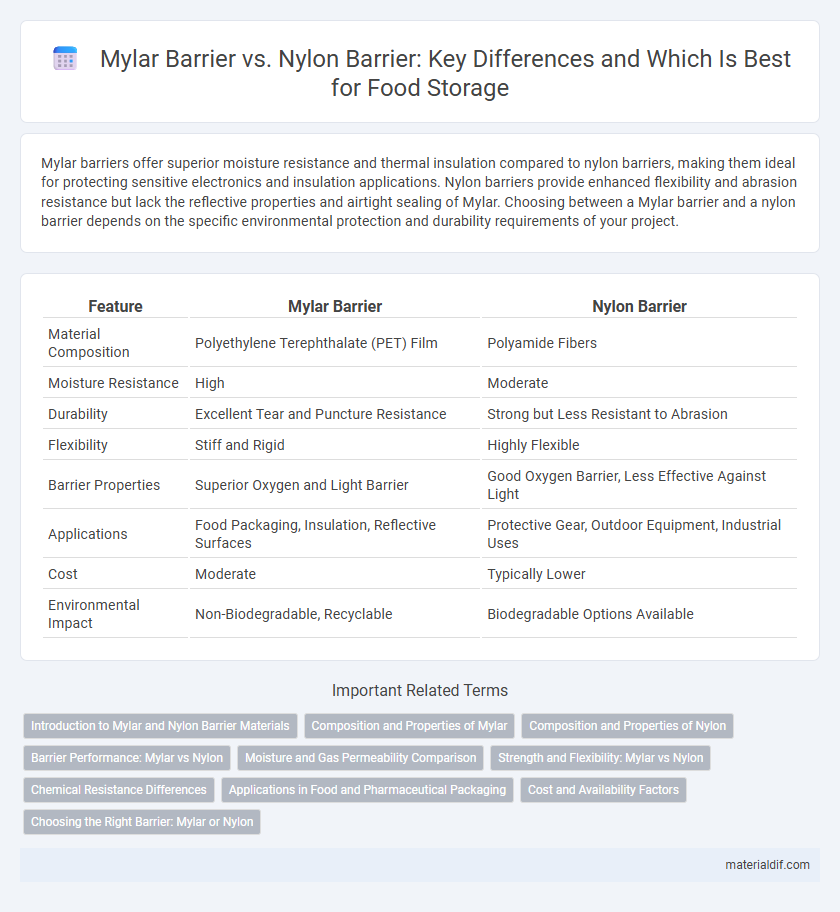

Mylar barriers offer superior moisture resistance and thermal insulation compared to nylon barriers, making them ideal for protecting sensitive electronics and insulation applications. Nylon barriers provide enhanced flexibility and abrasion resistance but lack the reflective properties and airtight sealing of Mylar. Choosing between a Mylar barrier and a nylon barrier depends on the specific environmental protection and durability requirements of your project.

Table of Comparison

| Feature | Mylar Barrier | Nylon Barrier |

|---|---|---|

| Material Composition | Polyethylene Terephthalate (PET) Film | Polyamide Fibers |

| Moisture Resistance | High | Moderate |

| Durability | Excellent Tear and Puncture Resistance | Strong but Less Resistant to Abrasion |

| Flexibility | Stiff and Rigid | Highly Flexible |

| Barrier Properties | Superior Oxygen and Light Barrier | Good Oxygen Barrier, Less Effective Against Light |

| Applications | Food Packaging, Insulation, Reflective Surfaces | Protective Gear, Outdoor Equipment, Industrial Uses |

| Cost | Moderate | Typically Lower |

| Environmental Impact | Non-Biodegradable, Recyclable | Biodegradable Options Available |

Introduction to Mylar and Nylon Barrier Materials

Mylar is a polyester film known for its exceptional tensile strength, chemical stability, and reflective properties, making it ideal for high-performance barrier applications. Nylon barriers offer superior puncture resistance and excellent moisture vapor transmission control, providing enhanced durability in flexible packaging. Both materials serve crucial roles in protecting contents, with Mylar excelling in reflective insulation and nylon optimized for mechanical protection.

Composition and Properties of Mylar

Mylar is a polyester film made from stretched polyethylene terephthalate (PET), known for its superior tensile strength, chemical stability, and reflective properties compared to nylon barriers. Unlike nylon, which is a polyamide and prone to moisture absorption, Mylar maintains low permeability to gases and moisture, making it an excellent choice for insulation and vapor barriers. The high tensile strength and dimensional stability of Mylar contribute to its durability and effectiveness in applications requiring moisture resistance and reflective insulation.

Composition and Properties of Nylon

Nylon barriers consist of synthetic polyamide fibers known for their high tensile strength, flexibility, and resistance to abrasion, making them suitable for applications requiring durability. Unlike Mylar, which is a polyester film with excellent moisture and gas barrier properties, nylon offers better impact resistance and puncture toughness but generally allows more gas permeability. The hygroscopic nature of nylon can affect its performance in high humidity, whereas Mylar maintains consistent barrier properties under varying environmental conditions.

Barrier Performance: Mylar vs Nylon

Mylar exhibits superior barrier performance compared to nylon, providing exceptional resistance to moisture, oxygen, and gases due to its dense polyester film structure. This high impermeability makes Mylar ideal for packaging sensitive products requiring extended shelf life and protection from environmental contaminants. In contrast, nylon offers good mechanical strength but generally allows higher permeability, making it less effective than Mylar for critical barrier applications.

Moisture and Gas Permeability Comparison

Mylar barriers exhibit significantly lower moisture and gas permeability compared to nylon barriers, making them highly effective for preserving product freshness and extending shelf life. The polyester composition of Mylar creates an excellent molecular seal that restricts water vapor and oxygen transmission more efficiently than the polyamide structure of nylon. This enhanced barrier property makes Mylar the preferred choice in sensitive packaging applications requiring superior moisture resistance and oxygen barrier performance.

Strength and Flexibility: Mylar vs Nylon

Mylar barriers offer exceptional tensile strength and resistance to punctures, making them highly durable for long-term applications. Nylon barriers, while also strong, provide greater flexibility and elasticity, allowing them to withstand repeated bending and stretching without tearing. The choice between Mylar and Nylon barriers depends on whether strength or flexibility is prioritized for the specific use case.

Chemical Resistance Differences

Mylar barrier films exhibit superior chemical resistance compared to nylon barriers, effectively preventing permeation of solvents, oils, and acidic substances. While nylon barriers offer good mechanical strength and flexibility, they are more susceptible to degradation when exposed to aggressive chemicals and moisture. Mylar's unique polyester composition provides enhanced stability in harsh chemical environments, making it ideal for applications requiring prolonged resistance to corrosive agents.

Applications in Food and Pharmaceutical Packaging

Mylar barriers provide superior oxygen and moisture resistance compared to nylon barriers, making them ideal for extending shelf life in food packaging such as snack foods, coffee, and dried fruits. Nylon barriers offer excellent puncture resistance and flexibility, which is critical for pharmaceutical packaging requiring durability and protection against physical damage during transport. The combination of Mylar's inertness and nylon's mechanical strength delivers optimized preservation and safety for sensitive products in both industries.

Cost and Availability Factors

Mylar barriers generally cost less than nylon barriers due to lower material and manufacturing expenses, making them a budget-friendly option for insulation and protective applications. Availability of Mylar is widespread since it is a common polyester film used across various industries, ensuring easy procurement and consistent supply. In contrast, nylon barriers often come at a higher price and may face supply constraints because of more complex production processes and specialized uses.

Choosing the Right Barrier: Mylar or Nylon

Mylar barriers offer superior reflective properties and moisture resistance, making them ideal for insulation and light control applications, whereas nylon barriers provide enhanced durability and breathability suitable for industrial and outdoor environments. When choosing between Mylar and nylon, consider factors such as thermal insulation needs, environmental exposure, and mechanical stress. Optimal barrier selection depends on balancing reflective efficiency against strength and flexibility for specific project requirements.

Mylar Barrier vs Nylon Barrier Infographic

materialdif.com

materialdif.com