Refined nickel is produced through the purification of primary nickel, which is extracted directly from ore. Primary nickel contains impurities and requires extensive processing to achieve the high purity levels needed for industrial applications. Refined nickel offers superior quality and consistency, making it essential for advanced manufacturing and high-performance uses.

Table of Comparison

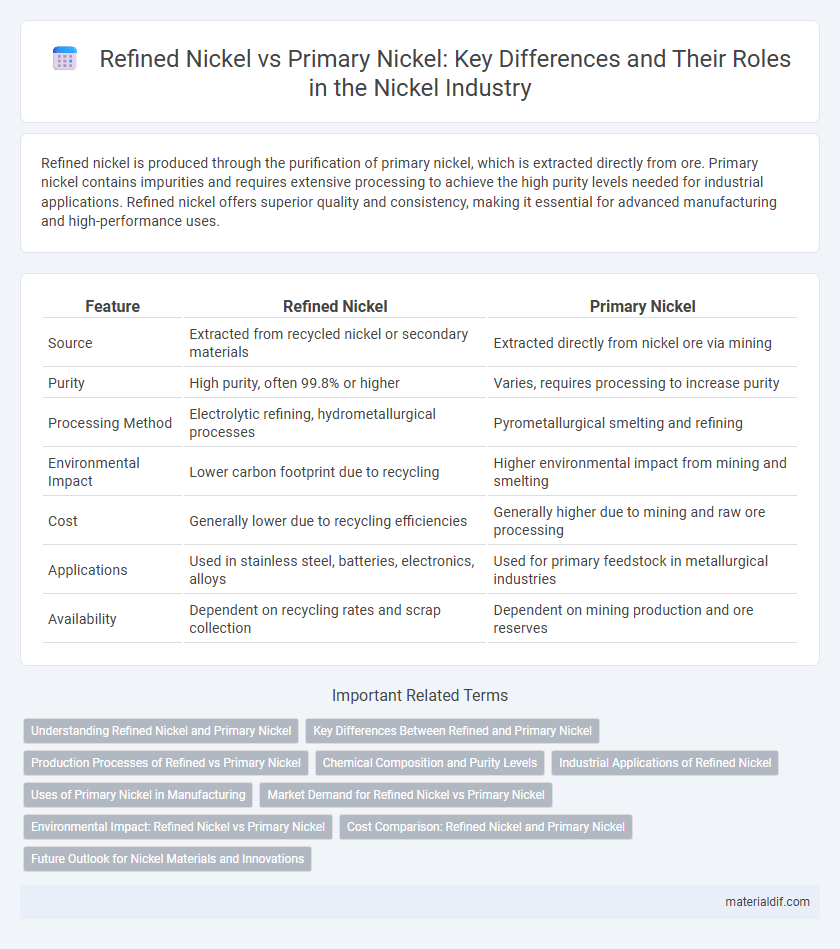

| Feature | Refined Nickel | Primary Nickel |

|---|---|---|

| Source | Extracted from recycled nickel or secondary materials | Extracted directly from nickel ore via mining |

| Purity | High purity, often 99.8% or higher | Varies, requires processing to increase purity |

| Processing Method | Electrolytic refining, hydrometallurgical processes | Pyrometallurgical smelting and refining |

| Environmental Impact | Lower carbon footprint due to recycling | Higher environmental impact from mining and smelting |

| Cost | Generally lower due to recycling efficiencies | Generally higher due to mining and raw ore processing |

| Applications | Used in stainless steel, batteries, electronics, alloys | Used for primary feedstock in metallurgical industries |

| Availability | Dependent on recycling rates and scrap collection | Dependent on mining production and ore reserves |

Understanding Refined Nickel and Primary Nickel

Refined nickel refers to nickel that has undergone extensive processing to achieve high purity levels, typically above 99.8%, making it suitable for industrial applications such as stainless steel production and battery manufacturing. Primary nickel, on the other hand, is nickel extracted directly from ore through mining and initial processing, representing the raw, unrefined form of the metal. Understanding the distinction between refined and primary nickel is crucial for industries relying on specific purity standards and defines the supply chain stages from ore extraction to final product manufacturing.

Key Differences Between Refined and Primary Nickel

Refined nickel is produced through smelting and purification processes that enhance its purity and suitability for industrial applications, typically exceeding 99% nickel content. Primary nickel, on the other hand, refers to nickel extracted directly from ore during mining, containing various impurities and often existing as sulfide or laterite ores. The key differences lie in purity levels, production methods, and end-use applications, with refined nickel being critical in battery manufacturing and stainless steel production, while primary nickel emphasizes resource extraction and initial processing stages.

Production Processes of Refined vs Primary Nickel

Refined nickel is produced through advanced metallurgical processes such as solvent extraction, electrowinning, and hydrometallurgical refining, yielding high-purity nickel suitable for batteries and electronics. Primary nickel is extracted directly from mineral ores like laterite and sulfide deposits via pyrometallurgical techniques including roasting, smelting, and converting, which produce intermediate products for further refining. The distinction lies in refined nickel undergoing additional purification steps to achieve superior chemical composition and performance standards.

Chemical Composition and Purity Levels

Refined nickel typically exhibits a purity level of 99.8% or higher, primarily consisting of nickel (Ni) with minimal impurities such as iron, cobalt, and copper, making it suitable for high-precision industrial applications. Primary nickel, extracted directly from ore, contains a broader spectrum of chemical elements including iron, sulfur, and other metals, reflecting lower purity that necessitates further refining to meet industry standards. The chemical composition differences between refined and primary nickel heavily influence their usability in sectors like stainless steel production and battery manufacturing.

Industrial Applications of Refined Nickel

Refined nickel, characterized by its high purity and low impurity levels, plays a crucial role in industrial applications such as stainless steel production, aerospace alloys, and electroplating due to its superior corrosion resistance and strength. Unlike primary nickel, which includes laterite and sulfide ore extractions, refined nickel undergoes extensive purification processes to meet stringent quality standards required in advanced manufacturing sectors. The enhanced properties of refined nickel make it indispensable for producing high-performance components in chemical processing equipment, power generation, and battery technologies.

Uses of Primary Nickel in Manufacturing

Primary nickel, extracted directly from ore, is essential in manufacturing stainless steel, corrosion-resistant alloys, and high-performance batteries and electronics. Its high purity and consistent quality enhance the durability and heat resistance of industrial equipment and aerospace components. The unique properties of primary nickel enable the production of specialty steels and superalloys crucial for automotive, energy, and chemical processing industries.

Market Demand for Refined Nickel vs Primary Nickel

Market demand for refined nickel is driven by its essential role in stainless steel production and battery manufacturing for electric vehicles, where high purity levels are critical. Primary nickel, extracted directly from ore through mining, serves as the raw material input but has lower immediate market appeal compared to the value-added refined nickel. Increasing global focus on clean energy and electric mobility significantly amplifies demand for refined nickel due to its superior quality for advanced applications.

Environmental Impact: Refined Nickel vs Primary Nickel

Refined nickel typically has a lower environmental impact compared to primary nickel because it is produced from recycled materials, reducing the need for energy-intensive mining and minimizing waste generation. Primary nickel extraction involves extensive mining processes that contribute to habitat destruction, high greenhouse gas emissions, and significant water pollution. The shift towards refined nickel supports sustainable practices by conserving natural resources and lowering the carbon footprint associated with nickel production.

Cost Comparison: Refined Nickel and Primary Nickel

Refined nickel generally incurs higher production costs due to energy-intensive refining processes and stringent purity standards, whereas primary nickel, typically extracted from laterite or sulfide ores, has lower upfront mining expenses but requires extensive processing to reach market specifications. The cost difference is influenced by factors such as ore grade, processing technology, and scale of production, with refined nickel often commanding premium prices in stainless steel and battery markets. Market fluctuations in raw material availability and energy prices further impact the comparative cost efficiency between refined and primary nickel sources.

Future Outlook for Nickel Materials and Innovations

Refined nickel is produced through advanced smelting and refining technologies, resulting in high purity suitable for battery-grade cathodes and emerging clean energy applications. Primary nickel, derived directly from ore extraction, remains essential but faces challenges due to environmental regulations and resource scarcity. Innovations in recycling, bioleaching, and low-carbon processing are set to enhance the sustainability and supply stability of nickel materials, driving growth in electric vehicle batteries and energy storage systems.

Refined Nickel vs Primary Nickel Infographic

materialdif.com

materialdif.com