Ferronickel contains a higher percentage of nickel, typically between 20% and 40%, making it ideal for stainless steel production due to its superior purity and strength. Nickel Pig Iron (NPI) is a lower-grade, cost-effective alternative with nickel content usually ranging from 4% to 13%, mainly used in industries where high purity is less critical. The choice between Ferronickel and NPI depends on the required nickel content, quality standards, and economic considerations in metal manufacturing.

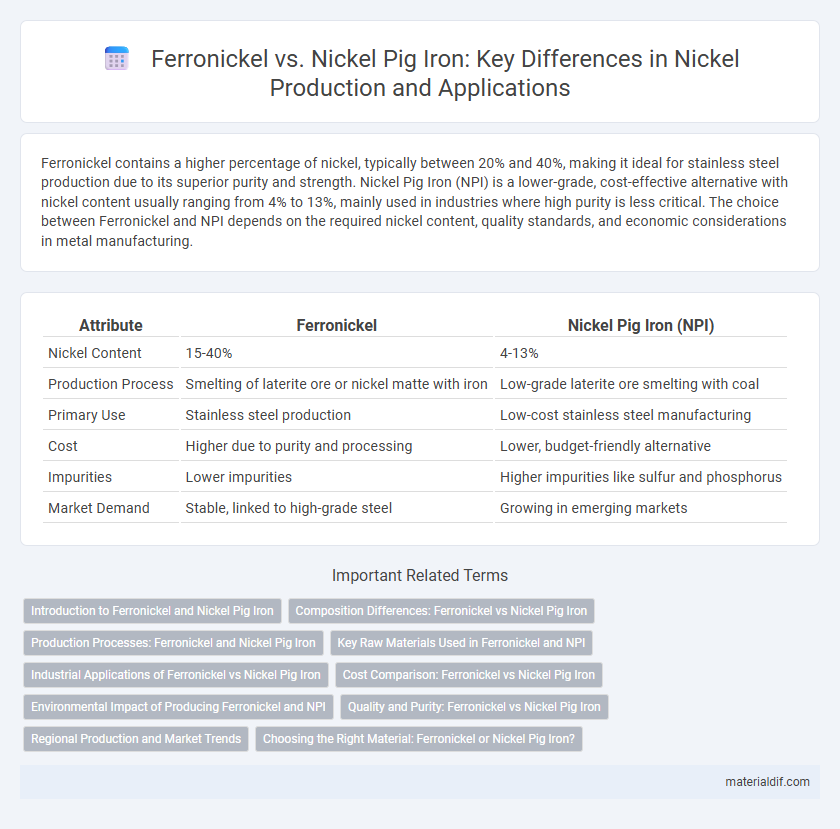

Table of Comparison

| Attribute | Ferronickel | Nickel Pig Iron (NPI) |

|---|---|---|

| Nickel Content | 15-40% | 4-13% |

| Production Process | Smelting of laterite ore or nickel matte with iron | Low-grade laterite ore smelting with coal |

| Primary Use | Stainless steel production | Low-cost stainless steel manufacturing |

| Cost | Higher due to purity and processing | Lower, budget-friendly alternative |

| Impurities | Lower impurities | Higher impurities like sulfur and phosphorus |

| Market Demand | Stable, linked to high-grade steel | Growing in emerging markets |

Introduction to Ferronickel and Nickel Pig Iron

Ferronickel is an alloy primarily composed of iron and nickel, commonly used in stainless steel manufacturing due to its high nickel content and cost-effectiveness. Nickel Pig Iron (NPI) is a low-grade ferronickel substitute, produced from laterite nickel ore through smelting, and mainly utilized by the Chinese steel industry to meet growing nickel demand at lower prices. The key differences lie in their nickel content, production methods, and industrial applications, with Ferronickel offering higher purity and Nickel Pig Iron providing a more affordable alternative.

Composition Differences: Ferronickel vs Nickel Pig Iron

Ferronickel typically contains 20-40% nickel combined with iron and small amounts of carbon and other impurities, resulting in a higher purity alloy used mainly in stainless steel production. Nickel pig iron (NPI) usually has a lower nickel content, around 4-13%, with higher levels of carbon and impurities such as sulfur and phosphorus, making it a cheaper, lower-grade raw material for steel manufacturing. The composition differences influence their respective applications and pricing, with ferronickel preferred for high-quality steel and NPI suited for bulk industrial use.

Production Processes: Ferronickel and Nickel Pig Iron

Ferronickel production involves the smelting of laterite ores in electric arc furnaces, using a controlled process to yield a high-nickel alloy primarily composed of iron and nickel. Nickel Pig Iron is produced by directly smelting low-grade nickel laterite ores in blast furnaces or electric furnaces, resulting in a lower purity product with higher impurities. The Ferronickel process is energy-intensive but produces higher-grade material suitable for stainless steel manufacturing, while Nickel Pig Iron offers a cost-effective alternative for stainless steel producers with lower nickel content requirements.

Key Raw Materials Used in Ferronickel and NPI

Ferronickel primarily uses laterite nickel ore, combining nickel with iron in smelting processes to produce an alloy with typically 20-40% nickel content. Nickel Pig Iron (NPI) relies on low-grade nickel laterite ores and often includes impurities due to less refined smelting methods, resulting in lower nickel purity around 4-13%. Key raw materials for ferronickel involve higher-grade laterite ores and fluxes, while NPI production frequently incorporates low-grade ore mixed with coal and limestone to reduce costs.

Industrial Applications of Ferronickel vs Nickel Pig Iron

Ferronickel and nickel pig iron serve distinct industrial applications based on their composition and purity levels; ferronickel, with its higher nickel content and lower impurities, is predominantly used in stainless steel production requiring superior corrosion resistance and mechanical properties. Nickel pig iron, being a low-grade and cost-effective alternative, is widely utilized in the manufacturing of basic stainless steel and alloy steels where less stringent quality is acceptable. Industries prioritize ferronickel for high-performance alloys, while nickel pig iron supports large-scale, economical steel production.

Cost Comparison: Ferronickel vs Nickel Pig Iron

Ferronickel generally has higher production costs than Nickel Pig Iron due to more complex smelting processes and higher energy consumption. Nickel Pig Iron is cheaper because it uses lower-grade laterite ores and simpler production methods, making it a cost-effective alternative in stainless steel manufacturing. Cost efficiency of Nickel Pig Iron is driving its increased use in markets where budget constraints are significant.

Environmental Impact of Producing Ferronickel and NPI

Producing ferronickel typically results in lower greenhouse gas emissions compared to Nickel Pig Iron (NPI) due to more efficient smelting technologies and higher nickel content in the raw materials, reducing energy consumption per unit of metal produced. NPI production often involves the direct reduction of laterite ores in electric furnaces with significant coal usage, leading to higher carbon footprint and greater atmospheric pollution, including sulfur dioxide and particulate matter emissions. Sustainable practices in ferronickel production, such as waste gas recycling and slag reutilization, further mitigate environmental impact compared to the generally higher waste generation and ecological disruption associated with NPI manufacturing.

Quality and Purity: Ferronickel vs Nickel Pig Iron

Ferronickel contains higher nickel content, typically ranging from 20% to 40%, resulting in superior quality and purity compared to Nickel Pig Iron (NPI), which usually has nickel content between 4% and 13%. The production process of Ferronickel involves smelting lateritic nickel ores with iron, yielding a more refined alloy with fewer impurities, while NPI is produced from low-grade ores with minimal refining, leading to higher levels of impurities such as sulfur and phosphorus. Consequently, Ferronickel is preferred in high-grade stainless steel manufacturing due to its consistent quality and purity, whereas NPI is commonly used in lower-grade steel production where cost efficiency is prioritized.

Regional Production and Market Trends

Ferronickel production dominates in countries with abundant limonite nickel ore, such as the Philippines and New Caledonia, while Nickel Pig Iron (NPI) is primarily produced in China due to its vast laterite nickel deposits and lower processing costs. Market trends reveal that Ferronickel maintains a stable demand in stainless steel industries requiring higher purity, whereas NPI sees fluctuating demand influenced by China's domestic stainless steel production and global nickel price volatility. Regional supply dynamics and environmental regulations increasingly impact both production methods, with China's push for cleaner technology favoring Ferronickel's controlled smelting processes over NPI's energy-intensive operations.

Choosing the Right Material: Ferronickel or Nickel Pig Iron?

Ferronickel offers higher nickel content, typically ranging from 20% to 40%, making it ideal for producing stainless steel with improved corrosion resistance and mechanical properties. Nickel Pig Iron (NPI), containing around 4% to 13% nickel, provides a cost-effective alternative due to lower production expenses and suitability for large-scale steel manufacturing. Selecting between Ferronickel and NPI depends on the required nickel purity, application performance standards, and overall budget constraints in stainless steel production.

Ferronickel vs Nickel Pig Iron Infographic

materialdif.com

materialdif.com