Mylar offers superior durability and chemical resistance compared to acetate, making it ideal for long-lasting pet film applications. Unlike acetate, Mylar maintains clarity and strength under heat and moisture, ensuring better performance in packaging and insulation. The enhanced dimensional stability of Mylar also provides a more reliable barrier, critical for preserving product freshness and safety.

Table of Comparison

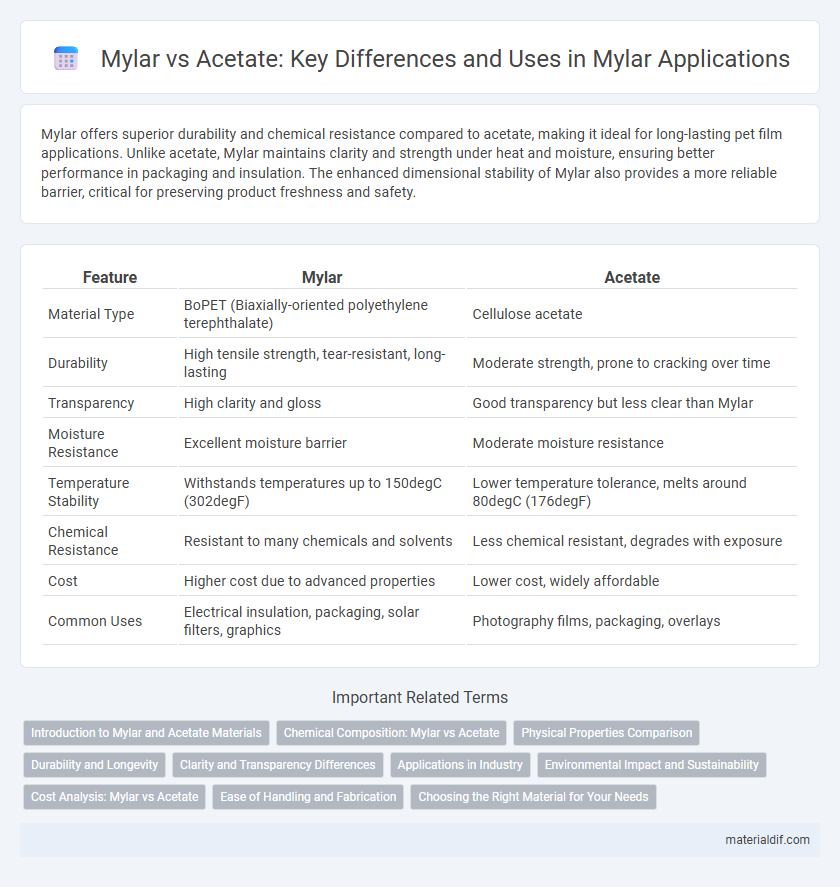

| Feature | Mylar | Acetate |

|---|---|---|

| Material Type | BoPET (Biaxially-oriented polyethylene terephthalate) | Cellulose acetate |

| Durability | High tensile strength, tear-resistant, long-lasting | Moderate strength, prone to cracking over time |

| Transparency | High clarity and gloss | Good transparency but less clear than Mylar |

| Moisture Resistance | Excellent moisture barrier | Moderate moisture resistance |

| Temperature Stability | Withstands temperatures up to 150degC (302degF) | Lower temperature tolerance, melts around 80degC (176degF) |

| Chemical Resistance | Resistant to many chemicals and solvents | Less chemical resistant, degrades with exposure |

| Cost | Higher cost due to advanced properties | Lower cost, widely affordable |

| Common Uses | Electrical insulation, packaging, solar filters, graphics | Photography films, packaging, overlays |

Introduction to Mylar and Acetate Materials

Mylar is a durable polyester film known for its excellent tensile strength, chemical stability, and resistance to moisture, making it ideal for packaging, insulation, and protective applications. Acetate is a cellulose-based film that offers good clarity and flexibility but is less resistant to moisture and mechanical stress compared to Mylar. Both materials serve distinct purposes in film production, with Mylar favored for its longevity and structural integrity while acetate is commonly used in photography, textiles, and archival purposes.

Chemical Composition: Mylar vs Acetate

Mylar is a polyester film made from polyethylene terephthalate (PET), known for its high tensile strength, chemical stability, and resistance to moisture and gases. Acetate film, derived from cellulose acetate, consists of a cellulose base chemically treated with acetic anhydride, making it less resistant to heat and moisture compared to Mylar. The chemical composition of Mylar allows it to maintain dimensional stability and durability under various environmental conditions, whereas acetate's organic cellulose structure tends to degrade more rapidly.

Physical Properties Comparison

Mylar exhibits superior tensile strength and dimensional stability compared to acetate, making it more resistant to stretching and deformation under stress. While Mylar maintains excellent clarity and high resistance to moisture and chemicals, acetate is more prone to yellowing and warping over time. The thermal stability of Mylar also exceeds that of acetate, allowing it to withstand higher temperatures without degrading.

Durability and Longevity

Mylar offers superior durability and longevity compared to acetate due to its polyester composition, which resists tearing, stretching, and environmental degradation. Unlike acetate, Mylar resists moisture, UV light, and temperature fluctuations, making it ideal for long-term archival and industrial applications. This resilience ensures Mylar maintains its structural integrity and clarity over extended periods, outperforming acetate films in durability and lifespan.

Clarity and Transparency Differences

Mylar offers superior clarity and transparency compared to acetate, making it ideal for applications requiring high optical quality such as photographic films and protective overlays. Acetate tends to have a slightly hazier appearance due to its cellulose-based composition, which can reduce light transmission and sharpness. The polyester structure of Mylar provides more consistent transparency and resistance to yellowing over time, ensuring longer-lasting visual clarity.

Applications in Industry

Mylar is widely used in the electronics industry for flexible printed circuit boards and insulation due to its high tensile strength and excellent electrical properties, whereas acetate finds applications mainly in packaging and photographic films because of its biodegradability and affordability. In the food packaging sector, Mylar offers superior barrier protection against moisture, gases, and light, enhancing product shelf life compared to acetate films. Industrial applications also favor Mylar in insulation materials and solar panels, leveraging its durability and resistance to heat, while acetate is preferred for environmentally friendly packaging solutions.

Environmental Impact and Sustainability

Mylar, a brand of biaxially-oriented polyethylene terephthalate (BoPET), offers superior environmental benefits compared to acetate, as it is more durable and recyclable, reducing waste and resource consumption. Unlike acetate, which is biodegradable but requires significant chemical processing and can release harmful substances during decomposition, Mylar's stability ensures longer product lifespan and minimal environmental degradation. Mylar's energy-efficient production and high recyclability align with sustainable manufacturing practices, making it a preferred choice for eco-conscious applications.

Cost Analysis: Mylar vs Acetate

Mylar offers a cost-effective alternative to acetate due to its lower material and production expenses, making it a preferred choice for large-scale applications. While acetate provides higher clarity and better dimensional stability, its higher price point often limits its use to specialized projects. Businesses prioritize Mylar for budget efficiency without significantly compromising quality in most standard use cases.

Ease of Handling and Fabrication

Mylar offers superior ease of handling and fabrication compared to acetate due to its higher tensile strength and flexibility, reducing the risk of tearing or cracking during processing. Its smooth surface enables better adhesion and printing quality, making it ideal for precision applications. Unlike acetate, Mylar resists curling and deformation under heat, simplifying manufacturing workflows in industrial and artistic contexts.

Choosing the Right Material for Your Needs

Mylar offers superior durability, chemical resistance, and dimensional stability compared to acetate, making it ideal for archival storage, insulation, and protective coverings. Acetate is more flexible and easier to print on, often chosen for applications requiring breathability or a softer texture, such as photographic film and overlays. Selecting between Mylar and acetate depends on the specific requirements like longevity, environmental exposure, and mechanical strength needed for your project.

Mylar vs Acetate Infographic

materialdif.com

materialdif.com