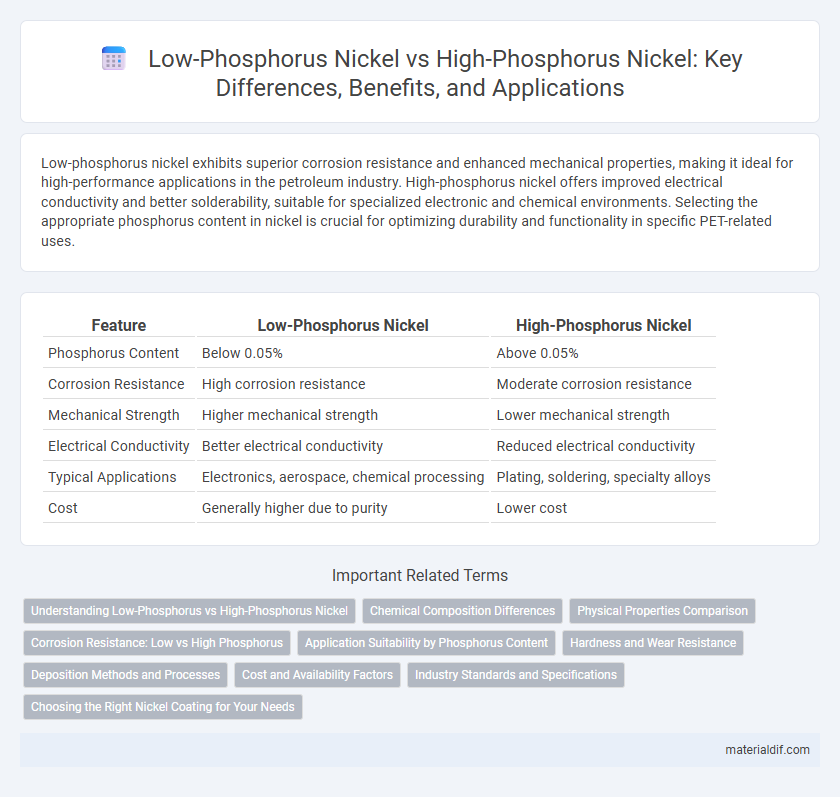

Low-phosphorus nickel exhibits superior corrosion resistance and enhanced mechanical properties, making it ideal for high-performance applications in the petroleum industry. High-phosphorus nickel offers improved electrical conductivity and better solderability, suitable for specialized electronic and chemical environments. Selecting the appropriate phosphorus content in nickel is crucial for optimizing durability and functionality in specific PET-related uses.

Table of Comparison

| Feature | Low-Phosphorus Nickel | High-Phosphorus Nickel |

|---|---|---|

| Phosphorus Content | Below 0.05% | Above 0.05% |

| Corrosion Resistance | High corrosion resistance | Moderate corrosion resistance |

| Mechanical Strength | Higher mechanical strength | Lower mechanical strength |

| Electrical Conductivity | Better electrical conductivity | Reduced electrical conductivity |

| Typical Applications | Electronics, aerospace, chemical processing | Plating, soldering, specialty alloys |

| Cost | Generally higher due to purity | Lower cost |

Understanding Low-Phosphorus vs High-Phosphorus Nickel

Low-phosphorus nickel contains less than 0.005% phosphorus, resulting in improved corrosion resistance and superior electrical conductivity, making it ideal for high-performance applications like aerospace and electronic components. High-phosphorus nickel, with phosphorus content above 0.1%, exhibits enhanced hardness and wear resistance but reduced ductility and weldability, often utilized in specialized plating and chemical processing equipment. Understanding the distinction between low-phosphorus and high-phosphorus nickel is crucial for selecting the appropriate grade based on mechanical properties and environmental resistance requirements.

Chemical Composition Differences

Low-phosphorus nickel contains less than 0.01% phosphorus, ensuring higher purity and superior corrosion resistance, making it ideal for chemical and electronic applications. In contrast, high-phosphorus nickel, with phosphorus content typically ranging from 0.04% to 0.12%, exhibits enhanced hardness and wear resistance but lower ductility. The chemical composition difference significantly influences the mechanical properties and suitability of nickel for specialized industrial uses.

Physical Properties Comparison

Low-phosphorus nickel exhibits superior corrosion resistance and enhanced ductility compared to high-phosphorus nickel, which tends to be harder and more brittle due to higher phosphorus content. The melting point of low-phosphorus nickel typically ranges around 1455degC, while high-phosphorus nickel may show slight variations influenced by impurity concentrations. Mechanical strength and electrical conductivity are generally better optimized in low-phosphorus nickel, making it preferable for applications requiring durability and conductivity.

Corrosion Resistance: Low vs High Phosphorus

Low-phosphorus nickel exhibits superior corrosion resistance in acidic environments due to its reduced phosphorus content, which minimizes the formation of brittle phases that can initiate corrosion. High-phosphorus nickel, while offering better resistance to hydrogen sulfide and stress corrosion cracking, tends to have lower general corrosion resistance in chloride-rich or oxidizing conditions. Selecting between low and high-phosphorus nickel depends on the specific industrial application and environmental exposure, with low-phosphorus variants preferred for robust corrosion protection in aggressive aqueous media.

Application Suitability by Phosphorus Content

Low-phosphorus nickel, with phosphorus content below 0.02%, is preferred for applications requiring high corrosion resistance and mechanical strength, such as aerospace and electronics manufacturing. High-phosphorus nickel, containing phosphorus levels above 0.05%, offers excellent catalytic properties and is widely used in chemical processing and hydrogenation reactions. The phosphorus content directly affects nickel's magnetic properties and weldability, determining its suitability for specific industrial applications.

Hardness and Wear Resistance

Low-phosphorus nickel exhibits superior hardness and enhanced wear resistance compared to high-phosphorus nickel due to its lower impurity content, which minimizes brittleness and improves structural integrity. High-phosphorus nickel tends to be softer and more ductile, making it less resistant to abrasive and erosive wear in demanding industrial applications. The optimized hardness and wear resistance of low-phosphorus nickel make it ideal for use in components subjected to high stress and friction.

Deposition Methods and Processes

Low-phosphorus nickel is typically deposited using chemical vapor deposition (CVD) or electroplating methods that allow precise control over phosphorus content, ensuring enhanced corrosion resistance and mechanical properties. High-phosphorus nickel is often produced by electrodeposition with higher phosphorus electrolyte concentrations, leading to a more amorphous structure that improves hardenability and wear resistance. Control of deposition parameters such as current density, temperature, and electrolyte composition is critical to tailor the microstructure and phosphorus content in nickel coatings.

Cost and Availability Factors

Low-phosphorus nickel generally offers higher cost efficiency due to its more straightforward refining process and widespread availability in major mining regions. High-phosphorus nickel incurs increased processing expenses to remove impurities, leading to higher overall production costs and limited supply from specialized sources. Market demand for low-phosphorus variants remains strong, driven by industries requiring high-purity metal for stainless steel and alloy production.

Industry Standards and Specifications

Low-phosphorus nickel is preferred in aerospace and electronics industries due to its superior corrosion resistance and adherence to ASTM B162 and AMS 4569 standards, which specify maximum phosphorus limits of 0.05%. High-phosphorus nickel, with phosphorus content exceeding 0.10%, is commonly used in chemical processing applications following ASTM B161 specifications, providing enhanced resistance to sulfuric acid corrosion. Industry specifications prioritize phosphorus levels to ensure optimal mechanical properties and corrosion resistance tailored to specific operational environments.

Choosing the Right Nickel Coating for Your Needs

Low-phosphorus nickel coatings offer superior corrosion resistance and ductility, making them ideal for aerospace and electronics applications where precision and durability are critical. High-phosphorus nickel coatings provide excellent chemical resistance and hardness, suited for harsh environments such as chemical processing and industrial machinery. Selecting between low- and high-phosphorus nickel depends on the specific performance requirements, including exposure to corrosive agents, mechanical stress, and desired surface finish.

Low-phosphorus nickel vs high-phosphorus nickel Infographic

materialdif.com

materialdif.com