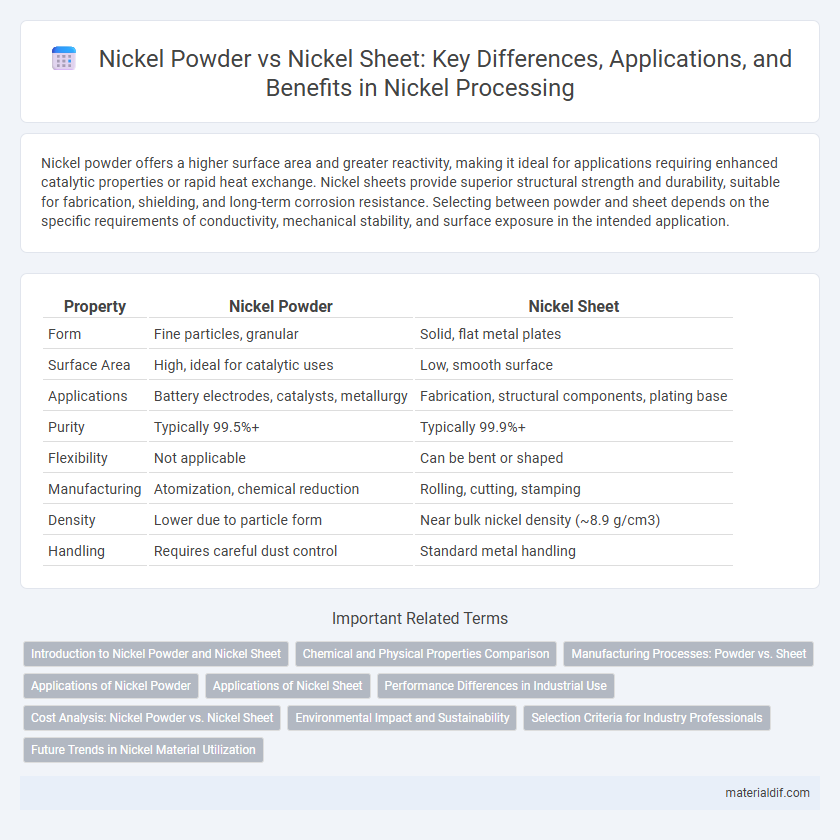

Nickel powder offers a higher surface area and greater reactivity, making it ideal for applications requiring enhanced catalytic properties or rapid heat exchange. Nickel sheets provide superior structural strength and durability, suitable for fabrication, shielding, and long-term corrosion resistance. Selecting between powder and sheet depends on the specific requirements of conductivity, mechanical stability, and surface exposure in the intended application.

Table of Comparison

| Property | Nickel Powder | Nickel Sheet |

|---|---|---|

| Form | Fine particles, granular | Solid, flat metal plates |

| Surface Area | High, ideal for catalytic uses | Low, smooth surface |

| Applications | Battery electrodes, catalysts, metallurgy | Fabrication, structural components, plating base |

| Purity | Typically 99.5%+ | Typically 99.9%+ |

| Flexibility | Not applicable | Can be bent or shaped |

| Manufacturing | Atomization, chemical reduction | Rolling, cutting, stamping |

| Density | Lower due to particle form | Near bulk nickel density (~8.9 g/cm3) |

| Handling | Requires careful dust control | Standard metal handling |

Introduction to Nickel Powder and Nickel Sheet

Nickel powder consists of fine, granular particles used extensively in battery electrodes, catalysts, and additive manufacturing due to its high surface area and reactivity. Nickel sheet is a solid, flat form ideal for corrosion-resistant applications, electrical components, and structural materials requiring durability and uniform thickness. Both forms capitalize on nickel's excellent corrosion resistance, magnetic properties, and conductivity but serve distinct industrial roles based on their physical characteristics.

Chemical and Physical Properties Comparison

Nickel powder exhibits a high surface area and enhanced reactivity due to its fine particulate form, making it ideal for catalytic applications and electrode manufacturing. In contrast, nickel sheets possess superior mechanical strength, corrosion resistance, and thermal conductivity, suitable for structural components and protective coatings. Chemically, both forms maintain excellent resistance to oxidation and corrosion, but the powder's increased surface area can accelerate oxidation compared to the dense, compact structure of nickel sheets.

Manufacturing Processes: Powder vs. Sheet

Nickel powder is manufactured through atomization, chemical reduction, or electrolysis, producing fine particles that enable precise control over grain size and surface area for specialized applications. Nickel sheets are produced via hot rolling and cold rolling processes, followed by annealing to enhance mechanical properties and surface finish. The powder process allows for versatility in molding and sintering, while sheet production is optimized for uniform thickness and structural integrity in industrial uses.

Applications of Nickel Powder

Nickel powder is widely used in applications such as battery electrodes, catalyst production, and additive manufacturing due to its high surface area and excellent conductivity. Its fine particulate form enhances chemical reactivity and allows precise control in processes like electroplating, rechargeable batteries, and hydrogen storage. Unlike nickel sheets, which are primarily utilized for structural components and corrosion-resistant coatings, nickel powder excels in chemical processing and energy storage industries.

Applications of Nickel Sheet

Nickel sheet is extensively used in aerospace, automotive, and chemical processing industries due to its excellent corrosion resistance and high-temperature strength. It is ideal for manufacturing heat exchangers, turbine blades, and electroplating anodes where durability and conductivity are critical. The flat, uniform surface of nickel sheets enables easy fabrication into precise components compared to the granular form of nickel powder.

Performance Differences in Industrial Use

Nickel powder offers enhanced surface area and faster reaction rates, making it ideal for catalytic applications and battery electrodes in industrial settings. Nickel sheets provide superior structural integrity and corrosion resistance, preferred in manufacturing durable components and heat exchangers. Performance differences hinge on the specific industrial use, where powder excels in chemical reactivity and sheets are favored for mechanical strength and longevity.

Cost Analysis: Nickel Powder vs. Nickel Sheet

Nickel powder typically offers a lower upfront cost compared to nickel sheet due to its manufacturing process and bulk production methods, making it cost-effective for applications requiring large surface areas or intricate shapes. Nickel sheets, however, incur higher material and fabrication costs but provide superior mechanical strength and uniformity, justifying the premium in structural or high-stress applications. Evaluating the total cost of ownership involves balancing the cheaper initial investment of nickel powder against the durability and performance benefits of nickel sheets, depending on specific application requirements.

Environmental Impact and Sustainability

Nickel powder production generates more particulate emissions and energy consumption compared to nickel sheets, impacting air quality and resource use. Nickel sheets offer longer durability and recyclability, reducing raw material demands and waste in industrial applications. Choosing nickel sheets over powder can significantly lower environmental footprints and enhance sustainability in metal manufacturing processes.

Selection Criteria for Industry Professionals

Industry professionals select nickel powder for applications requiring high surface area and improved reactivity, such as catalysts and battery electrodes. Nickel sheets are preferred for structural uses demanding mechanical strength, corrosion resistance, and ease of fabrication in aerospace, automotive, and electronics industries. Key selection criteria include surface morphology, purity levels, mechanical properties, and the specific requirements of conductivity and thermal stability.

Future Trends in Nickel Material Utilization

Emerging advancements in battery technology and additive manufacturing drive increased demand for nickel powder due to its enhanced surface area and reactivity compared to traditional nickel sheets. The shift towards electric vehicles and renewable energy storage solutions is accelerating the adoption of nickel powder in high-capacity lithium-ion batteries, promoting superior energy density and faster charge cycles. Innovations in powder metallurgy also enable precise alloy formulations, positioning nickel powder as a critical material in future industrial and energy applications over conventional nickel sheets.

Nickel Powder vs Nickel Sheet Infographic

materialdif.com

materialdif.com