Refined nickel offers higher purity levels that enhance its corrosion resistance and conductivity, making it ideal for advanced industrial applications. Unrefined nickel contains impurities that can affect mechanical properties and limit its use in precision manufacturing. Choosing between refined and unrefined nickel depends on specific requirements for quality, performance, and cost efficiency in the intended application.

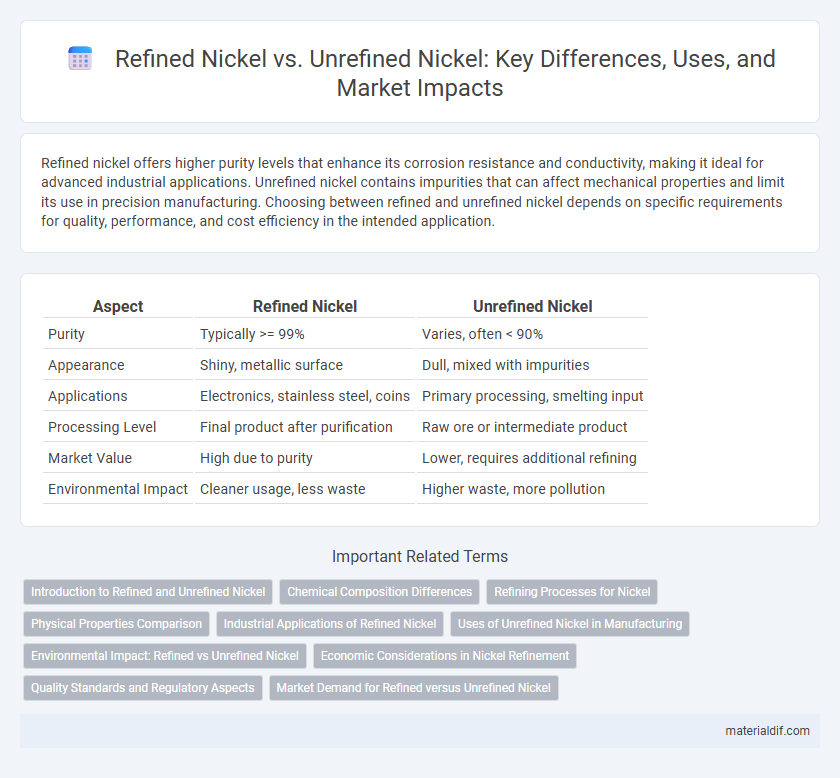

Table of Comparison

| Aspect | Refined Nickel | Unrefined Nickel |

|---|---|---|

| Purity | Typically >= 99% | Varies, often < 90% |

| Appearance | Shiny, metallic surface | Dull, mixed with impurities |

| Applications | Electronics, stainless steel, coins | Primary processing, smelting input |

| Processing Level | Final product after purification | Raw ore or intermediate product |

| Market Value | High due to purity | Lower, requires additional refining |

| Environmental Impact | Cleaner usage, less waste | Higher waste, more pollution |

Introduction to Refined and Unrefined Nickel

Refined nickel is purer, typically containing over 99% nickel content, achieved through processes like electrolytic refining or carbonyl refining, making it suitable for high-performance applications such as stainless steel production and battery manufacturing. Unrefined nickel, often found as ore or matte, contains various impurities including iron, sulfur, and other metals, requiring further processing before industrial use. Understanding the distinction between refined and unrefined nickel is crucial for industries that demand specific purity levels and material properties.

Chemical Composition Differences

Refined nickel typically contains a purity level of over 99%, with minimal impurities such as sulfur, iron, and copper, ensuring consistent chemical composition for industrial applications. Unrefined nickel, often in the form of nickel matte or ore concentrate, contains variable amounts of sulfides, iron, and other metals, resulting in a heterogeneous chemical profile. These compositional differences directly impact the metal's suitability for processes like electroplating, alloy production, and battery manufacturing.

Refining Processes for Nickel

Refined nickel undergoes a series of complex refining processes such as the Mond process, electrolytic refining, and hydrometallurgical methods to achieve high purity levels exceeding 99.8%, essential for stainless steel manufacturing and battery applications. Unrefined nickel, commonly found as nickel matte or sulfide concentrates, contains impurities like sulfur, iron, and copper, requiring sequential treatment steps including roasting, smelting, and leaching to isolate pure nickel. Advanced refining technologies enhance nickel recovery efficiency and reduce environmental impact, supporting the production of high-quality nickel for industrial and technological uses.

Physical Properties Comparison

Refined nickel exhibits a higher purity level, typically above 99.8%, resulting in enhanced physical properties such as increased ductility, malleability, and corrosion resistance compared to unrefined nickel, which contains impurities that can weaken its structural integrity. Unrefined nickel often has a lower melting point due to contaminants and demonstrates more variability in tensile strength and hardness. The controlled microstructure of refined nickel ensures consistent physical behavior critical for industrial applications like stainless steel production and aerospace components.

Industrial Applications of Refined Nickel

Refined nickel offers superior purity and enhanced corrosion resistance, making it essential for stainless steel production, aerospace components, and electroplating industries. Its high-quality properties enable efficient performance in battery manufacturing, particularly for electric vehicles and renewable energy storage systems. Industrial applications rely on refined nickel for durability and conductivity, distinguishing it significantly from unrefined nickel products.

Uses of Unrefined Nickel in Manufacturing

Unrefined nickel, containing impurities such as sulfur and iron, is primarily used in manufacturing processes where purity is less critical but durability is essential, such as in alloy production for stainless steel and battery components. Its cost-effectiveness and natural properties make it suitable for creating corrosion-resistant parts in the automotive, aerospace, and construction industries. Industrial applications also include plating and coatings to enhance surface hardness and chemical resistance in machinery and tools.

Environmental Impact: Refined vs Unrefined Nickel

Refined nickel undergoes processes that reduce harmful impurities, resulting in lower emissions and waste compared to unrefined nickel, which often contains toxic elements that can leach into soil and water. The energy-intensive nature of refining contributes to carbon emissions, but advanced technologies and recycling initiatives help mitigate environmental damage. Unrefined nickel's extraction and handling pose higher ecological risks due to habitat disruption and contamination from untreated ores.

Economic Considerations in Nickel Refinement

Refined nickel commands higher market prices due to its improved purity, making it essential for high-value industries such as stainless steel manufacturing and battery production. The cost-intensive refining processes require significant capital investment but yield nickel with superior chemical properties and lower impurities, enhancing its economic value. Unrefined nickel, while less costly to produce, is often limited to applications with lower quality requirements, impacting its market demand and profitability.

Quality Standards and Regulatory Aspects

Refined nickel meets stringent quality standards, including ISO 9001 certification and compliance with ASTM B39 specifications, ensuring high purity levels typically above 99.8%, crucial for applications in aerospace and electronics. Unrefined nickel often contains higher levels of impurities such as sulfur and iron, limiting its use to less demanding industrial processes. Regulatory frameworks such as REACH in Europe and EPA guidelines in the US govern the environmental impact and safe handling of both refined and unrefined nickel, emphasizing traceability and emission controls.

Market Demand for Refined versus Unrefined Nickel

Refined nickel dominates market demand due to its higher purity and versatility in applications like stainless steel production and battery manufacturing for electric vehicles. Unrefined nickel, often used as feedstock for further processing, has limited direct industrial applications and faces lower market demand. The increasing shift toward clean energy technologies significantly boosts refined nickel's market value and demand worldwide.

Refined nickel vs Unrefined nickel Infographic

materialdif.com

materialdif.com