Mylar sheets offer exceptional clarity, lightweight flexibility, and strong moisture resistance, making them ideal for lightweight protective covers and insulation in pet products. Polycarbonate sheets provide superior impact resistance, durability, and thermal stability, which are essential for creating rigid, long-lasting pet enclosures or protective barriers. When choosing between Mylar and polycarbonate sheets for pet-related applications, consider the balance between flexibility and toughness based on your specific durability and use-case requirements.

Table of Comparison

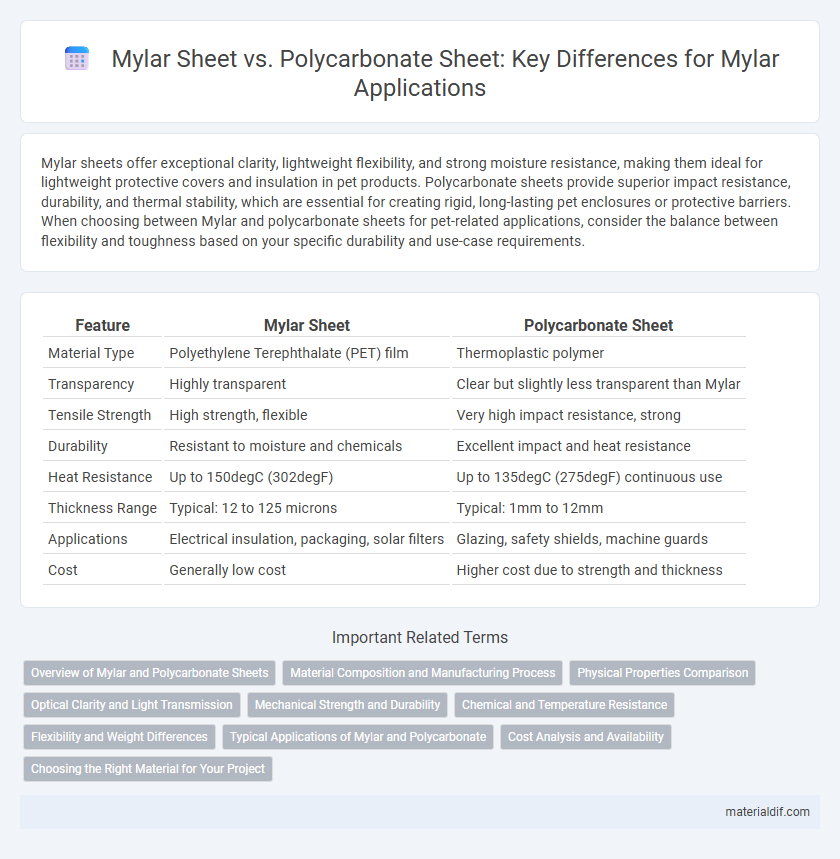

| Feature | Mylar Sheet | Polycarbonate Sheet |

|---|---|---|

| Material Type | Polyethylene Terephthalate (PET) film | Thermoplastic polymer |

| Transparency | Highly transparent | Clear but slightly less transparent than Mylar |

| Tensile Strength | High strength, flexible | Very high impact resistance, strong |

| Durability | Resistant to moisture and chemicals | Excellent impact and heat resistance |

| Heat Resistance | Up to 150degC (302degF) | Up to 135degC (275degF) continuous use |

| Thickness Range | Typical: 12 to 125 microns | Typical: 1mm to 12mm |

| Applications | Electrical insulation, packaging, solar filters | Glazing, safety shields, machine guards |

| Cost | Generally low cost | Higher cost due to strength and thickness |

Overview of Mylar and Polycarbonate Sheets

Mylar sheets are polyester films known for their high tensile strength, chemical stability, and excellent insulating properties, making them ideal for electrical insulation and packaging applications. Polycarbonate sheets offer superior impact resistance, optical clarity, and thermal stability, widely used in construction, automotive, and safety equipment. Both materials provide unique advantages: Mylar excels in flexibility and moisture barrier properties, while polycarbonate delivers enhanced durability and transparency.

Material Composition and Manufacturing Process

Mylar sheets are made from biaxially-oriented polyethylene terephthalate (BoPET), a polyester film known for its high tensile strength and chemical stability, produced through a process of extrusion followed by biaxial stretching. In contrast, polycarbonate sheets consist of a thermoplastic polymer derived from bisphenol A and phosgene, manufactured by polymerization and extrusion or injection molding, resulting in a rigid and impact-resistant material. The distinct molecular structures and production techniques of Mylar and polycarbonate sheets directly influence their physical properties and suitability for applications such as insulation and protective barriers.

Physical Properties Comparison

Mylar sheets exhibit exceptional tensile strength, dimensional stability, and excellent electrical insulation, making them ideal for applications requiring flexibility and durability under varying temperatures. Polycarbonate sheets, in contrast, offer superior impact resistance, higher optical clarity, and greater stiffness but are less resistant to chemical and UV degradation than Mylar. Both materials vary significantly in density and thermal expansion, with Mylar typically having lower density and better resistance to moisture absorption compared to polycarbonate.

Optical Clarity and Light Transmission

Mylar sheets offer superior optical clarity with a light transmission rate of approximately 92%, making them ideal for applications requiring high transparency. Polycarbonate sheets provide good clarity but generally transmit around 88% of visible light, slightly less than Mylar. The enhanced light transmission and minimal distortion in Mylar sheets make them preferable for precision optical uses and protective overlays.

Mechanical Strength and Durability

Mylar sheets exhibit high tensile strength and excellent dimensional stability, making them resistant to stretching and tearing under mechanical stress. Polycarbonate sheets offer superior impact resistance and toughness, allowing them to withstand heavy loads and rough handling without cracking. While Mylar excels in flexibility and chemical resistance, polycarbonate sheets are more durable in extreme weather conditions and characterized by higher impact strength.

Chemical and Temperature Resistance

Mylar sheets exhibit exceptional chemical resistance, effectively withstanding exposure to acids, alkalis, and solvents without degradation, while maintaining stability in temperatures ranging from -70degC to 150degC. In contrast, polycarbonate sheets offer good impact resistance but have limited chemical resistance, particularly against solvents and strong alkalis, and their safe operating temperature generally peaks around 115degC. For applications demanding superior chemical inertness and a broader temperature tolerance, Mylar sheets are preferable over polycarbonate sheets.

Flexibility and Weight Differences

Mylar sheets offer superior flexibility compared to polycarbonate sheets, making them ideal for applications requiring bending or folding without cracking. In terms of weight, Mylar is significantly lighter, which enhances portability and ease of installation in lightweight projects. Polycarbonate sheets, while heavier and less flexible, provide greater impact resistance and rigidity for more demanding structural uses.

Typical Applications of Mylar and Polycarbonate

Mylar sheets are widely used in electrical insulation, packaging, and flexible printed circuits due to their excellent dielectric strength, chemical stability, and dimensional stability. Polycarbonate sheets find typical applications in impact-resistant glazing, automotive components, and medical devices because of their superior toughness, transparency, and heat resistance. Both materials serve unique roles in industries requiring durability and performance, with Mylar favored for lightweight barrier films and Polycarbonate for structural protection.

Cost Analysis and Availability

Mylar sheets generally offer a more cost-effective option compared to polycarbonate sheets due to lower raw material and manufacturing expenses, making them ideal for budget-conscious projects. Availability of Mylar sheets is widespread across various sizes and thicknesses in both retail and industrial markets, whereas polycarbonate sheets, while also readily available, might have higher lead times and costs associated with specialty grades or thicker options. The cost difference combined with easy accessibility positions Mylar sheets as a preferred choice for applications requiring flexibility and affordability without sacrificing essential durability.

Choosing the Right Material for Your Project

Mylar sheets offer excellent tensile strength and chemical resistance, making them ideal for applications requiring flexibility and durability, such as insulation and protective coverings. Polycarbonate sheets provide superior impact resistance and optical clarity, suitable for structural glazing, safety shields, and outdoor use where toughness and transparency are critical. Selecting between Mylar and polycarbonate depends on project needs like flexibility, strength, transparency, and environmental exposure.

Mylar Sheet vs Polycarbonate Sheet Infographic

materialdif.com

materialdif.com