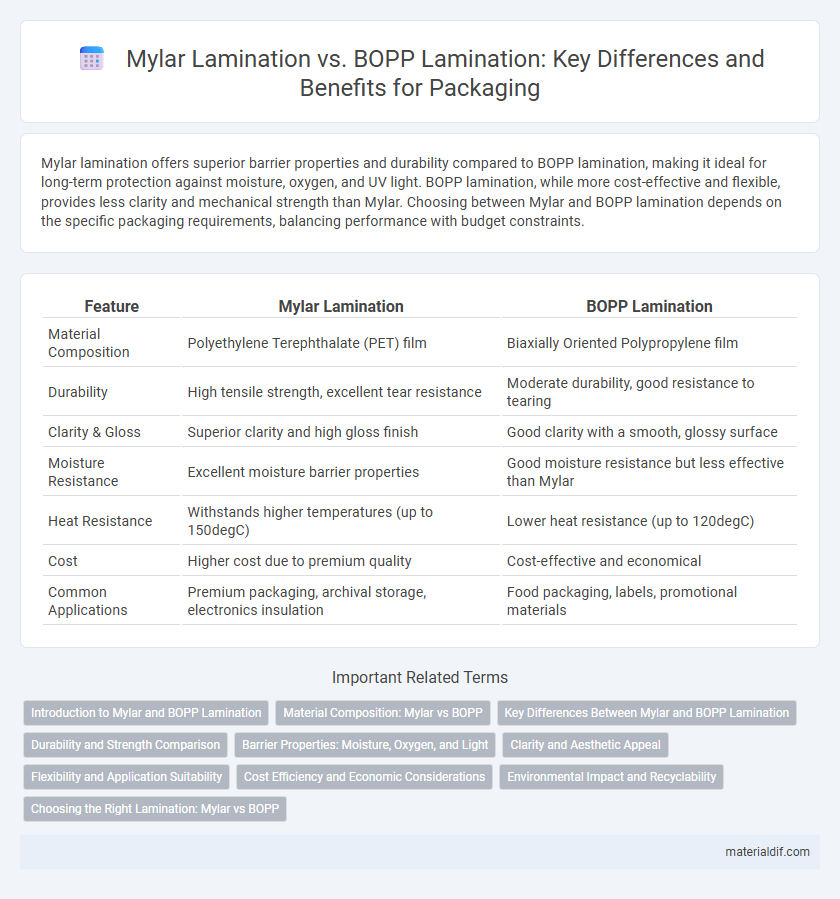

Mylar lamination offers superior barrier properties and durability compared to BOPP lamination, making it ideal for long-term protection against moisture, oxygen, and UV light. BOPP lamination, while more cost-effective and flexible, provides less clarity and mechanical strength than Mylar. Choosing between Mylar and BOPP lamination depends on the specific packaging requirements, balancing performance with budget constraints.

Table of Comparison

| Feature | Mylar Lamination | BOPP Lamination |

|---|---|---|

| Material Composition | Polyethylene Terephthalate (PET) film | Biaxially Oriented Polypropylene film |

| Durability | High tensile strength, excellent tear resistance | Moderate durability, good resistance to tearing |

| Clarity & Gloss | Superior clarity and high gloss finish | Good clarity with a smooth, glossy surface |

| Moisture Resistance | Excellent moisture barrier properties | Good moisture resistance but less effective than Mylar |

| Heat Resistance | Withstands higher temperatures (up to 150degC) | Lower heat resistance (up to 120degC) |

| Cost | Higher cost due to premium quality | Cost-effective and economical |

| Common Applications | Premium packaging, archival storage, electronics insulation | Food packaging, labels, promotional materials |

Introduction to Mylar and BOPP Lamination

Mylar lamination, made from polyester film, offers superior tensile strength, clarity, and chemical resistance compared to BOPP lamination, which uses biaxially oriented polypropylene film known for cost-effectiveness and moisture barrier properties. Mylar's high-temperature resistance and dimensional stability make it ideal for applications requiring durability and clarity, while BOPP excels in packaging due to its lightweight nature and excellent printability. Choosing between Mylar and BOPP lamination depends on specific requirements like durability, clarity, moisture resistance, and budget constraints.

Material Composition: Mylar vs BOPP

Mylar lamination uses polyethylene terephthalate (PET), known for its excellent clarity, durability, and resistance to heat, chemicals, and moisture. BOPP (biaxially oriented polypropylene) lamination consists of polypropylene film stretched in two directions, offering high tensile strength, good gloss, and moisture resistance but lower heat resistance compared to Mylar. The choice between Mylar and BOPP lamination depends on specific application requirements such as barrier properties, durability, and environmental conditions.

Key Differences Between Mylar and BOPP Lamination

Mylar lamination offers superior tensile strength, heat resistance, and dimensional stability compared to BOPP lamination, making it ideal for demanding applications requiring durability and clarity. BOPP lamination, derived from biaxially oriented polypropylene, provides excellent moisture resistance and cost-effectiveness but generally lacks the high-temperature tolerance and rigidity found in Mylar. Key differences include Mylar's enhanced barrier properties, greater chemical resistance, and higher thermal stability, whereas BOPP excels in flexibility and affordability.

Durability and Strength Comparison

Mylar lamination offers superior durability and tensile strength compared to BOPP lamination, making it ideal for high-stress applications requiring resistance to tearing and punctures. Mylar's polyester base provides excellent resistance to moisture, heat, and chemicals, extending product lifespan significantly beyond BOPP films. While BOPP lamination excels in clarity and cost-efficiency, Mylar's enhanced robustness ensures better protection and durability in packaging and industrial uses.

Barrier Properties: Moisture, Oxygen, and Light

Mylar lamination provides superior barrier properties against moisture, oxygen, and light compared to BOPP lamination, making it ideal for preserving product freshness and extending shelf life. The polyester composition of Mylar creates an effective seal that significantly reduces oxygen transmission rates and blocks UV rays, unlike the weaker barrier performance of BOPP films. This enhanced protection makes Mylar the preferred choice for sensitive food and pharmaceutical packaging where controlling environmental exposure is critical.

Clarity and Aesthetic Appeal

Mylar lamination offers superior clarity due to its polyester base, providing a crystal-clear finish that enhances the visual appeal of printed materials. BOPP lamination, made from bi-axially oriented polypropylene, tends to have a slightly hazier appearance, which can dull vibrant colors and intricate details. The high-gloss sheen of Mylar significantly improves aesthetic appeal, making it ideal for premium packaging and high-end product presentations.

Flexibility and Application Suitability

Mylar lamination offers superior flexibility, making it ideal for packaging that requires bending or folding without cracking. BOPP lamination, while less flexible, excels in providing high moisture resistance and clarity for products like food packaging. Choosing between Mylar and BOPP depends largely on the specific application needs, such as durability versus moisture barrier performance.

Cost Efficiency and Economic Considerations

Mylar lamination offers superior durability and chemical resistance, making it ideal for high-end packaging despite a higher initial cost compared to BOPP lamination. BOPP lamination provides a cost-effective solution with good clarity and moisture resistance, suitable for large-scale applications where budget constraints are critical. Economic considerations favor BOPP for volume-driven projects, while Mylar delivers long-term value in premium product protection.

Environmental Impact and Recyclability

Mylar lamination, made from polyester film, offers superior durability and resistance to moisture compared to BOPP lamination, which is derived from polypropylene. In terms of environmental impact, Mylar is more energy-intensive to produce but provides longer-lasting protection, potentially reducing waste through product longevity. Both materials are recyclable, yet BOPP has a broader recycling infrastructure, making it more favorable for sustainable packaging solutions where end-of-life recyclability is a priority.

Choosing the Right Lamination: Mylar vs BOPP

Mylar lamination offers superior clarity, chemical resistance, and durability, making it ideal for premium packaging and archival materials. BOPP lamination provides excellent moisture resistance and cost-effectiveness, suitable for everyday packaging applications such as food wrappers and labels. Choosing between Mylar and BOPP depends on the required barrier properties, budget constraints, and product longevity needs.

Mylar Lamination vs BOPP Lamination Infographic

materialdif.com

materialdif.com