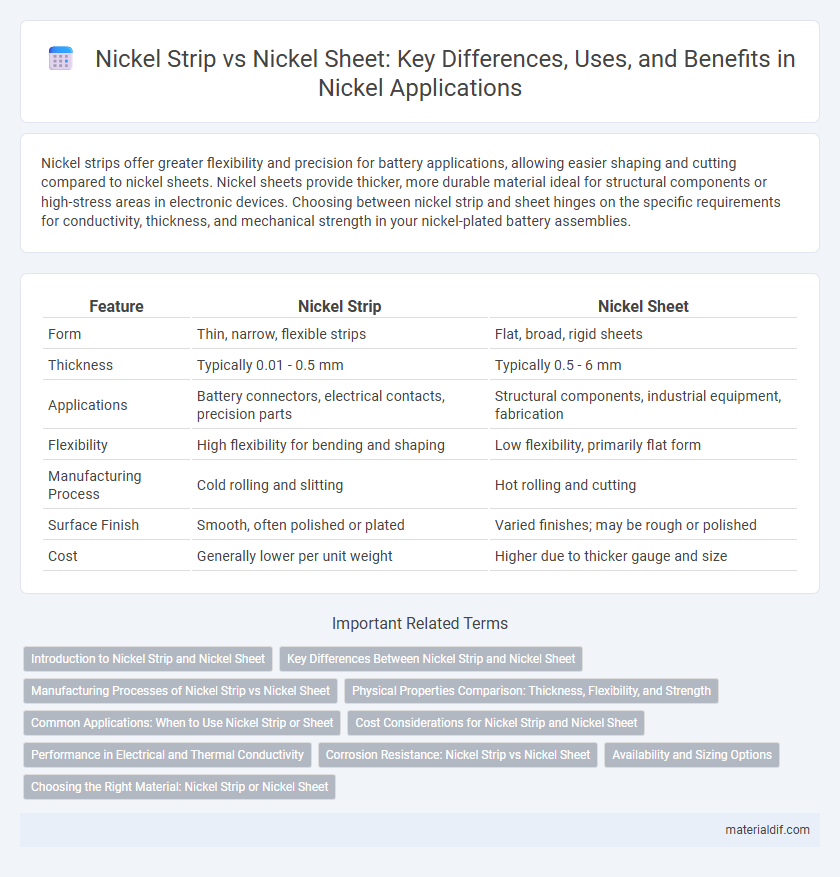

Nickel strips offer greater flexibility and precision for battery applications, allowing easier shaping and cutting compared to nickel sheets. Nickel sheets provide thicker, more durable material ideal for structural components or high-stress areas in electronic devices. Choosing between nickel strip and sheet hinges on the specific requirements for conductivity, thickness, and mechanical strength in your nickel-plated battery assemblies.

Table of Comparison

| Feature | Nickel Strip | Nickel Sheet |

|---|---|---|

| Form | Thin, narrow, flexible strips | Flat, broad, rigid sheets |

| Thickness | Typically 0.01 - 0.5 mm | Typically 0.5 - 6 mm |

| Applications | Battery connectors, electrical contacts, precision parts | Structural components, industrial equipment, fabrication |

| Flexibility | High flexibility for bending and shaping | Low flexibility, primarily flat form |

| Manufacturing Process | Cold rolling and slitting | Hot rolling and cutting |

| Surface Finish | Smooth, often polished or plated | Varied finishes; may be rough or polished |

| Cost | Generally lower per unit weight | Higher due to thicker gauge and size |

Introduction to Nickel Strip and Nickel Sheet

Nickel strip and nickel sheet are widely used forms of nickel metal in industrial applications, each offering distinct advantages in thickness and flexibility. Nickel strip, typically thinner and narrower, is preferred for precision components such as batteries and electronics, providing excellent conductivity and corrosion resistance. Nickel sheet, generally thicker and available in larger dimensions, is favored for structural applications, offering enhanced mechanical strength and ease of fabrication in manufacturing processes.

Key Differences Between Nickel Strip and Nickel Sheet

Nickel strip is typically thinner, more flexible, and used in applications requiring precision and conductivity, such as battery connectors and electronic components. Nickel sheet is thicker, rigid, and suited for structural or protective purposes in industrial machinery and corrosion-resistant surfaces. The key differences lie in their thickness, flexibility, and specific use cases related to conductivity versus structural integrity.

Manufacturing Processes of Nickel Strip vs Nickel Sheet

Nickel strip is typically produced through cold rolling, which involves repeatedly passing nickel ingots through rollers to achieve precise thickness and enhanced mechanical properties. In contrast, nickel sheet is often manufactured using hot rolling, where heated nickel slabs are rolled to form thicker, less refined sheets suitable for structural applications. The cold rolling process for nickel strips offers tighter dimensional tolerances and smoother surface finishes compared to the coarser texture and higher thickness of hot-rolled nickel sheets.

Physical Properties Comparison: Thickness, Flexibility, and Strength

Nickel strips typically feature thinner gauges ranging from 0.05mm to 0.3mm, offering enhanced flexibility for intricate applications, whereas nickel sheets are thicker, commonly between 0.3mm and 3mm, providing superior mechanical strength and rigidity. The higher thickness of nickel sheets results in increased tensile strength and durability, making them suitable for structural components, while nickel strips' flexibility allows easy bending without compromising conductive integrity. Both forms exhibit excellent corrosion resistance and thermal stability, but the choice hinges on balancing the required dimensional precision and mechanical robustness.

Common Applications: When to Use Nickel Strip or Sheet

Nickel strips are commonly used in battery manufacturing, electrical connectors, and welding applications due to their thin, flexible form that allows precise conductivity and easy shaping. Nickel sheets offer greater thickness and rigidity, making them ideal for structural components, heat exchangers, and corrosion-resistant surfaces in chemical processing equipment. Choosing between nickel strip and sheet depends on the application's mechanical strength requirements and electrical conductivity needs.

Cost Considerations for Nickel Strip and Nickel Sheet

Nickel strip typically costs more than nickel sheet due to its narrower width and higher production precision, which demand specialized rolling and slitting processes. Nickel sheet offers a more economical option for large surface area applications because it is produced in wider, bulk rolls with less processing complexity. When budgeting for projects, the choice between nickel strip and sheet hinges on the required dimensions, quantity, and tolerance specifications, with nickel sheet providing cost advantages in bulk purchases.

Performance in Electrical and Thermal Conductivity

Nickel strips offer superior electrical conductivity due to their thinner profile, enabling faster electron flow and efficient current distribution in electronic components. Nickel sheets, although thicker, provide enhanced thermal conductivity, allowing better heat dissipation in high-temperature applications. Choosing between nickel strip and sheet depends on balancing the need for electrical performance against thermal management requirements.

Corrosion Resistance: Nickel Strip vs Nickel Sheet

Nickel strip and nickel sheet both exhibit excellent corrosion resistance, but the strip's thinner profile allows for faster heat dissipation, reducing localized corrosion risks in high-temperature applications. Nickel sheets, being thicker, provide more uniform protection against corrosive environments, making them ideal for structural components exposed to harsh chemicals. The choice between nickel strip and nickel sheet depends on the specific corrosion resistance requirements and environmental conditions of the application.

Availability and Sizing Options

Nickel strips offer enhanced availability in thinner gauge options, catering to applications requiring flexibility and precision, while nickel sheets are generally available in thicker gauges suited for structural uses. Nickel strips typically come in narrower widths and longer lengths, providing greater versatility for detailed fabrication processes. In contrast, nickel sheets are offered in wider dimensions and standard sizes, making them ideal for larger-scale industrial applications.

Choosing the Right Material: Nickel Strip or Nickel Sheet

Selecting between nickel strip and nickel sheet depends on the application's requirements for thickness, flexibility, and surface area. Nickel strips, typically thinner and narrower, excel in electrical connectors and battery tabs due to their excellent conductivity and ease of bending. Nickel sheets offer greater structural strength and larger surface coverage, making them ideal for corrosion-resistant plating, fabrication, and industrial parts.

Nickel strip vs Nickel sheet Infographic

materialdif.com

materialdif.com