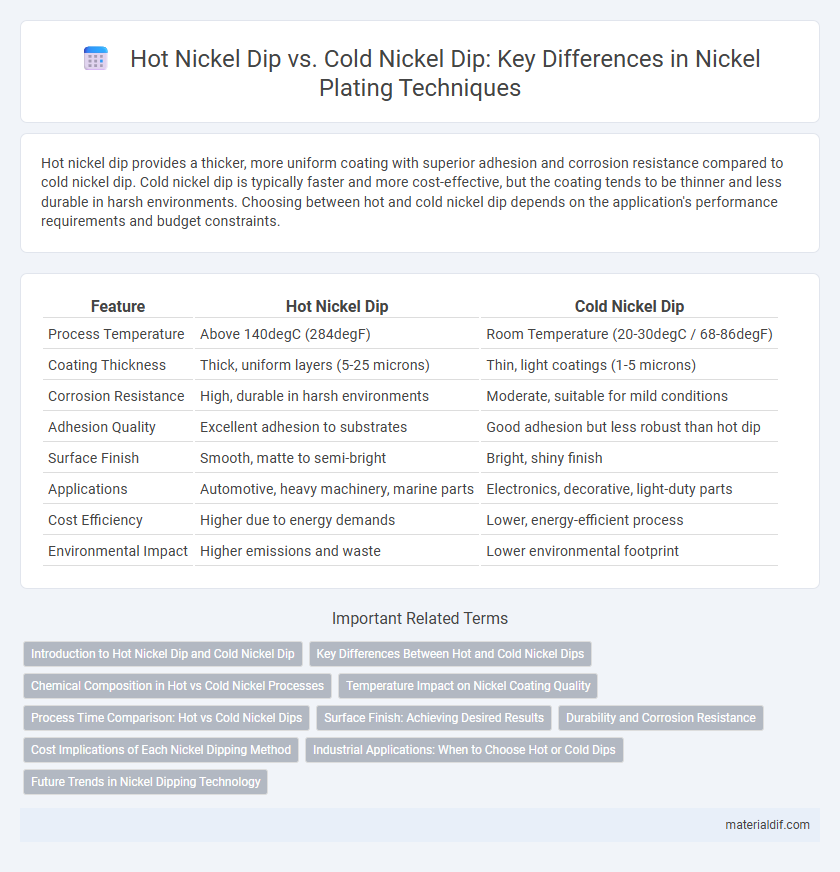

Hot nickel dip provides a thicker, more uniform coating with superior adhesion and corrosion resistance compared to cold nickel dip. Cold nickel dip is typically faster and more cost-effective, but the coating tends to be thinner and less durable in harsh environments. Choosing between hot and cold nickel dip depends on the application's performance requirements and budget constraints.

Table of Comparison

| Feature | Hot Nickel Dip | Cold Nickel Dip |

|---|---|---|

| Process Temperature | Above 140degC (284degF) | Room Temperature (20-30degC / 68-86degF) |

| Coating Thickness | Thick, uniform layers (5-25 microns) | Thin, light coatings (1-5 microns) |

| Corrosion Resistance | High, durable in harsh environments | Moderate, suitable for mild conditions |

| Adhesion Quality | Excellent adhesion to substrates | Good adhesion but less robust than hot dip |

| Surface Finish | Smooth, matte to semi-bright | Bright, shiny finish |

| Applications | Automotive, heavy machinery, marine parts | Electronics, decorative, light-duty parts |

| Cost Efficiency | Higher due to energy demands | Lower, energy-efficient process |

| Environmental Impact | Higher emissions and waste | Lower environmental footprint |

Introduction to Hot Nickel Dip and Cold Nickel Dip

Hot nickel dip involves immersing metal objects in a molten nickel bath at temperatures typically between 840degF and 900degF, creating a durable, corrosion-resistant coating through metallurgical bonding. Cold nickel dip, also known as electroless nickel plating, deposits nickel at lower temperatures around 190degF to 200degF using a chemical reduction process, resulting in a uniform, high-precision coating that enhances wear and corrosion resistance. Both processes serve critical roles in industrial applications, with hot nickel dip favoring thicker, tougher layers and cold nickel dip providing fine, controlled finishes.

Key Differences Between Hot and Cold Nickel Dips

Hot nickel dip utilizes elevated temperatures, typically around 60-80degC, to improve nickel ion diffusion and achieve a denser, more uniform coating with enhanced hardness and corrosion resistance. Cold nickel dip operates at room temperature, making it suitable for delicate substrates but often results in a thinner, less robust layer with lower wear resistance. The thermal activation in hot nickel plating facilitates faster deposition rates and better adhesion compared to the slower, less intense process of cold dipping.

Chemical Composition in Hot vs Cold Nickel Processes

Hot nickel dip processes utilize a high-temperature nickel plating bath, typically containing nickel sulfate, chloride, and boric acid, enhancing nickel ion deposition and resulting in a dense, uniform coating with superior adhesion. Cold nickel dip processes operate at lower temperatures with modified chemical compositions, often incorporating brighteners and organic additives to control plating quality and achieve smoother finishes, though with lower deposition rates. The elevated temperature in hot dips accelerates nickel ion diffusion, promoting a harder and more corrosion-resistant layer, while cold dips emphasize surface aesthetics and thickness control through chemical modulation.

Temperature Impact on Nickel Coating Quality

Hot nickel dip processes typically operate at temperatures around 144-149degC, promoting faster deposition rates and creating a dense, uniform nickel coating with enhanced corrosion resistance and hardness. Cold nickel dip plating occurs near room temperature, resulting in thinner coatings with less adhesion and increased porosity, negatively affecting durability and wear resistance. Temperature directly influences the microstructure and crystallinity of the nickel layer, making hot dips more suitable for high-performance protective finishes.

Process Time Comparison: Hot vs Cold Nickel Dips

Hot nickel dip processes typically require shorter immersion times, often ranging from 10 to 30 seconds, due to the elevated temperatures that accelerate the nickel deposition and improve coating adhesion. Cold nickel dip baths, operating at room temperature, generally necessitate longer immersion times, sometimes up to several minutes, to achieve a comparable coating thickness and quality. The faster processing time of hot nickel dipping enhances production efficiency, while cold nickel dipping offers better control over deposit properties in delicate or heat-sensitive applications.

Surface Finish: Achieving Desired Results

Hot nickel dip produces a smoother, more uniform surface finish due to the elevated temperature facilitating better fluidity and adhesion of the nickel coating. Cold nickel dip often results in a rougher texture with less consistent coverage, making it suitable for applications where surface finish quality is less critical. Selecting hot or cold nickel dip depends on the required surface finish, with hot dip optimizing corrosion resistance and aesthetic appeal.

Durability and Corrosion Resistance

Hot nickel dip offers superior durability and corrosion resistance compared to cold nickel dip due to its higher application temperature, which ensures better adhesion and a more uniform coating. The elevated heat in hot nickel dipping promotes diffusion between the nickel layer and the substrate, resulting in enhanced hardness and resistance to wear. Cold nickel dip, while easier to apply, generally provides a thinner, less resilient layer that is more susceptible to corrosion and mechanical damage over time.

Cost Implications of Each Nickel Dipping Method

Hot nickel dip involves immersing components in a heated nickel solution, resulting in faster deposition rates and improved adhesion, but it requires higher energy consumption and specialized equipment, leading to increased operational costs. Cold nickel dip, using room temperature baths, offers lower initial setup and energy expenses but yields slower plating with potentially less uniform coatings, which may increase maintenance and replacement costs over time. Choosing between hot and cold nickel dipping methods depends on balancing the upfront investment against long-term durability and performance requirements.

Industrial Applications: When to Choose Hot or Cold Dips

Hot nickel dip plating offers superior corrosion resistance and hardness, making it ideal for heavy-duty industrial components like automotive parts and cutting tools exposed to high temperatures and wear. Cold nickel dips are preferred for delicate electronic components and decorative finishes where moderate corrosion protection and precise thickness control are essential. Selecting between hot and cold nickel dips depends on the required durability, operating environment, and application-specific performance standards.

Future Trends in Nickel Dipping Technology

Emerging advancements in nickel dipping technology emphasize precise temperature control to enhance coating uniformity and adhesion, with hot nickel dip methods improving corrosion resistance while cold nickel dips reduce energy consumption and environmental impact. Innovations in alloy formulations and nanoparticle-enhanced baths are driving future trends by optimizing deposit quality and functional properties for industrial applications. Sustainable practices and automation integration are expected to accelerate the adoption of cold nickel dip processes, balancing performance with eco-friendly manufacturing demands.

Hot Nickel Dip vs Cold Nickel Dip Infographic

materialdif.com

materialdif.com