Nickel-copper alloy offers exceptional corrosion resistance and excellent thermal conductivity, making it ideal for marine and electronic applications. Nickel-chromium alloy provides superior oxidation resistance and high-temperature strength, commonly used in heating elements and aerospace components. Choosing between these alloys depends on the balance of environmental durability and mechanical performance required by the specific application.

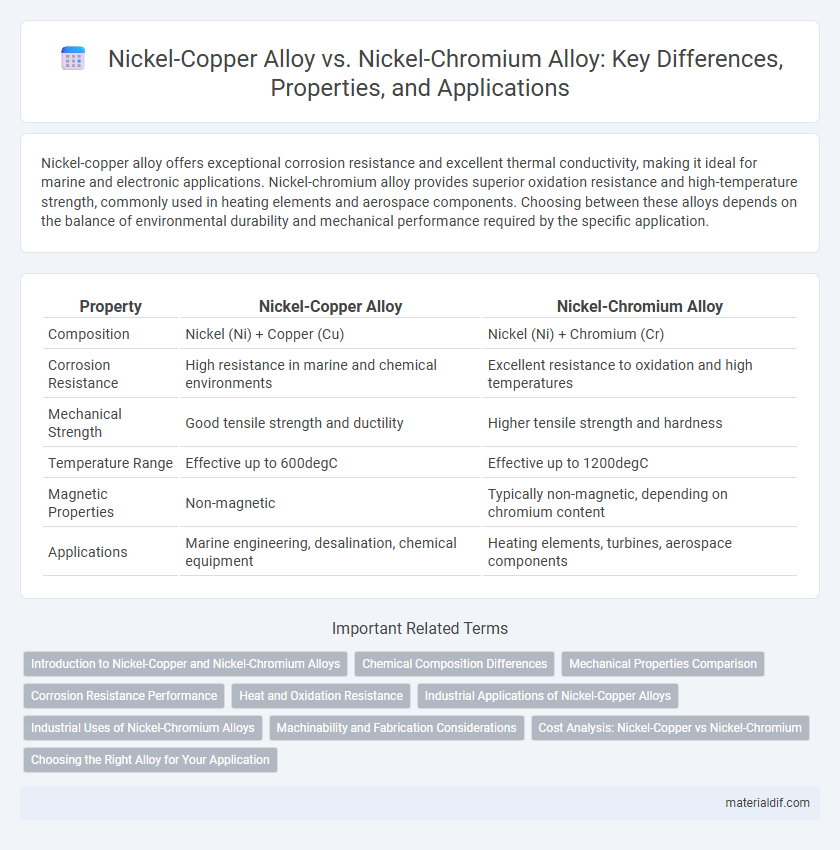

Table of Comparison

| Property | Nickel-Copper Alloy | Nickel-Chromium Alloy |

|---|---|---|

| Composition | Nickel (Ni) + Copper (Cu) | Nickel (Ni) + Chromium (Cr) |

| Corrosion Resistance | High resistance in marine and chemical environments | Excellent resistance to oxidation and high temperatures |

| Mechanical Strength | Good tensile strength and ductility | Higher tensile strength and hardness |

| Temperature Range | Effective up to 600degC | Effective up to 1200degC |

| Magnetic Properties | Non-magnetic | Typically non-magnetic, depending on chromium content |

| Applications | Marine engineering, desalination, chemical equipment | Heating elements, turbines, aerospace components |

Introduction to Nickel-Copper and Nickel-Chromium Alloys

Nickel-copper alloys, commonly known as cupronickel, consist primarily of nickel and copper, offering excellent corrosion resistance and thermal conductivity that make them ideal for marine and coinage applications. Nickel-chromium alloys contain significant amounts of chromium, enhancing their oxidation resistance and strength at high temperatures, which is essential for aerospace and heating elements. Both alloy types leverage nickel's intrinsic durability but differ in their chemical makeup and performance characteristics tailored to specific industrial needs.

Chemical Composition Differences

Nickel-copper alloys primarily consist of nickel (60-90%) and copper (10-40%), offering excellent corrosion resistance and electrical conductivity due to the copper content. In contrast, nickel-chromium alloys contain significant amounts of chromium (10-30%) alongside nickel (50-80%), providing superior oxidation resistance and high-temperature strength. The chemical composition differences influence their applications: nickel-copper alloys excel in marine environments, while nickel-chromium alloys are preferred for heating elements and turbine components.

Mechanical Properties Comparison

Nickel-copper alloys typically exhibit superior corrosion resistance and enhanced ductility, making them ideal for marine and chemical environments, whereas nickel-chromium alloys provide higher tensile strength and improved oxidation resistance, suitable for high-temperature applications. The mechanical properties of nickel-chromium alloys include greater hardness and creep resistance compared to the more flexible and fatigue-resistant behavior of nickel-copper alloys. These distinctions make nickel-copper alloys preferable for applications requiring toughness and corrosion endurance, while nickel-chromium alloys excel in mechanical stability under thermal stress and wear.

Corrosion Resistance Performance

Nickel-Copper alloys exhibit superior corrosion resistance in marine and acidic environments due to their enhanced resistance to pitting and crevice corrosion. Nickel-Chromium alloys offer excellent high-temperature oxidation resistance and are more effective in resisting oxidizing environments and thermal degradation. Both alloys provide strong corrosion resistance, but Nickel-Copper alloys are generally preferred for aqueous and chloride-rich conditions, while Nickel-Chromium alloys excel in high-temperature and oxidative settings.

Heat and Oxidation Resistance

Nickel-copper alloys exhibit excellent corrosion resistance but moderate heat and oxidation resistance, making them suitable for marine and chemical environments. Nickel-chromium alloys provide superior heat resistance up to 1100degC and form a stable oxide layer, enhancing oxidation resistance for high-temperature applications like turbine engines and heat exchangers. The chromium content in nickel-chromium alloys significantly boosts oxidation resistance compared to nickel-copper alloys.

Industrial Applications of Nickel-Copper Alloys

Nickel-copper alloys exhibit exceptional corrosion resistance and electrical conductivity, making them ideal for marine engineering, chemical processing, and electrical components. These alloys thrive in harsh environments where resistance to chloride stress corrosion cracking is critical, outperforming many nickel-chromium alloys under such conditions. Industrial applications leverage nickel-copper's robustness in heat exchangers, desalination plants, and condenser tubes, benefiting from its superior thermal stability and antifouling properties.

Industrial Uses of Nickel-Chromium Alloys

Nickel-chromium alloys are extensively used in industrial applications requiring high resistance to oxidation and corrosion at elevated temperatures, such as heating elements in furnaces, gas turbines, and aerospace components. Unlike nickel-copper alloys, which excel in electrical conductivity and marine resistance, nickel-chromium alloys provide superior mechanical strength and stability under thermal stress. Their ability to form protective oxide layers makes them ideal for use in chemical processing equipment and heat exchangers.

Machinability and Fabrication Considerations

Nickel-Copper alloys exhibit superior machinability compared to Nickel-Chromium alloys due to their lower hardness and higher ductility, enabling easier cutting and shaping processes. Fabrication of Nickel-Copper alloys requires less tool wear and offers better weldability, making them ideal for complex geometries and applications involving corrosion resistance in marine environments. In contrast, Nickel-Chromium alloys possess enhanced strength and oxidation resistance but demand specialized machining techniques and higher precision due to their increased hardness and work-hardening characteristics.

Cost Analysis: Nickel-Copper vs Nickel-Chromium

Nickel-copper alloys generally offer a lower material cost compared to nickel-chromium alloys due to the relative abundance and cheaper price of copper versus chromium. The manufacturing process expenses also tend to be reduced with nickel-copper alloys, as they require less energy-intensive treatments and lower equipment maintenance. Economic evaluation shows nickel-copper alloys are more cost-effective for applications needing good corrosion resistance without the higher thermal stability and hardness provided by nickel-chromium alloys.

Choosing the Right Alloy for Your Application

Nickel-copper alloys offer excellent corrosion resistance and superior electrical conductivity, making them ideal for marine and electrical components. Nickel-chromium alloys excel in high-temperature stability and oxidation resistance, suitable for heating elements and aerospace applications. Selecting the right alloy depends on factors like environmental exposure, thermal requirements, and mechanical strength needed for your specific application.

Nickel-Copper Alloy vs Nickel-Chromium Alloy Infographic

materialdif.com

materialdif.com