Mylar offers superior moisture and oxygen barrier properties compared to polyethylene, making it an ideal choice for pet packaging that requires extended freshness and protection. While polyethylene is flexible and cost-effective, Mylar's durability and resistance to heat and punctures provide enhanced safety for sensitive pet products. Choosing Mylar ensures better preservation of pet food quality and longer shelf life.

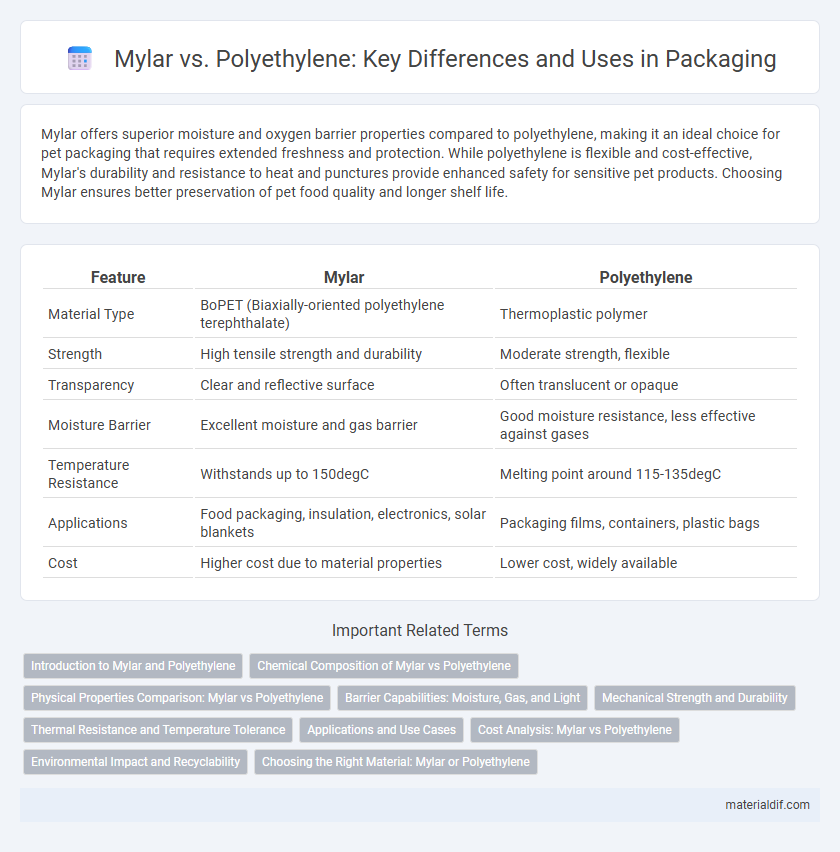

Table of Comparison

| Feature | Mylar | Polyethylene |

|---|---|---|

| Material Type | BoPET (Biaxially-oriented polyethylene terephthalate) | Thermoplastic polymer |

| Strength | High tensile strength and durability | Moderate strength, flexible |

| Transparency | Clear and reflective surface | Often translucent or opaque |

| Moisture Barrier | Excellent moisture and gas barrier | Good moisture resistance, less effective against gases |

| Temperature Resistance | Withstands up to 150degC | Melting point around 115-135degC |

| Applications | Food packaging, insulation, electronics, solar blankets | Packaging films, containers, plastic bags |

| Cost | Higher cost due to material properties | Lower cost, widely available |

Introduction to Mylar and Polyethylene

Mylar, a polyester film known for its high tensile strength, chemical stability, and reflective properties, offers superior durability and temperature resistance compared to polyethylene. Polyethylene, a widely used thermoplastic polymer, is valued for its flexibility, moisture resistance, and cost-effectiveness in packaging and insulation applications. Understanding the distinctions between Mylar's enhanced structural integrity and polyethylene's versatile adaptability is key for selecting the ideal material in industrial and commercial uses.

Chemical Composition of Mylar vs Polyethylene

Mylar is a brand name for biaxially-oriented polyethylene terephthalate (BoPET), a polyester film made from polyethylene terephthalate (PET) resin, whereas polyethylene is a polymer composed of long chains of ethylene monomers. The chemical composition of Mylar includes repeating ester groups (-COO-) in its polymer backbone, giving it superior tensile strength, thermal stability, and chemical resistance compared to polyethylene's simpler hydrocarbon chain structure. Mylar's aromatic rings from the terephthalate units provide enhanced barrier properties against gases and moisture, making it ideal for packaging and insulating applications where polyethylene's less complex chemical composition results in lower performance.

Physical Properties Comparison: Mylar vs Polyethylene

Mylar exhibits significantly higher tensile strength and thermal resistance compared to polyethylene, making it ideal for applications requiring durability and heat stability. While polyethylene offers greater flexibility and impact resistance, its lower melting point limits its use in high-temperature environments. The dimensional stability and chemical resistance of Mylar surpass those of polyethylene, providing superior performance in demanding industrial and packaging uses.

Barrier Capabilities: Moisture, Gas, and Light

Mylar exhibits superior barrier capabilities compared to polyethylene, effectively blocking moisture, oxygen, and light to preserve product freshness and extend shelf life. The metallized or biaxially oriented polyethylene terephthalate (BoPET) film structure of Mylar provides enhanced resistance to vapor transmission and gas permeability. In contrast, polyethylene offers lower protection against moisture and oxygen ingress, making Mylar the preferred choice for high-barrier packaging applications.

Mechanical Strength and Durability

Mylar, a biaxially-oriented polyethylene terephthalate (BoPET) film, exhibits superior mechanical strength and durability compared to standard polyethylene films, offering enhanced tensile strength and resistance to tearing. Its high dimensional stability and resistance to chemical degradation make Mylar ideal for applications requiring long-lasting performance under stress or environmental exposure. Polyethylene films, while flexible and cost-effective, generally lack the rigidity and endurance found in Mylar, limiting their use in high-strength, durable contexts.

Thermal Resistance and Temperature Tolerance

Mylar, a polyester film, exhibits superior thermal resistance compared to polyethylene, maintaining stability at temperatures up to 150degC (302degF), while polyethylene generally withstands only about 80degC (176degF). This enhanced temperature tolerance makes Mylar ideal for applications requiring heat resistance, such as insulation and industrial packaging. In contrast, polyethylene's lower melting point limits its use to environments with moderate thermal demands.

Applications and Use Cases

Mylar, a polyester film known for its high tensile strength, chemical stability, and excellent electrical insulation properties, is widely used in flexible electronics, packaging, and insulation applications. Polyethylene, characterized by its flexibility, moisture resistance, and low cost, is primarily employed in packaging films, plastic bags, and containers. Mylar's superior durability and temperature resistance make it ideal for specialized uses such as solar panel backings and magnetic tapes, whereas polyethylene excels in disposable and lightweight packaging scenarios.

Cost Analysis: Mylar vs Polyethylene

Mylar typically costs more per square foot compared to polyethylene due to its superior tensile strength and thermal resistance, making it a preferred choice for applications requiring durability. Polyethylene offers a lower upfront cost and is widely used for disposable or short-term products, providing economic advantages in bulk purchases. When evaluating long-term investment, Mylar's resilience can reduce replacement frequency, potentially offsetting the initial higher expenditure compared to polyethylene.

Environmental Impact and Recyclability

Mylar, a polyester film made from polyethylene terephthalate (PET), offers superior recyclability compared to polyethylene due to its widespread acceptance in recycling programs and higher durability, which reduces waste generation. Polyethylene, primarily used in plastic bags and packaging, often faces challenges in recycling because of contamination and lower market value, contributing to greater environmental pollution. The environmental impact of Mylar is mitigated by its ability to be recycled into new films and industrial materials, while polyethylene's degradability issues result in increased landfill accumulation and microplastic pollution.

Choosing the Right Material: Mylar or Polyethylene

Mylar offers superior tensile strength and moisture resistance compared to polyethylene, making it ideal for applications requiring durability and barrier protection. Polyethylene, known for its flexibility and cost-effectiveness, suits packaging where lighter weight and lower expenses are priorities. Selecting between Mylar and polyethylene depends on factors such as required strength, moisture barrier performance, and budget constraints for the specific application.

Mylar vs Polyethylene Infographic

materialdif.com

materialdif.com