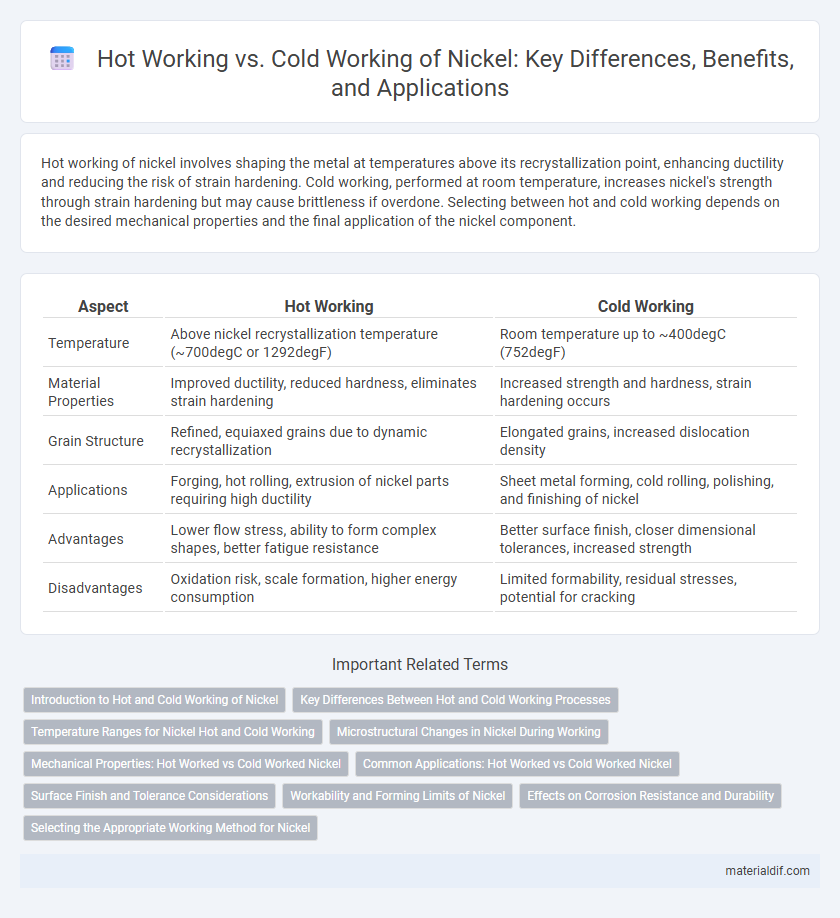

Hot working of nickel involves shaping the metal at temperatures above its recrystallization point, enhancing ductility and reducing the risk of strain hardening. Cold working, performed at room temperature, increases nickel's strength through strain hardening but may cause brittleness if overdone. Selecting between hot and cold working depends on the desired mechanical properties and the final application of the nickel component.

Table of Comparison

| Aspect | Hot Working | Cold Working |

|---|---|---|

| Temperature | Above nickel recrystallization temperature (~700degC or 1292degF) | Room temperature up to ~400degC (752degF) |

| Material Properties | Improved ductility, reduced hardness, eliminates strain hardening | Increased strength and hardness, strain hardening occurs |

| Grain Structure | Refined, equiaxed grains due to dynamic recrystallization | Elongated grains, increased dislocation density |

| Applications | Forging, hot rolling, extrusion of nickel parts requiring high ductility | Sheet metal forming, cold rolling, polishing, and finishing of nickel |

| Advantages | Lower flow stress, ability to form complex shapes, better fatigue resistance | Better surface finish, closer dimensional tolerances, increased strength |

| Disadvantages | Oxidation risk, scale formation, higher energy consumption | Limited formability, residual stresses, potential for cracking |

Introduction to Hot and Cold Working of Nickel

Hot working of nickel involves deforming the metal at temperatures above its recrystallization point, enhancing its ductility and allowing significant shape changes without cracking. Cold working occurs below this temperature, increasing the strength and hardness of nickel through strain hardening while reducing ductility. Both processes influence the microstructure and mechanical properties of nickel, making them crucial for tailoring material performance in industrial applications.

Key Differences Between Hot and Cold Working Processes

Hot working of nickel involves deforming the metal above its recrystallization temperature, enhancing ductility and reducing the risk of strain hardening, whereas cold working occurs below this temperature, increasing strength through strain hardening but reducing ductility. Hot working processes, such as hot rolling and forging, enable significant shape changes and improved grain structure, while cold working processes, including cold rolling and drawing, produce higher surface finish quality and dimensional accuracy. Temperature control in hot working prevents crack formation in nickel, whereas cold working requires subsequent annealing to relieve internal stresses and restore ductility.

Temperature Ranges for Nickel Hot and Cold Working

Nickel typically undergoes hot working at temperatures ranging from 900degC to 1200degC, which enhances its ductility and reduces strain hardening, allowing for significant deformation without cracking. Cold working is performed below 300degC, where the metal exhibits increased strength and hardness due to strain hardening, but reduced ductility limits deformation. Maintaining precise temperature control during hot and cold working is crucial to optimize nickel's mechanical properties and avoid defects.

Microstructural Changes in Nickel During Working

Hot working of nickel causes significant microstructural changes, including dynamic recrystallization and grain refinement, which enhance ductility and reduce residual stresses. Cold working results in strain hardening, increased dislocation density, and elongated grain structures that improve strength but decrease ductility. Temperature plays a critical role in controlling phase stability and mechanical properties during these deformation processes.

Mechanical Properties: Hot Worked vs Cold Worked Nickel

Hot worked nickel exhibits improved ductility and reduced residual stresses due to recrystallization at elevated temperatures, resulting in enhanced toughness and resistance to crack propagation. Cold worked nickel demonstrates increased strength and hardness through strain hardening, but this comes at the expense of decreased ductility and higher susceptibility to stress corrosion cracking. Mechanical properties of nickel are thus significantly influenced by the thermal and mechanical history, with hot working favored for applications requiring flexibility and cold working preferred when strength and hardness are critical.

Common Applications: Hot Worked vs Cold Worked Nickel

Hot worked nickel is commonly used in applications requiring enhanced ductility and complex shapes, such as turbine blades and aerospace components, where elevated temperatures improve formability and reduce residual stresses. Cold worked nickel is favored for applications demanding high strength and improved surface finish, like electrical connectors and precision springs, as the process increases hardness and dimensional accuracy. Selecting hot or cold working depends on the specific mechanical properties and dimensional tolerances needed for nickel in industrial uses.

Surface Finish and Tolerance Considerations

Hot working of nickel results in a rougher surface finish due to oxidation and scale formation at elevated temperatures, whereas cold working produces a smoother surface with tighter dimensional tolerances. Cold working enhances nickel's surface finish quality by minimizing surface defects and allows for precise control over final dimensions, ideal for applications requiring high accuracy. Surface finish and tolerance considerations favor cold working when aesthetic appearance and exact measurements are critical, while hot working is suitable for bulk shaping where surface imperfections are less impactful.

Workability and Forming Limits of Nickel

Nickel exhibits superior workability during hot working processes due to enhanced atomic mobility and reduced yield strength at elevated temperatures, enabling extensive plastic deformation without fracture. Cold working of nickel improves strength and hardness through strain hardening but significantly reduces ductility and forming limits, increasing the risk of cracking under high strain. Optimal forming of nickel balances temperature, strain rate, and deformation extent to maximize formability while minimizing defects.

Effects on Corrosion Resistance and Durability

Hot working of nickel enhances its corrosion resistance by promoting a more homogeneous microstructure and reducing internal stresses, which minimizes susceptibility to stress-corrosion cracking. Cold working increases dislocation density and strain hardening, potentially lowering corrosion resistance due to heightened residual stresses and surface defects. Hot worked nickel typically exhibits superior durability in corrosive environments compared to cold worked counterparts, making it preferable for applications requiring long-term corrosion resistance.

Selecting the Appropriate Working Method for Nickel

Hot working of nickel involves deforming the metal above its recrystallization temperature, enhancing ductility and reducing the risk of cracking, which is essential for shaping complex components. Cold working occurs below the recrystallization temperature, increasing strength and hardness through strain hardening, but may require subsequent annealing to restore ductility. Selecting the appropriate working method for nickel depends on the desired mechanical properties, component complexity, and production efficiency.

Hot Working vs Cold Working (Nickel) Infographic

materialdif.com

materialdif.com