Mylar printing offers superior durability and clarity ideal for high-quality labels and packaging, while offset printing excels in large-volume runs with consistent color reproduction and cost-efficiency. Mylar printing provides better resistance to moisture and fading, making it suitable for long-lasting applications. Offset printing remains preferred for traditional paper materials due to faster production times and lower per-unit costs in bulk orders.

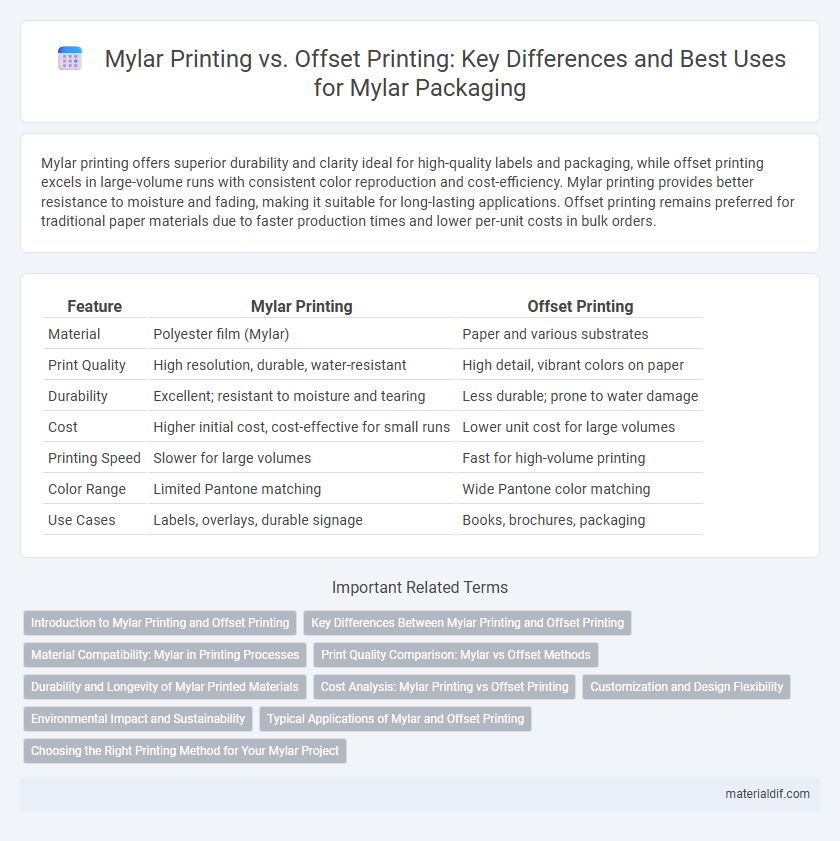

Table of Comparison

| Feature | Mylar Printing | Offset Printing |

|---|---|---|

| Material | Polyester film (Mylar) | Paper and various substrates |

| Print Quality | High resolution, durable, water-resistant | High detail, vibrant colors on paper |

| Durability | Excellent; resistant to moisture and tearing | Less durable; prone to water damage |

| Cost | Higher initial cost, cost-effective for small runs | Lower unit cost for large volumes |

| Printing Speed | Slower for large volumes | Fast for high-volume printing |

| Color Range | Limited Pantone matching | Wide Pantone color matching |

| Use Cases | Labels, overlays, durable signage | Books, brochures, packaging |

Introduction to Mylar Printing and Offset Printing

Mylar printing utilizes polyester film known for its durability, clarity, and resistance to moisture, making it ideal for high-quality graphic prints and technical drawings. Offset printing, a widely used commercial printing technique, transfers ink from a plate to a rubber blanket and then onto paper, offering cost-effective mass production with precise color reproduction. Both methods serve distinct purposes: Mylar printing excels in specialized, long-lasting prints, while offset printing handles large volumes efficiently with consistent output quality.

Key Differences Between Mylar Printing and Offset Printing

Mylar printing utilizes polyester film for high-durability and water-resistant prints, making it ideal for packaging and technical drawings, whereas offset printing employs metal plates and rubber blankets suited for large-volume, cost-effective production. Mylar printing offers superior clarity and dimensional stability but typically involves higher material costs, while offset printing excels in color fidelity and speed for mass print runs. The key differences lie in substrate flexibility, cost efficiency, and application suitability, with Mylar favored for specialized uses and offset preferred for traditional bulk printing needs.

Material Compatibility: Mylar in Printing Processes

Mylar printing excels in material compatibility due to its durability, transparency, and resistance to moisture and chemicals, making it ideal for high-quality, long-lasting prints on plastic substrates. Offset printing, while highly efficient for paper-based materials, often requires specialized inks or surface treatments to adhere properly to Mylar, limiting its versatility with this polymer film. Mylar's unique polyester composition demands printing processes that accommodate its smooth, non-porous surface for optimal ink adhesion and image clarity.

Print Quality Comparison: Mylar vs Offset Methods

Mylar printing delivers sharp, vibrant images with superior detail and color accuracy due to its smooth, non-porous surface, making it ideal for high-resolution graphics and fine line work. Offset printing offers consistent color reproduction and excellent print quality on bulk paper runs but may lack the crispness and durability that Mylar's polyester film provides. The choice between Mylar and offset printing depends on the need for durability and image precision versus cost-efficiency and volume.

Durability and Longevity of Mylar Printed Materials

Mylar printing offers superior durability compared to offset printing due to its synthetic polyester base, which is resistant to moisture, tearing, and UV damage, ensuring long-lasting printed materials. This resilience allows Mylar prints to maintain color vibrancy and structural integrity in harsh environments, significantly extending their lifespan beyond traditional offset prints on paper. Businesses and industries that require durable signage, labels, or documents benefit from Mylar's enhanced longevity, making it a cost-effective choice for frequent use or outdoor applications.

Cost Analysis: Mylar Printing vs Offset Printing

Mylar printing generally incurs higher initial costs due to specialized materials and processes, making it less cost-effective for large-volume runs compared to offset printing. Offset printing benefits from economies of scale, reducing per-unit costs significantly as volume increases. For projects requiring durability and precision on synthetic substrates, the upfront investment in Mylar printing may justify the overall expense despite higher initial outlays.

Customization and Design Flexibility

Mylar printing offers superior customization and design flexibility compared to offset printing, enabling intricate designs with vibrant colors and fine details on durable, glossy surfaces. Mylar's ability to handle variable data printing allows for personalized prints, making it ideal for limited runs and unique designs. Offset printing, while cost-effective for large volumes, lacks the versatility in substrate compatibility and quick design changes that Mylar printing provides.

Environmental Impact and Sustainability

Mylar printing uses polyester film that is recyclable and reduces paper waste compared to offset printing, which relies heavily on paper and chemical-based inks. The low VOC emissions and energy efficiency of Mylar printing contribute to a smaller environmental footprint. Offset printing typically consumes more water and generates more hazardous waste, making Mylar a more sustainable option for eco-conscious printing needs.

Typical Applications of Mylar and Offset Printing

Mylar printing is commonly used for applications requiring durability and transparency, such as technical drawings, architectural blueprints, and reusable stencils, due to Mylar's tear-resistant and dimensional stability properties. Offset printing is favored for high-volume production of brochures, magazines, packaging, and newspapers where color accuracy, sharp detail, and cost-efficiency are critical. Both methods serve distinct needs: Mylar printing excels in specialized, long-lasting prints, while offset printing dominates commercial mass-market materials.

Choosing the Right Printing Method for Your Mylar Project

Mylar printing offers superior durability and flexibility, making it ideal for projects requiring waterproof and tear-resistant materials, while offset printing excels in producing high-volume, cost-effective prints with consistent color accuracy on paper-based substrates. Selecting the appropriate method depends on project specifications such as material type, print volume, and budget constraints; Mylar printing suits specialized applications like banners and labels, whereas offset printing is optimal for large-scale commercial distribution. Understanding the technical differences and performance needs ensures the best printing solution for Mylar projects.

Mylar Printing vs Offset Printing Infographic

materialdif.com

materialdif.com