no electric current needed) |

| Coating Uniformity | Less uniform, thickness varies with current distribution | Highly uniform, consistent thickness on complex shapes |

| Corrosion Resistance | Good, varies with plating conditions | Excellent, enhanced by phosphorus content |

| Hardness | Moderate to high, depends on deposition parameters | High, can be improved by heat treatment |

| Surface Finish | Bright, can require polishing | Matte to semi-bright, consistent finish |

| Adhesion | Good on conductive substrates | Excellent on various substrates, including non-conductive |

| Typical Applications | Electrical contacts, decorative plating | Wear resistance, corrosion protection, aerospace parts |

| Cost | Generally lower, dependent on electricity cost | Higher due to chemical use and processing time |

Introduction to Electrolytic Nickel and Electroless Nickel

Electrolytic nickel is produced through an electroplating process, where nickel ions are deposited onto a substrate using an electric current, resulting in a uniform, corrosion-resistant coating often used in automotive and electronics industries. Electroless nickel, or chemical nickel plating, involves an autocatalytic reaction that deposits nickel-phosphorus or nickel-boron alloys without electricity, providing superior wear resistance and uniform coverage on complex geometries. Both methods enhance surface durability and corrosion protection but differ in application techniques, coating properties, and cost efficiency.

Chemical Composition Differences

Electrolytic nickel primarily consists of pure nickel deposited through an electric current, typically containing over 99% nickel with minimal impurities. Electroless nickel, by contrast, is an autocatalytic chemical plating process that deposits a nickel-phosphorus or nickel-boron alloy, with phosphorus content ranging from 2% to 14%, significantly altering its chemical composition and properties. The presence of phosphorus or boron in electroless nickel enhances corrosion resistance and hardness compared to the nearly pure nickel layer formed by electrolytic deposition.

Deposition Processes Overview

Electrolytic nickel deposition involves an electroplating process where nickel ions are reduced onto a conductive substrate through the application of an electric current, resulting in a uniform metallic coating. Electroless nickel deposition relies on a chemical reduction reaction without external electrical input, enabling uniform coverage on complex shapes and non-conductive surfaces. Both processes use nickel sulfate or nickel hypophosphite baths, but electroless plating offers advantages in corrosion resistance and wear properties due to phosphorus incorporation.

Surface Finish and Appearance

Electrolytic nickel coatings typically exhibit a brighter and smoother surface finish due to the controlled deposition process using an external current, resulting in a more uniform and lustrous appearance. Electroless nickel plating offers a more consistent thickness and excellent corrosion resistance with a matte to satin finish, making it ideal for applications requiring uniform coverage on complex geometries. Both techniques enhance surface hardness and wear resistance, but electrolytic nickel is preferred for decorative applications where a shiny, polished look is essential.

Adhesion and Coverage Capabilities

Electrolytic nickel plating offers excellent adhesion due to its ionic bonding process, resulting in a uniform and durable coating ideal for applications requiring strong mechanical bonding. Electroless nickel plating provides superior coverage, including complex and recessed areas, thanks to its autocatalytic chemical deposition that ensures consistent thickness without electrical current. While electrolytic nickel is favored for thicker, more wear-resistant layers, electroless nickel excels in achieving flawless, even coatings on intricate geometries with enhanced corrosion resistance.

Corrosion Resistance Comparison

Electrolytic nickel plating provides a uniform and dense coating that offers excellent corrosion resistance, particularly against acidic environments and salt spray conditions. Electroless nickel, with its autocatalytic deposition process, delivers superior corrosion protection due to its phosphorus content, which enhances resistance to oxidation and wear in harsh environments. Comparatively, electroless nickel generally outperforms electrolytic nickel in corrosion resistance, especially on complex geometries and non-conductive surfaces.

Hardness and Wear Properties

Electrolytic nickel typically exhibits higher hardness levels, often reaching up to 700 HV, making it suitable for applications requiring superior wear resistance. Electroless nickel, with hardness values around 500-600 HV after heat treatment, offers uniform coating thickness and excellent corrosion resistance along with good wear properties. The choice between electrolytic and electroless nickel depends on the balance needed between hardness, wear durability, and coating uniformity for specific industrial uses.

Common Industrial Applications

Electrolytic nickel is widely used in battery manufacturing, aerospace components, and electrical contacts due to its high purity and excellent conductivity. Electroless nickel coating is commonly applied in automotive parts, electronics, and oilfield equipment, offering uniform corrosion resistance and enhanced wear properties. Both processes serve critical roles in industrial sectors requiring precise surface characteristics and durability.

Environmental and Cost Considerations

Electrolytic nickel plating consumes more energy due to its reliance on electrical current, leading to higher operational costs and a larger environmental footprint compared to electroless nickel, which uses chemical reduction and operates at lower temperatures. Electroless nickel provides uniform coating without requiring electrical power, reducing energy consumption and offering better corrosion resistance, lowering maintenance expenses over time. Waste disposal from electrolytic plating often contains heavy metals and acids, increasing environmental hazards and treatment costs, whereas electroless nickel baths generate fewer toxic byproducts, making it a more eco-friendly option.

Selecting the Right Nickel Plating Method

Selecting the right nickel plating method depends on the application requirements, with electrolytic nickel providing superior thickness control and enhanced adhesion for heavy-duty corrosion resistance, while electroless nickel offers uniform coating on complex geometries without the need for electrical current. Electrolytic nickel plating excels in industries like automotive and aerospace where precise electrochemical deposition is crucial, whereas electroless nickel is preferred for electronics and intricate parts due to its consistent nickel-phosphorus alloy layer. Understanding the operational environment and desired properties such as hardness, wear resistance, and uniformity ensures optimal performance and longevity in nickel-plated components.

Electrolytic Nickel vs Electroless Nickel Infographic

materialdif.com

materialdif.com