Nickel metal hydride (NiMH) batteries offer higher energy density and longer cycle life compared to nickel-cadmium (NiCd) batteries, making them a more environmentally friendly choice due to reduced cadmium toxicity. While NiCd batteries excel in high-drain applications and extreme temperature performance, their memory effect and environmental hazards limit their widespread use today. Advances in nickel-based battery technology prioritize NiMH for everyday consumer electronics, balancing power, sustainability, and cost.

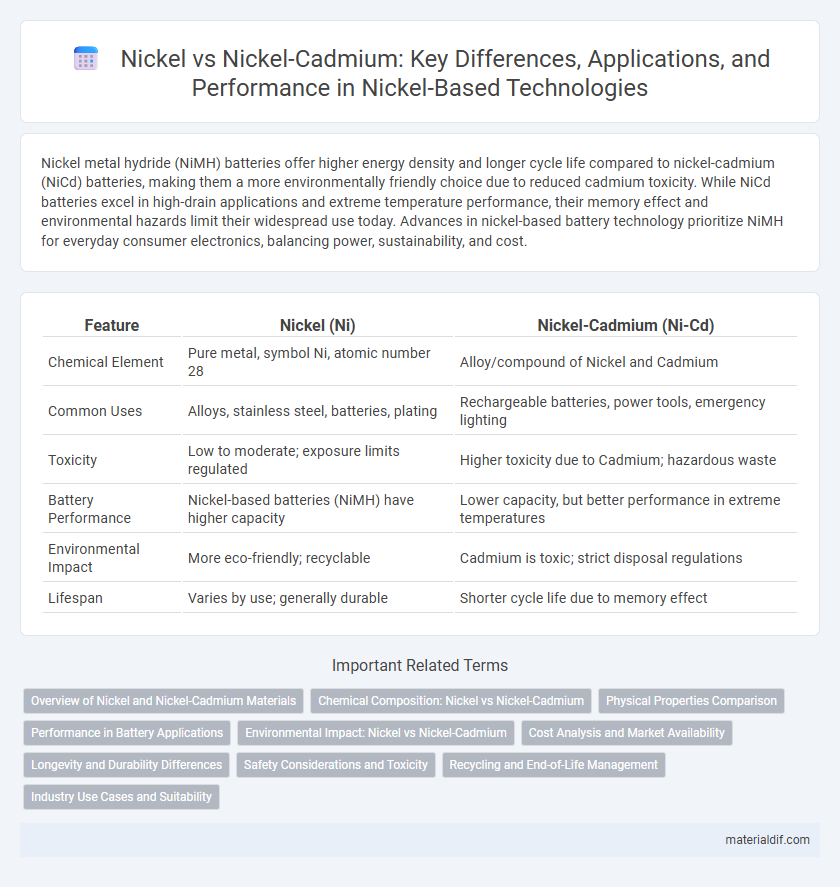

Table of Comparison

| Feature | Nickel (Ni) | Nickel-Cadmium (Ni-Cd) |

|---|---|---|

| Chemical Element | Pure metal, symbol Ni, atomic number 28 | Alloy/compound of Nickel and Cadmium |

| Common Uses | Alloys, stainless steel, batteries, plating | Rechargeable batteries, power tools, emergency lighting |

| Toxicity | Low to moderate; exposure limits regulated | Higher toxicity due to Cadmium; hazardous waste |

| Battery Performance | Nickel-based batteries (NiMH) have higher capacity | Lower capacity, but better performance in extreme temperatures |

| Environmental Impact | More eco-friendly; recyclable | Cadmium is toxic; strict disposal regulations |

| Lifespan | Varies by use; generally durable | Shorter cycle life due to memory effect |

Overview of Nickel and Nickel-Cadmium Materials

Nickel is a versatile transition metal known for its corrosion resistance, thermal stability, and high conductivity, widely used in stainless steel production and electroplating. Nickel-Cadmium (Ni-Cd) batteries incorporate nickel and cadmium as electrodes, offering reliable rechargeable energy storage with robust cycle life and resistance to deep discharge. While pure nickel serves primarily in structural and alloy applications, Ni-Cd materials emphasize electrochemical energy efficiency and durability in portable electronics.

Chemical Composition: Nickel vs Nickel-Cadmium

Nickel consists primarily of the element nickel (Ni), known for its corrosion resistance and high melting point of 1455degC, whereas nickel-cadmium (Ni-Cd) is an alloy combining nickel and cadmium (Cd), which imparts improved battery electrode properties due to cadmium's electrochemical stability. The chemical composition of Ni-Cd typically contains about 45-65% nickel and 30-50% cadmium, creating a material favored in rechargeable battery applications for its robust cycle life and resistance to electrolyte corrosion. Pure nickel's simpler elemental structure contrasts with the more complex alloy matrix of nickel-cadmium, influencing their respective industrial uses and environmental considerations.

Physical Properties Comparison

Nickel exhibits superior corrosion resistance and a higher melting point of 1455degC compared to the melting point of nickel-cadmium alloys, typically around 1350degC, making it more suitable for high-temperature applications. Pure nickel's density is approximately 8.9 g/cm3, while nickel-cadmium alloys show slightly lower density due to cadmium's lighter atomic weight. Nickel also offers better electrical conductivity and mechanical strength than nickel-cadmium, which tends to be more brittle and less ductile.

Performance in Battery Applications

Nickel-metal hydride (NiMH) batteries offer higher energy density and improved cycle life compared to nickel-cadmium (NiCd) batteries, making them better suited for high-performance applications. NiMH batteries exhibit less memory effect and lower toxicity, enhancing safety and environmental compatibility. Despite NiCd's superior discharge rate and durability in extreme conditions, NiMH is generally preferred for consumer electronics due to its overall performance advantages.

Environmental Impact: Nickel vs Nickel-Cadmium

Nickel-cadmium (NiCd) batteries contain toxic cadmium, a heavy metal with severe environmental hazards, including soil and water contamination. In contrast, pure nickel-based batteries, such as nickel-metal hydride (NiMH), offer a more eco-friendly alternative with lower toxicity and improved recyclability. Choosing nickel over nickel-cadmium reduces hazardous waste and supports sustainable battery disposal and recycling practices.

Cost Analysis and Market Availability

Nickel metal generally offers a lower initial cost compared to nickel-cadmium (NiCd) batteries due to simpler production processes and reduced use of scarce materials like cadmium. Market availability favors nickel-based products as they are widely produced and supported by extensive supply chains, while NiCd batteries face restrictions due to environmental regulations limiting cadmium usage. Cost analysis reveals nickel alternatives benefit from economies of scale, contributing to broader adoption in consumer electronics and renewable energy storage markets.

Longevity and Durability Differences

Nickel-metal hydride (NiMH) batteries generally offer longer cycle life and improved durability compared to nickel-cadmium (NiCd) batteries, making them more suitable for applications requiring extended use. NiCd batteries are prone to memory effect, which can reduce their effective capacity and lifespan, whereas NiMH cells exhibit less memory degradation and maintain performance over numerous charge-discharge cycles. The environmental impact of NiMH is also lower due to the toxic nature of cadmium, increasing the preference for NiMH in consumer electronics and hybrid vehicles.

Safety Considerations and Toxicity

Nickel-Cadmium (NiCd) batteries pose higher toxicity risks due to cadmium, a known carcinogen causing environmental and health hazards during disposal or leakage. In contrast, pure nickel batteries, such as Nickel-Metal Hydride (NiMH), offer improved safety with significantly lower toxic metal content, reducing harmful exposure. Proper handling and recycling protocols remain essential for both battery types to mitigate potential environmental contamination and human health risks.

Recycling and End-of-Life Management

Nickel plays a critical role in recycling processes, especially when comparing pure nickel to nickel-cadmium (Ni-Cd) batteries, where nickel recovery rates can reach up to 90%. End-of-life management of Ni-Cd batteries is more complex due to the toxic cadmium content, necessitating specialized recycling facilities to prevent environmental contamination. Efficient recycling of nickel from Ni-Cd batteries supports resource conservation, reduces hazardous waste, and promotes sustainable metal reuse in industrial applications.

Industry Use Cases and Suitability

Nickel is widely used in stainless steel production and electroplating, offering excellent corrosion resistance and durability for industrial applications. Nickel-cadmium (NiCd) batteries provide reliable performance in extreme temperatures and high-discharge scenarios, making them suitable for aerospace, emergency lighting, and power tools. While pure nickel excels in structural and surface applications, nickel-cadmium is preferred for rechargeable energy storage due to its consistent cycle life and robustness.

Nickel vs Nickel-Cadmium Infographic

materialdif.com

materialdif.com