Nickel coating offers superior corrosion resistance and a smoother, more durable finish compared to zinc coating, making it ideal for high-wear and decorative applications. Zinc coating provides excellent sacrificial protection against rust through galvanization, which is cost-effective and widely used for outdoor metal surfaces. Choosing between nickel and zinc coatings depends on the specific requirements for durability, appearance, and environmental exposure of the metal part.

Table of Comparison

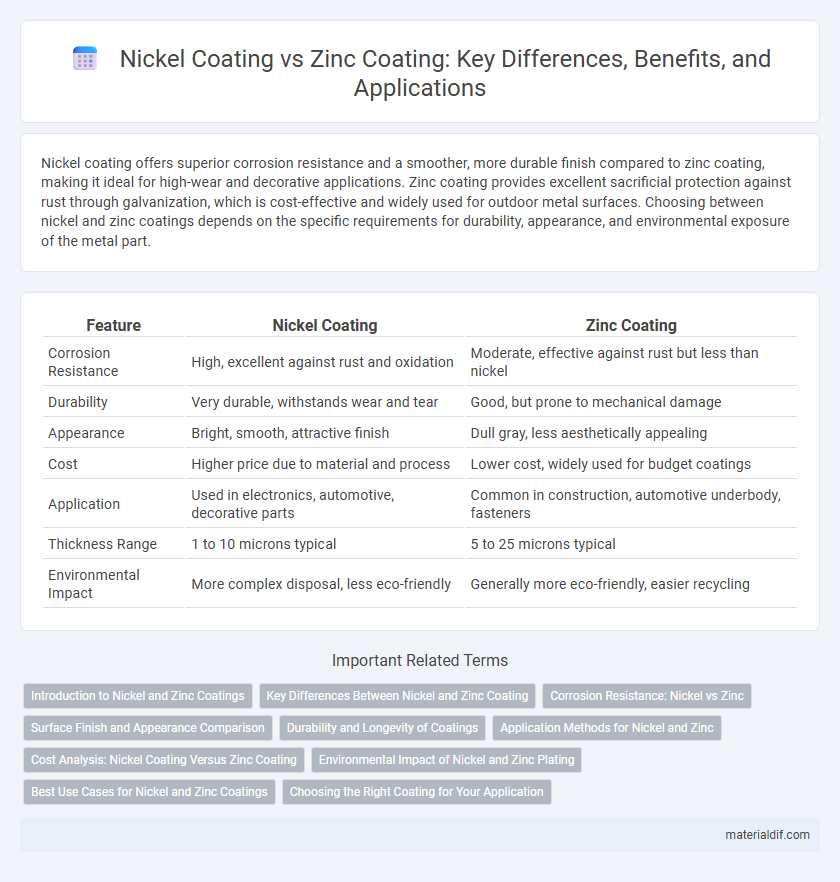

| Feature | Nickel Coating | Zinc Coating |

|---|---|---|

| Corrosion Resistance | High, excellent against rust and oxidation | Moderate, effective against rust but less than nickel |

| Durability | Very durable, withstands wear and tear | Good, but prone to mechanical damage |

| Appearance | Bright, smooth, attractive finish | Dull gray, less aesthetically appealing |

| Cost | Higher price due to material and process | Lower cost, widely used for budget coatings |

| Application | Used in electronics, automotive, decorative parts | Common in construction, automotive underbody, fasteners |

| Thickness Range | 1 to 10 microns typical | 5 to 25 microns typical |

| Environmental Impact | More complex disposal, less eco-friendly | Generally more eco-friendly, easier recycling |

Introduction to Nickel and Zinc Coatings

Nickel coating provides excellent corrosion resistance, wear protection, and a smooth, attractive finish often used in automotive and electronics industries. Zinc coating primarily offers sacrificial protection against rust, making it ideal for steel structures exposed to harsh weather conditions. Both coatings enhance metal durability but differ in application purposes and performance characteristics.

Key Differences Between Nickel and Zinc Coating

Nickel coating offers superior corrosion resistance and hardness compared to zinc coating, making it ideal for high-wear or decorative applications. Zinc coating primarily serves as a sacrificial layer to prevent rust in steel, providing cost-effective but less durable protection. Nickel plating provides a smoother, more uniform finish with enhanced resistance to heat and chemicals, whereas zinc coatings are more prone to chipping and wear under harsh conditions.

Corrosion Resistance: Nickel vs Zinc

Nickel coating offers superior corrosion resistance compared to zinc due to its dense, hard surface that effectively shields metal substrates from oxidation and harsh environments. Zinc coating provides sacrificial protection by corroding first, which is beneficial for steel in less aggressive conditions but may fail faster in highly corrosive or marine environments. The enhanced durability of nickel coatings makes them ideal for applications requiring long-term corrosion protection and aesthetic longevity.

Surface Finish and Appearance Comparison

Nickel coating offers a smoother, brighter, and more reflective surface finish compared to zinc coating, making it ideal for applications requiring enhanced aesthetic appeal and corrosion resistance. Zinc coating typically provides a duller, matte finish with a thicker layer, which is better suited for industrial purposes where protection outweighs appearance. The superior luster and hardness of nickel coatings contribute to improved wear resistance and a more polished look on metal surfaces.

Durability and Longevity of Coatings

Nickel coating provides superior durability and corrosion resistance compared to zinc coating, making it ideal for harsh environments and long-term protection. Zinc coating offers sacrificial protection by corroding first, but its lifespan is generally shorter, especially in aggressive atmospheres. The longevity of nickel coatings extends significantly beyond zinc, often lasting several years without significant wear or deterioration.

Application Methods for Nickel and Zinc

Electrodeposition is a common application method for nickel coating, providing a uniform and corrosion-resistant layer ideal for automotive and electronics components. In contrast, zinc coating primarily employs hot-dip galvanizing, where steel is immersed in molten zinc, creating a thick, durable barrier against rust for construction and infrastructure materials. Both methods enhance metal longevity but differ in process temperature, coating thickness, and industrial usage.

Cost Analysis: Nickel Coating Versus Zinc Coating

Nickel coating generally incurs higher material and application costs compared to zinc coating due to its superior corrosion resistance and aesthetic appeal. Zinc coating offers a more economical solution, primarily used for cost-effective rust prevention in industrial and automotive applications. Evaluating long-term maintenance and lifecycle expenses reveals that nickel coating may offer better value in high-wear or corrosive environments despite its initial premium price.

Environmental Impact of Nickel and Zinc Plating

Nickel coating offers superior corrosion resistance and durability but involves higher environmental concerns due to toxic nickel compounds and energy-intensive processes, often requiring stringent waste management. Zinc coating, commonly used for galvanization, is more environmentally friendly with less hazardous waste and lower energy consumption, yet it provides shorter-term protection against corrosion. Selecting between nickel and zinc plating necessitates balancing environmental impacts with performance needs, emphasizing eco-friendly practices in waste treatment and resource utilization.

Best Use Cases for Nickel and Zinc Coatings

Nickel coating excels in high-wear applications and environments requiring excellent corrosion resistance, such as automotive parts, aerospace components, and industrial machinery. Zinc coating is ideal for protecting steel structures from rust in outdoor and marine environments, commonly used in construction, galvanized steel roofing, and fencing. Choosing nickel coating benefits precision equipment needing smooth, hard surfaces, while zinc coating offers cost-effective, sacrificial protection against corrosion.

Choosing the Right Coating for Your Application

Nickel coating offers superior corrosion resistance and a hard, wear-resistant surface ideal for high-friction applications and harsh environments, outperforming zinc coating in durability and aesthetic appeal. Zinc coating provides excellent sacrificial protection against rust, making it a cost-effective choice for outdoor or structural steel exposed to mild weathering. Selecting the appropriate coating depends on factors such as environmental exposure, required longevity, mechanical stress, and budget, ensuring optimal performance and protection.

Nickel Coating vs Zinc Coating Infographic

materialdif.com

materialdif.com