Watts nickel bath offers excellent corrosion resistance and is widely used for decorative plating due to its bright, hard finish and good leveling properties. Sulfamate nickel bath, in contrast, provides superior ductility and is preferred for engineering applications requiring thicker, stress-free deposits with minimal internal stress. Choosing between Watts and sulfamate nickel baths depends on whether the priority is aesthetic appearance or functional mechanical performance.

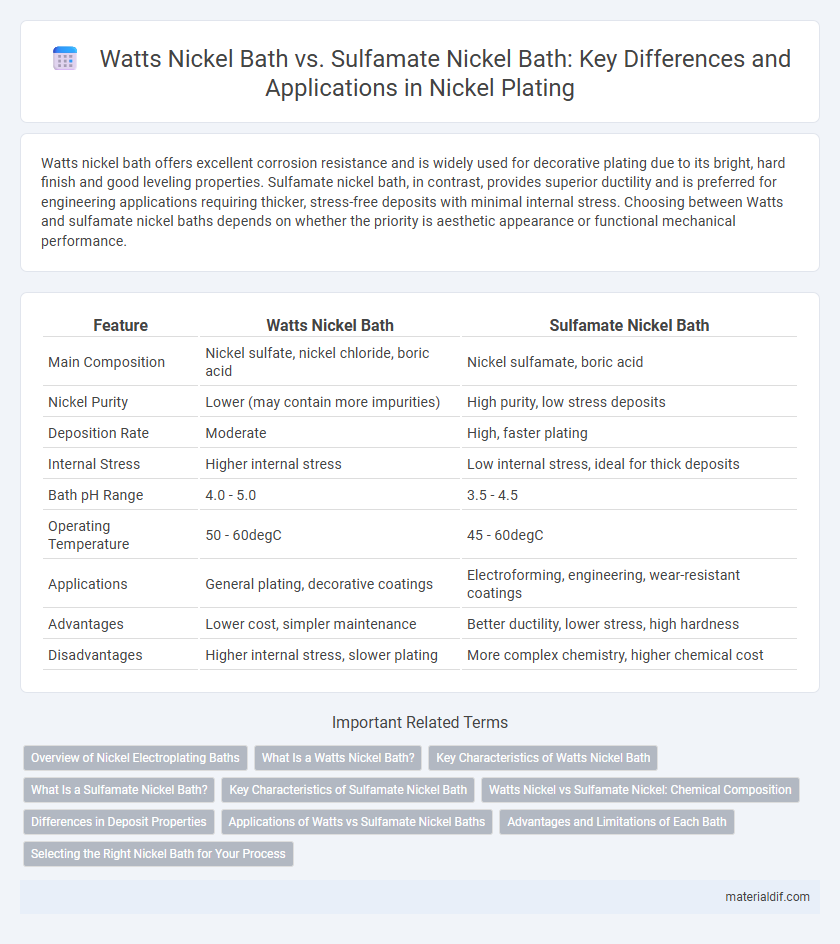

Table of Comparison

| Feature | Watts Nickel Bath | Sulfamate Nickel Bath |

|---|---|---|

| Main Composition | Nickel sulfate, nickel chloride, boric acid | Nickel sulfamate, boric acid |

| Nickel Purity | Lower (may contain more impurities) | High purity, low stress deposits |

| Deposition Rate | Moderate | High, faster plating |

| Internal Stress | Higher internal stress | Low internal stress, ideal for thick deposits |

| Bath pH Range | 4.0 - 5.0 | 3.5 - 4.5 |

| Operating Temperature | 50 - 60degC | 45 - 60degC |

| Applications | General plating, decorative coatings | Electroforming, engineering, wear-resistant coatings |

| Advantages | Lower cost, simpler maintenance | Better ductility, lower stress, high hardness |

| Disadvantages | Higher internal stress, slower plating | More complex chemistry, higher chemical cost |

Overview of Nickel Electroplating Baths

Watts nickel bath, composed of nickel sulfate, nickel chloride, and boric acid, is widely used for its ability to produce hard, bright, and corrosion-resistant nickel coatings. Sulfamate nickel bath, containing nickel sulfamate as the primary source, offers high deposition rates and low internal stress, ideal for thick, ductile, and smooth nickel plating. Both baths are crucial in electroplating, with Watts bath preferred for decorative and general-purpose plating, while sulfamate bath excels in engineering applications requiring wear resistance and precise thickness control.

What Is a Watts Nickel Bath?

A Watts nickel bath is an electrolytic plating solution primarily composed of nickel sulfate, nickel chloride, and boric acid, widely used for nickel electroplating due to its smooth, hard, and corrosion-resistant deposits. Compared to sulfamate nickel baths, which contain nickel sulfamate for stress-reducing plating, Watts baths operate effectively at higher current densities, offering excellent brightness and uniformity but may induce higher internal stresses. Optimal pH control around 4.0 to 4.5 and temperature settings between 45degC and 60degC are critical in Watts nickel baths to maintain plating efficiency and deposit quality.

Key Characteristics of Watts Nickel Bath

Watts nickel bath is characterized by its composition of nickel sulfate, nickel chloride, and boric acid, providing excellent throwing power and uniform deposit thickness on complex shapes. It operates at higher temperatures (around 50degC) and offers superior brightness and hardness compared to sulfamate nickel baths. The Watts bath is ideal for decorative plating requiring smooth, bright finishes, although it may produce higher internal stress than sulfamate baths used primarily for engineering applications.

What Is a Sulfamate Nickel Bath?

A sulfamate nickel bath is an electroplating solution primarily composed of nickel sulfamate, which provides high-purity, low-stress nickel deposits ideal for precision coatings. Compared to Watts nickel baths, sulfamate baths offer superior throwing power and excellent ductility, making them optimal for applications requiring thick, uniform nickel layers. The pH stability and reduced internal stress characteristics of sulfamate nickel baths contribute to enhanced mechanical properties and corrosion resistance in plated components.

Key Characteristics of Sulfamate Nickel Bath

Sulfamate nickel baths are renowned for their low internal stress and superior ductility, making them ideal for applications requiring thick, smooth, and hard coatings. Unlike Watts nickel baths, sulfamate solutions allow for faster plating rates and better throwing power, ensuring uniform deposits even on complex geometries. Their chemical composition, primarily consisting of nickel sulfamate, supports higher current densities while minimizing hydrogen embrittlement and pitting defects.

Watts Nickel vs Sulfamate Nickel: Chemical Composition

Watts nickel bath contains nickel sulfate, nickel chloride, and boric acid, providing a simple and cost-effective electrolyte for nickel plating with moderate hardness and brightness. Sulfamate nickel bath primarily consists of nickel sulfamate, which enables higher current densities and produces deposits with low internal stress, superior ductility, and enhanced corrosion resistance. The chemical composition of sulfamate nickel baths reduces hydrogen embrittlement, making them ideal for applications requiring thick, stress-free coatings compared to the Watts bath.

Differences in Deposit Properties

Watts nickel bath deposits typically exhibit higher internal stress and greater hardness compared to sulfamate nickel bath deposits, which provide superior ductility and better corrosion resistance. Sulfamate baths offer smoother, more uniform coatings ideal for precision components, while Watts baths can produce thicker, more abrasive-resistant layers. Additionally, sulfamate nickel plating tends to have better throwing power and lower hydrogen embrittlement risk, making it preferable for complex geometries.

Applications of Watts vs Sulfamate Nickel Baths

Watts nickel baths are commonly used for decorative plating and corrosion resistance in automotive, aerospace, and electrical components due to their ability to produce hard, bright, and smooth nickel deposits. Sulfamate nickel baths excel in applications requiring high-purity, ductile, and low-stress nickel coatings, such as in electroforming, electronics, and aerospace industries where precise thickness and minimal distortion are critical. The sulfamate bath's adaptability to thick, stress-free deposits makes it ideal for industrial and engineering applications, whereas Watts baths favor aesthetic and corrosion-resistant finishes.

Advantages and Limitations of Each Bath

Watts nickel bath offers superior hardness and good corrosion resistance due to its high nickel and nickel salt concentration but tends to produce a rougher deposit and requires strict temperature control between 40-60degC. Sulfamate nickel bath provides excellent ductility and low internal stress deposits ideal for plating thick layers and complex shapes, with a broader temperature range of 40-65degC, though it is more sensitive to impurities and demands frequent bath maintenance to prevent contamination. Both baths are widely used in electroplating industries, where application-specific requirements dictate the choice based on deposit quality, stress levels, and operating conditions.

Selecting the Right Nickel Bath for Your Process

Watts nickel bath, composed primarily of nickel sulfate, nickel chloride, and boric acid, offers high throwing power and is ideal for plating applications requiring good brightness and hardness. Sulfamate nickel baths provide superior thickness control, excellent ductility, and low internal stress, making them preferable for high-performance engineering parts and thicker deposits. Selecting the right nickel bath depends on the required deposit characteristics, substrate material, and application demands to optimize coating quality and durability.

Watts nickel bath vs sulfamate nickel bath Infographic

materialdif.com

materialdif.com