High-nickel steel offers superior corrosion resistance and greater tensile strength compared to low-nickel steel, making it ideal for demanding environments and applications requiring durability. Low-nickel steel is more cost-effective and easier to weld, often used for general construction where high performance is less critical. Selecting between high-nickel and low-nickel steel depends on balancing budget constraints with the need for enhanced mechanical properties.

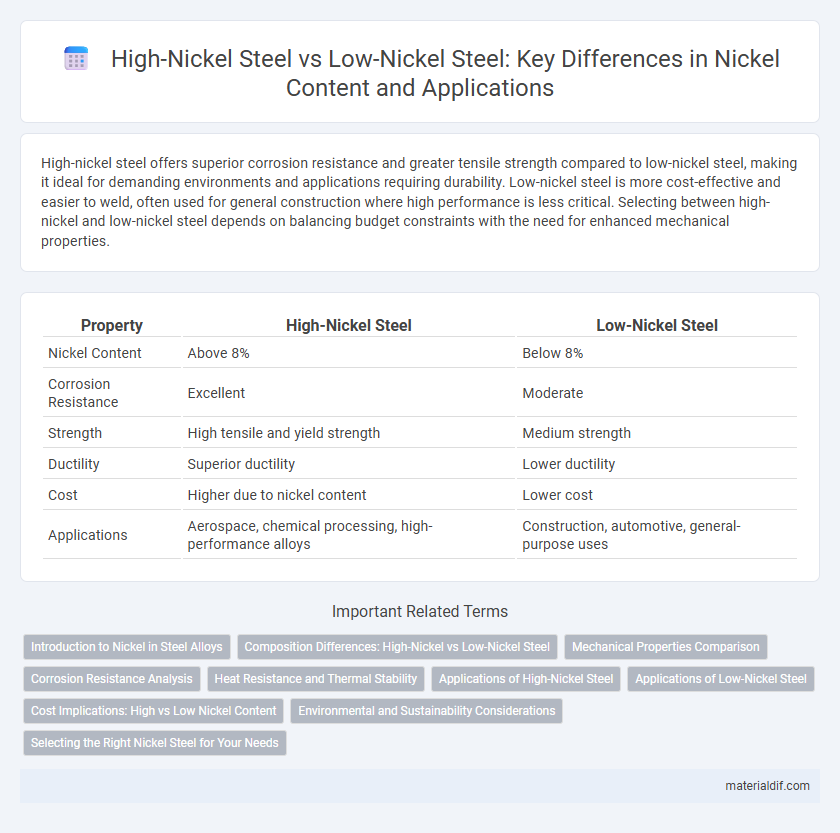

Table of Comparison

| Property | High-Nickel Steel | Low-Nickel Steel |

|---|---|---|

| Nickel Content | Above 8% | Below 8% |

| Corrosion Resistance | Excellent | Moderate |

| Strength | High tensile and yield strength | Medium strength |

| Ductility | Superior ductility | Lower ductility |

| Cost | Higher due to nickel content | Lower cost |

| Applications | Aerospace, chemical processing, high-performance alloys | Construction, automotive, general-purpose uses |

Introduction to Nickel in Steel Alloys

Nickel significantly enhances steel alloys by improving corrosion resistance, toughness, and strength, making high-nickel steel ideal for demanding applications like aerospace and chemical processing. High-nickel steel typically contains more than 8% nickel, providing superior durability and resistance to oxidation compared to low-nickel steel, which usually contains less than 4% nickel. The balance of nickel content directly influences the steel's microstructure, mechanical properties, and cost-effectiveness, guiding material selection based on performance requirements.

Composition Differences: High-Nickel vs Low-Nickel Steel

High-nickel steel typically contains more than 8% nickel, enhancing corrosion resistance, toughness, and strength, while low-nickel steel usually has less than 4% nickel content, prioritizing cost-effectiveness and magnetic properties. The increased nickel proportion in high-nickel steel stabilizes the austenitic microstructure, making it ideal for applications like aerospace and cryogenic environments. In contrast, low-nickel steel's reduced nickel content results in a ferritic or martensitic structure, suitable for structural components and general-purpose use.

Mechanical Properties Comparison

High-nickel steel exhibits superior tensile strength, enhanced corrosion resistance, and improved ductility compared to low-nickel steel, making it ideal for demanding mechanical applications. Low-nickel steel offers lower cost and good weldability but typically lacks the high-temperature stability and fatigue resistance found in high-nickel alloys. The increased nickel content in high-nickel steel significantly boosts toughness and elongation, which are critical for aerospace and chemical processing industries.

Corrosion Resistance Analysis

High-nickel steel demonstrates superior corrosion resistance compared to low-nickel steel due to its enhanced chromium-nickel matrix that forms a stable, passive oxide layer, preventing rust and oxidation. The elevated nickel content improves resistance against harsh environments, including marine and chemical exposure, minimizing pitting and crevice corrosion. Low-nickel steel, while more cost-effective, often lacks sufficient protective oxide formation, leading to increased vulnerability in corrosive atmospheres.

Heat Resistance and Thermal Stability

High-nickel steel exhibits superior heat resistance and thermal stability compared to low-nickel steel, maintaining structural integrity at temperatures exceeding 900degC due to its higher nickel content. The enhanced thermal stability results from nickel's ability to slow down grain growth and reduce oxidation rates during prolonged exposure to heat. Low-nickel steel, with less than 8% nickel, tends to undergo faster thermal degradation and reduced mechanical performance under high-temperature conditions.

Applications of High-Nickel Steel

High-nickel steel, containing typically above 8% nickel, excels in applications requiring exceptional corrosion resistance and high-temperature strength, such as aerospace components, chemical processing equipment, and marine environments. Its ability to maintain structural integrity under extreme conditions makes it ideal for turbine blades, jet engine parts, and cryogenic vessels. Low-nickel steel, with nickel content below 8%, is predominantly used in general construction and automotive industries where moderate performance and cost efficiency are prioritized.

Applications of Low-Nickel Steel

Low-nickel steel is extensively used in construction and automotive industries due to its cost-effectiveness and adequate corrosion resistance. Its applications include manufacturing structural components, machinery parts, and automotive body panels where high strength and moderate corrosion resistance are required. Low-nickel steel is preferred for large-scale infrastructure projects and consumer goods where budget constraints limit the use of high-nickel alloys.

Cost Implications: High vs Low Nickel Content

High-nickel steel typically incurs higher production costs due to the increased price and demand for nickel, impacting overall material expenses in industries such as aerospace and automotive manufacturing. Low-nickel steel offers a more cost-effective alternative, leveraging reduced nickel content to lower raw material costs while still maintaining sufficient corrosion resistance and mechanical properties for many applications. Cost implications vary significantly based on nickel market fluctuations, influencing the selection between high-nickel and low-nickel steel in large-scale production.

Environmental and Sustainability Considerations

High-nickel steel offers greater corrosion resistance and durability, reducing the frequency of replacements and associated resource consumption. Low-nickel steel demands less energy and raw materials during production, yielding a smaller carbon footprint and lower environmental impact. Selecting the appropriate nickel content depends on balancing lifecycle sustainability with performance requirements in specific applications.

Selecting the Right Nickel Steel for Your Needs

High-nickel steel offers superior corrosion resistance, enhanced mechanical strength, and excellent performance at elevated temperatures, making it ideal for aerospace, chemical processing, and marine applications. Low-nickel steel provides cost-effective durability and adequate resistance for everyday structural use, automotive parts, and general manufacturing where extreme conditions are less prevalent. Selecting the right nickel steel depends on balancing factors like corrosion resistance requirements, mechanical strength, operating environment, and budget constraints.

High-Nickel Steel vs Low-Nickel Steel Infographic

materialdif.com

materialdif.com