Nickel shot and nickel slug differ primarily in size and application within nickel plating processes. Nickel shot consists of small, rounded granules that melt quickly and provide uniform heating during plating, while nickel slug is a larger, solid piece that melts more slowly, offering a controlled deposition rate. Selecting between nickel shot and slug impacts plating quality, efficiency, and surface finish in nickel electroplating.

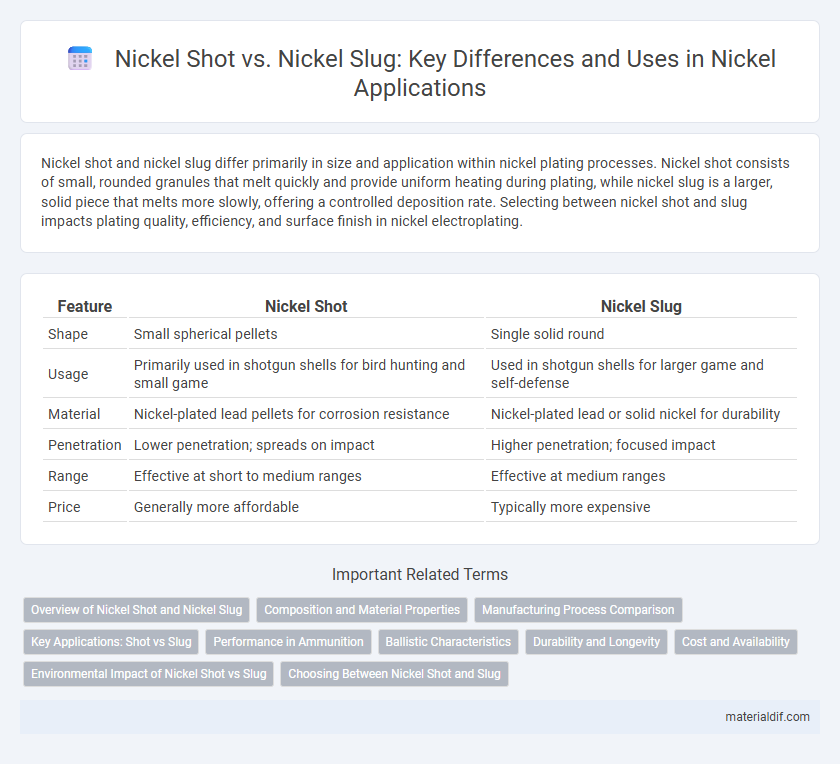

Table of Comparison

| Feature | Nickel Shot | Nickel Slug |

|---|---|---|

| Shape | Small spherical pellets | Single solid round |

| Usage | Primarily used in shotgun shells for bird hunting and small game | Used in shotgun shells for larger game and self-defense |

| Material | Nickel-plated lead pellets for corrosion resistance | Nickel-plated lead or solid nickel for durability |

| Penetration | Lower penetration; spreads on impact | Higher penetration; focused impact |

| Range | Effective at short to medium ranges | Effective at medium ranges |

| Price | Generally more affordable | Typically more expensive |

Overview of Nickel Shot and Nickel Slug

Nickel shot and nickel slug are both forms of nickel pellets used in plating and manufacturing, differing primarily in size and shape. Nickel shot consists of small, rounded particles with a smooth texture, providing consistent melting and easy handling in industrial applications. Nickel slug, however, features larger, cylindrical pieces that offer higher purity and are preferred for applications requiring precise control over nickel content and density.

Composition and Material Properties

Nickel shot consists of small, spherical nickel pellets commonly used for surface coating and metallurgy due to their consistent size and high purity, typically exceeding 99% nickel content. Nickel slug, on the other hand, refers to solid, cylindrical pieces of nickel metal produced by extrusion or casting, featuring excellent ductility and corrosion resistance ideal for precision manufacturing applications. The primary difference lies in their physical form and processing methods, which influence their suitability for various industrial uses, with shot favoring uniform melting and slugs supporting direct fabrication.

Manufacturing Process Comparison

Nickel shot consists of small, spherical granules produced by atomizing molten nickel, allowing rapid solidification and uniform particle size ideal for plating applications. In contrast, nickel slug manufacturing involves compressing and sintering nickel powder into dense, solid discs, offering higher density and structural integrity suitable for heavy-duty industrial use. The atomization process in nickel shot promotes faster electrolyte dissipation during electroplating, whereas the sintering process in nickel slugs enhances mechanical strength and conductivity in electronic components.

Key Applications: Shot vs Slug

Nickel shot is primarily used for surface finishing and plating processes, offering uniform coating and enhanced corrosion resistance in industries such as aerospace, automotive, and electronics. Nickel slug, formed by compacting and sintering nickel powders, is essential for manufacturing precision components in battery electrodes, fuel cells, and electrical contacts due to its high density and mechanical strength. The choice between nickel shot and slug depends on application requirements for coating uniformity versus structural integrity in high-performance engineering applications.

Performance in Ammunition

Nickel shot offers superior corrosion resistance and smoother feeding due to its uniform roundness, enhancing performance in shotgun ammunition. Nickel slug cartridges deliver higher accuracy and ballistic consistency, favored in hunting and tactical applications for precision. Both benefit from nickel plating, which extends barrel life and reduces fouling compared to traditional steel or lead alternatives.

Ballistic Characteristics

Nickel shot and nickel slug differ significantly in ballistic characteristics, with nickel shot consisting of small pellets that deliver widespread impact and reduced penetration, ideal for bird hunting and small game. Nickel slugs, being a single, large projectile, offer superior accuracy, greater kinetic energy, and deeper penetration, making them suitable for larger game and defensive use. The smooth nickel coating enhances corrosion resistance and barrel longevity for both types, but the slug's aerodynamics provide higher velocity retention and improved ballistic coefficient compared to the dispersed pellet pattern of shot.

Durability and Longevity

Nickel shot consists of small, irregular particles that provide quicker nickel ion release, leading to faster initial corrosion resistance but reduced long-term durability compared to nickel slug plating. Nickel slugs are solid, uniform pieces that offer superior longevity and enhanced wear resistance due to their consistent thickness and density, making them ideal for applications requiring extended protection. The dense structure of nickel slugs significantly prolongs the service life of coated components under harsh environmental conditions.

Cost and Availability

Nickel shot is generally more affordable and widely available due to its smaller particle size and ease of production, making it suitable for applications requiring quick melting and alloying. Nickel slug, being a solid cylindrical piece, typically costs more because of its higher material density and manufacturing complexity, which can limit its availability to specialized markets. For industries prioritizing cost efficiency and accessibility, nickel shot offers a more economical choice, while nickel slug is favored for precision applications despite its higher price point.

Environmental Impact of Nickel Shot vs Slug

Nickel shot, often used in industrial applications, typically consists of small, irregular granules that can disperse into the environment, raising concerns about soil and water contamination due to nickel's toxicity and bioaccumulation potential. Nickel slug, a solid cylindrical form, has a reduced surface area exposure which limits leaching and environmental dispersion, resulting in a lower ecological risk compared to nickel shot. Lifecycle analyses indicate that nickel slugs generate less environmental impact through reduced particulate emissions during handling and disposal.

Choosing Between Nickel Shot and Slug

Choosing between nickel shot and nickel slug depends on the intended application and desired performance. Nickel shot offers better coverage and penetration for bird hunting and small game due to its dispersed pattern, while nickel slugs provide higher accuracy and greater stopping power for larger game or self-defense. Understanding the ballistic differences and target requirements ensures optimal effectiveness when selecting nickel ammunition.

Nickel Shot vs Nickel Slug Infographic

materialdif.com

materialdif.com