Mylar labeling offers superior durability and moisture resistance compared to paper labeling, making it ideal for long-term pet products. The glossy finish of Mylar labels enhances color vibrancy and print clarity, ensuring that brand information remains legible over time. Unlike paper labels, Mylar labels resist tearing and fading, providing a more professional and lasting presentation for pet items.

Table of Comparison

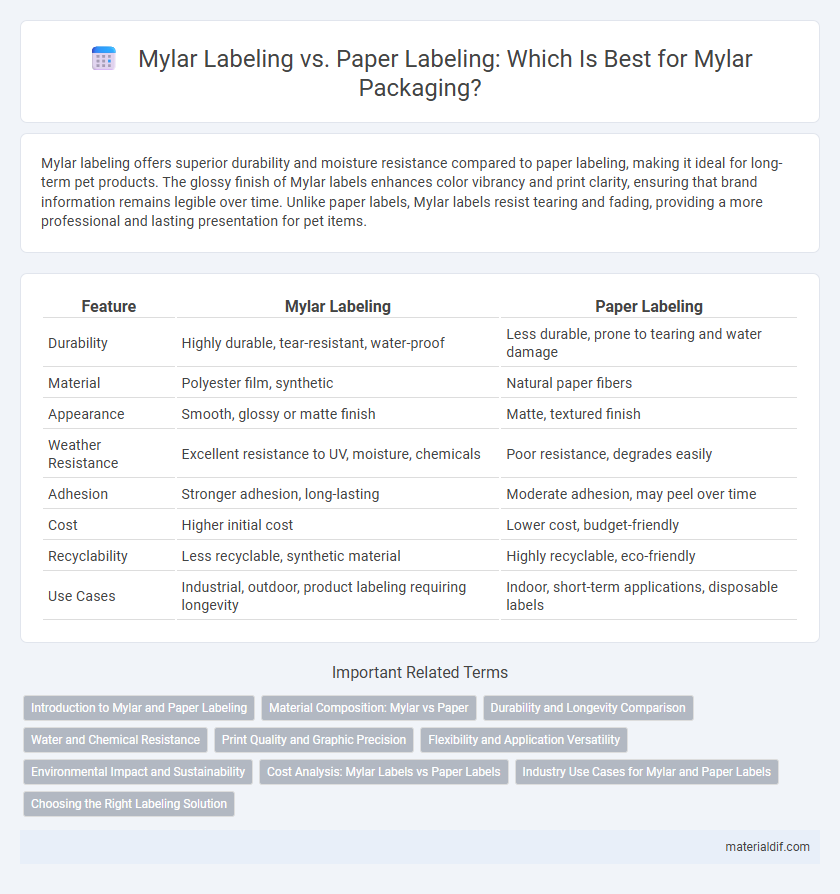

| Feature | Mylar Labeling | Paper Labeling |

|---|---|---|

| Durability | Highly durable, tear-resistant, water-proof | Less durable, prone to tearing and water damage |

| Material | Polyester film, synthetic | Natural paper fibers |

| Appearance | Smooth, glossy or matte finish | Matte, textured finish |

| Weather Resistance | Excellent resistance to UV, moisture, chemicals | Poor resistance, degrades easily |

| Adhesion | Stronger adhesion, long-lasting | Moderate adhesion, may peel over time |

| Cost | Higher initial cost | Lower cost, budget-friendly |

| Recyclability | Less recyclable, synthetic material | Highly recyclable, eco-friendly |

| Use Cases | Industrial, outdoor, product labeling requiring longevity | Indoor, short-term applications, disposable labels |

Introduction to Mylar and Paper Labeling

Mylar labeling offers superior durability and resistance to moisture, chemicals, and temperature fluctuations compared to traditional paper labeling, making it ideal for harsh environments. Paper labeling, while cost-effective and versatile for general applications, tends to degrade quickly when exposed to water or abrasion. Choosing Mylar ensures long-lasting, high-quality labels that maintain clarity and adhesion over time, enhancing product identification and branding.

Material Composition: Mylar vs Paper

Mylar labeling utilizes biaxially-oriented polyethylene terephthalate (BoPET), a synthetic polyester film known for its durability, tear resistance, and resistance to moisture and chemicals. Paper labeling, composed mainly of cellulose fibers, offers biodegradability and ease of printing but lacks the water and tear resistance properties found in Mylar. The superior material composition of Mylar ensures longer-lasting labels that maintain clarity and adhesion under harsh environmental conditions compared to traditional paper labels.

Durability and Longevity Comparison

Mylar labeling offers superior durability compared to paper labeling due to its resistance to moisture, chemicals, and tearing, making it ideal for harsh environments. Its longevity significantly exceeds paper labels, which tend to degrade quickly when exposed to water and UV light. As a result, Mylar labels maintain color vibrancy and legibility over extended periods, reducing the need for frequent replacements in industrial and outdoor applications.

Water and Chemical Resistance

Mylar labeling offers superior water and chemical resistance compared to traditional paper labeling, making it ideal for harsh environments and prolonged use. Its polyester composition provides excellent durability against moisture, oils, and solvents, ensuring labels remain intact and legible. Paper labels often degrade quickly under exposure to water and chemicals, leading to frequent replacement and increased costs.

Print Quality and Graphic Precision

Mylar labeling offers superior print quality due to its smooth, non-porous surface that enhances ink adherence and vibrancy compared to traditional paper labels. The high graphic precision achievable with Mylar ensures sharp, detailed images and text, making it ideal for branding and product identification where clarity is critical. Unlike paper labels, Mylar labels resist smudging and fading, maintaining visual integrity even under harsh environmental conditions.

Flexibility and Application Versatility

Mylar labeling offers superior flexibility and durability compared to traditional paper labeling, making it ideal for applications requiring resistance to moisture, chemicals, and temperature variations. Mylar's versatile material properties enable its use across diverse industries such as electronics, automotive, and food packaging, where long-term adhesion and clarity are critical. In contrast, paper labels are prone to tearing and degradation, limiting their effectiveness in dynamic or harsh environments.

Environmental Impact and Sustainability

Mylar labeling offers superior environmental benefits compared to traditional paper labeling due to its durability and resistance to moisture, reducing the need for frequent replacements and minimizing waste. Mylar's recyclable properties and longer lifespan contribute to lower environmental impact by conserving resources and reducing landfill contributions. In contrast, paper labels often require more frequent disposal and may involve higher deforestation rates, making Mylar a more sustainable choice in labeling solutions.

Cost Analysis: Mylar Labels vs Paper Labels

Mylar labels typically incur a higher upfront cost compared to paper labels due to their durable polyester film composition and enhanced resistance to moisture and chemicals. However, the long-term cost-effectiveness emerges from Mylar's superior durability, reducing replacement frequency and minimizing damage-related expenses. In contrast, paper labels are less expensive initially but often require more frequent re-labeling in harsh environments, increasing overall operational costs.

Industry Use Cases for Mylar and Paper Labels

Mylar labels offer superior durability, chemical resistance, and temperature tolerance, making them ideal for industrial applications such as automotive parts, electronics, and chemical containers where longevity and toughness are critical. In contrast, paper labels are cost-effective and suitable for short-term applications like retail packaging, shipping labels, and inventory tagging, where environmental exposure is minimal. Industries requiring permanent, high-performance identification often prefer Mylar due to its ability to withstand harsh conditions without degradation.

Choosing the Right Labeling Solution

Mylar labeling offers superior durability, water resistance, and chemical resistance compared to traditional paper labeling, making it ideal for harsh environments and long-lasting applications. Paper labeling is cost-effective and offers high print clarity but lacks the robustness required for exposure to moisture or abrasion. Choosing the right labeling solution depends on the specific requirements of durability, environmental exposure, and budget constraints.

Mylar Labeling vs Paper Labeling Infographic

materialdif.com

materialdif.com