Reflective Mylar offers superior light reflectance, enhancing growth environments by maximizing available light for plants. Matte Mylar reduces glare and hot spots, providing more even light distribution that prevents light burn and promotes consistent plant development. Choosing between reflective and matte Mylar depends on whether high reflectivity or uniform light diffusion best suits the specific cultivation needs.

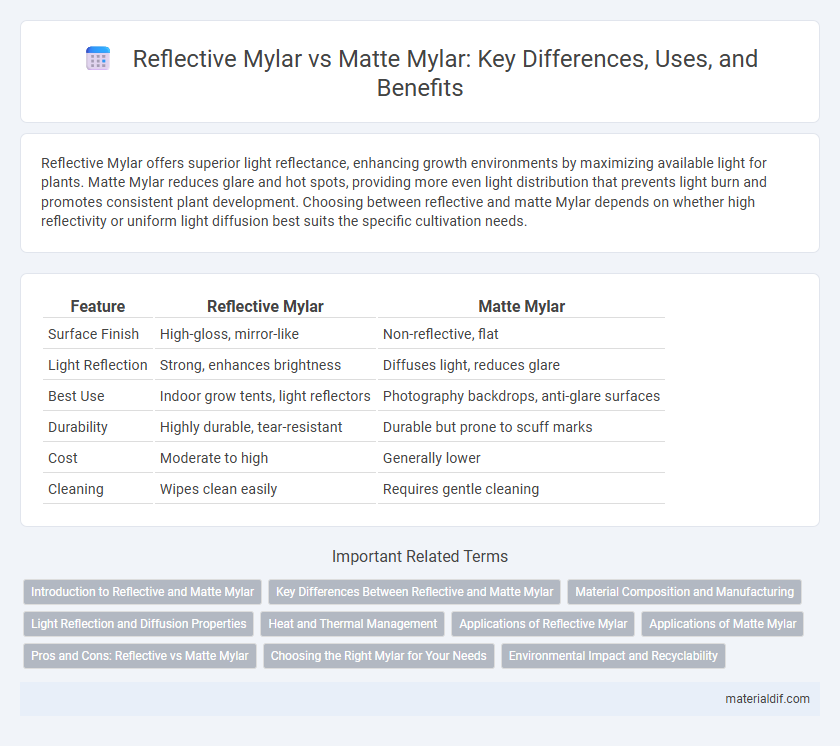

Table of Comparison

| Feature | Reflective Mylar | Matte Mylar |

|---|---|---|

| Surface Finish | High-gloss, mirror-like | Non-reflective, flat |

| Light Reflection | Strong, enhances brightness | Diffuses light, reduces glare |

| Best Use | Indoor grow tents, light reflectors | Photography backdrops, anti-glare surfaces |

| Durability | Highly durable, tear-resistant | Durable but prone to scuff marks |

| Cost | Moderate to high | Generally lower |

| Cleaning | Wipes clean easily | Requires gentle cleaning |

Introduction to Reflective and Matte Mylar

Reflective Mylar features a glossy, mirror-like surface that enhances light reflection and brightness, making it ideal for applications like grow rooms, photography backdrops, and insulation. Matte Mylar offers a non-reflective, soft surface that diffuses light evenly to reduce glare and hotspots, often preferred in spaces requiring subtle light distribution or aesthetic moderation. Understanding the key differences in surface texture and light behavior between Reflective and Matte Mylar informs their optimal use for specific visual or functional requirements.

Key Differences Between Reflective and Matte Mylar

Reflective Mylar features a shiny, mirror-like surface that enhances light reflection, making it ideal for applications requiring maximum brightness and visibility. Matte Mylar has a non-glossy, diffused finish that minimizes glare and reflections, providing a softer appearance suitable for photography backdrops and projection screens. The key differences lie in their surface texture, light reflection properties, and ideal use cases for either highly reflective environments or reduced glare conditions.

Material Composition and Manufacturing

Reflective Mylar is typically made from biaxially oriented polyethylene terephthalate (BoPET) coated with a thin layer of aluminum, which enhances its reflective properties through vacuum metallization techniques. Matte Mylar, also composed of BoPET, features a diffused surface finish achieved by micro-embossing or sandblasting during manufacturing, reducing glare by scattering light. Both types rely on precise polymer stretching and coating processes but differ significantly in surface treatment that dictates their light reflection and diffusion characteristics.

Light Reflection and Diffusion Properties

Reflective Mylar features a highly polished surface that maximizes light reflection, making it ideal for applications requiring intense brightness and minimal light loss. Matte Mylar offers superior light diffusion by scattering light evenly, reducing glare and hotspots for a more uniform illumination. These distinct optical properties dictate their use in environments where either concentrated reflection or gentle light distribution is necessary.

Heat and Thermal Management

Reflective Mylar excels in heat and thermal management by reflecting up to 97% of radiant heat, making it ideal for insulation and temperature control applications. Matte Mylar, while less reflective, offers better diffusion of light and reduces glare, making it suitable when even heat distribution is preferred over high reflectivity. Choosing between Reflective Mylar and Matte Mylar depends on whether maximum heat reflection or controlled thermal diffusion is the priority in the specific application.

Applications of Reflective Mylar

Reflective Mylar excels in applications requiring high light reflectivity and energy efficiency, such as in grow rooms, insulation, and solar panel surfaces. Its mirror-like finish enhances light distribution by reflecting up to 98% of available light, improving plant growth and thermal regulation. This material is also used in emergency blankets and packaging for its superior heat retention and protective properties.

Applications of Matte Mylar

Matte Mylar excels in applications requiring glare reduction and improved visibility under bright lighting, such as in signage, photo framing, and projection screens. Its non-reflective surface minimizes harsh reflections, making it ideal for use in environments like galleries and exhibitions where preserving visual clarity is essential. The material's durability and light diffusion properties also make it suitable for packaging and protective covers.

Pros and Cons: Reflective vs Matte Mylar

Reflective Mylar offers superior light reflectivity up to 97%, ideal for maximizing light efficiency in grow rooms or insulation applications, but it can cause glare and uneven light dispersion. Matte Mylar reduces glare and hotspots with its diffused surface, providing more uniform light distribution, though it reflects less light overall, typically around 88-92%. Choosing between Reflective and Matte Mylar depends on prioritizing maximum reflectivity versus minimizing glare and achieving softer light diffusion.

Choosing the Right Mylar for Your Needs

Reflective Mylar offers high light reflectivity up to 95%, making it ideal for maximizing light efficiency in grow rooms and photography setups. Matte Mylar, with its diffuse reflection properties, reduces hotspots and glare, providing more even light distribution for delicate plants or detailed imaging. Selecting the right Mylar depends on balancing desired light intensity with uniformity based on specific environmental and application requirements.

Environmental Impact and Recyclability

Reflective Mylar, made from biaxially-oriented polyethylene terephthalate (BoPET), has a higher environmental impact due to energy-intensive metallization processes, resulting in lower recyclability compared to Matte Mylar. Matte Mylar, which lacks reflective coatings, offers improved recyclability and reduced ecological footprint because it avoids metal-based layers and can be recycled more easily in standard plastic waste streams. Choosing Matte Mylar supports sustainability through decreased chemical use and enhanced compatibility with existing recycling infrastructure.

Reflective Mylar vs Matte Mylar Infographic

materialdif.com

materialdif.com