Mylar embossing raises the design above the surface, creating a visually striking and tactile effect that enhances the texture and depth of pet labels. In contrast, Mylar debossing presses the design into the material, producing a recessed look that offers subtle sophistication and durability against wear. Both techniques improve the aesthetic appeal of Mylar pet products, allowing customization options that blend functionality with unique visual impact.

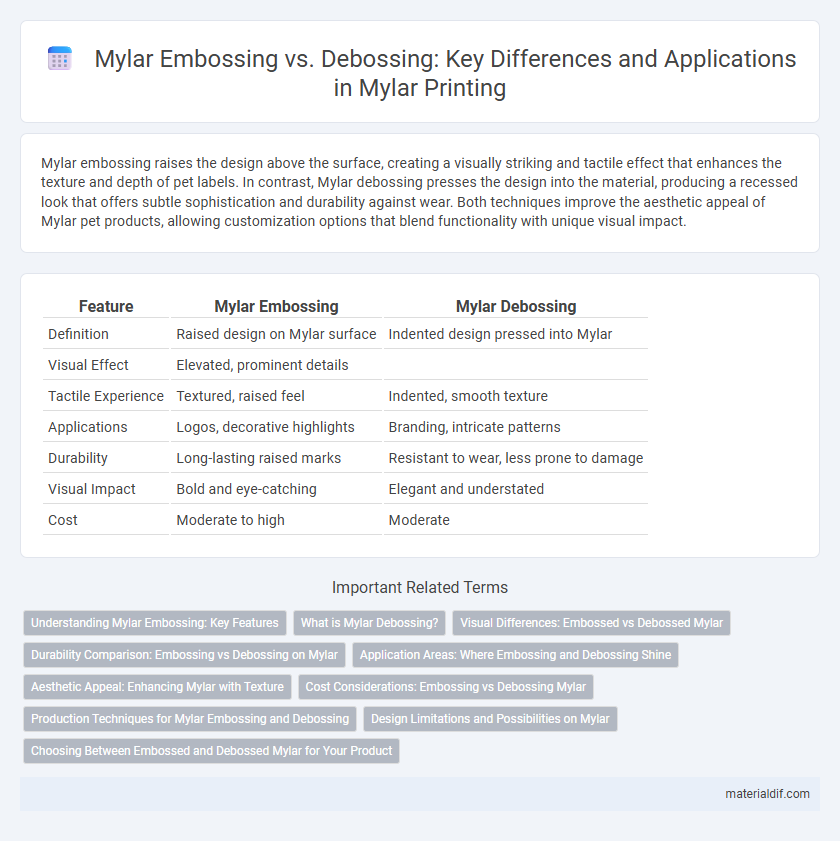

Table of Comparison

| Feature | Mylar Embossing | Mylar Debossing |

|---|---|---|

| Definition | Raised design on Mylar surface | Indented design pressed into Mylar |

| Visual Effect | Elevated, prominent details | |

| Tactile Experience | Textured, raised feel | Indented, smooth texture |

| Applications | Logos, decorative highlights | Branding, intricate patterns |

| Durability | Long-lasting raised marks | Resistant to wear, less prone to damage |

| Visual Impact | Bold and eye-catching | Elegant and understated |

| Cost | Moderate to high | Moderate |

Understanding Mylar Embossing: Key Features

Mylar embossing involves creating raised designs or patterns on Mylar sheets by pressing the material between engraved dies, enhancing texture and visual appeal. This technique provides durability and a professional finish, making it ideal for packaging, labels, and decorative applications. Embossed Mylar clarifies branding elements and adds tactile interest without compromising the polyester film's strength and flexibility.

What is Mylar Debossing?

Mylar debossing is a printing technique that creates recessed designs by pressing an image or pattern into the Mylar surface, resulting in a sunken effect. This method enhances the tactile and visual appeal of product packaging, labels, and decorative items by adding depth and texture without additional ink or foil. Debossing on Mylar is commonly used for luxury branding and securing authenticity through subtle, durable impressions.

Visual Differences: Embossed vs Debossed Mylar

Embossed Mylar features raised designs that create a three-dimensional effect, enhancing texture and visual appeal through elevated patterns visible to the touch and eye. Debossed Mylar, on the other hand, presents recessed impressions that produce a sunken look, offering subtle shadows and depth while maintaining a smooth surface. These visual differences in embossed versus debossed Mylar impact product aesthetics, influencing light reflection, tactile experience, and overall design sophistication.

Durability Comparison: Embossing vs Debossing on Mylar

Embossing on Mylar creates raised designs that enhance surface durability by reducing wear and tear over time, while debossing produces recessed patterns that may be more prone to damage from friction and abrasion. The raised texture of embossing helps protect Mylar from scratches and scuff marks, making it ideal for items requiring long-lasting tactile effects. In contrast, debossing's indentations can collect dirt and degrade faster under frequent handling, impacting the material's overall longevity.

Application Areas: Where Embossing and Debossing Shine

Mylar embossing enhances product packaging, labels, and decorative items by creating raised, tactile surfaces that attract consumer attention and add a premium feel. Debossing on Mylar is ideal for branding on stationery, wallets, and promotional materials where subtle, recessed impressions provide elegant and understated visual appeal. Both techniques excel in luxury goods and gift packaging, leveraging Mylar's durability and reflective qualities to amplify design impact.

Aesthetic Appeal: Enhancing Mylar with Texture

Mylar embossing creates raised textures that add dimensionality and a tactile feel, enhancing visual interest and luxury in packaging and graphic design. Debossing presses designs into the Mylar surface, producing subtle, recessed patterns that offer a refined and understated aesthetic. Both techniques elevate Mylar's aesthetic appeal by introducing texture, making products visually striking and engaging to touch.

Cost Considerations: Embossing vs Debossing Mylar

Embossing Mylar typically incurs higher costs due to the need for raised molds and precise pressure application, which can increase production time and tooling expenses. Debossing Mylar, involving impressions pressed into the surface, generally lowers operational costs thanks to simpler die creation and faster processing. Budget considerations often favor debossing for large-volume runs, while embossing is selected for premium finishes despite its higher cost.

Production Techniques for Mylar Embossing and Debossing

Mylar embossing involves raising designs on the surface by pressing the material between engraved dies and rollers, creating a three-dimensional effect that enhances texture and visual appeal. Debossing, conversely, presses the design into the Mylar film, forming recessed patterns typically achieved with heat and pressure to ensure permanent indentation. Both techniques utilize precise temperature and pressure controls to manipulate Mylar's polyester substrate, optimizing durability and detail in custom packaging, labels, and decorative applications.

Design Limitations and Possibilities on Mylar

Mylar embossing creates raised designs by pressing shapes into the material, enhancing texture and visual depth but limiting fine details due to the thickness and rigidity of Mylar. Debossing, which indents designs into Mylar, allows for subtler effects and more intricate patterns but may reduce durability and contrast. Both techniques require careful consideration of Mylar's flexibility and thickness to optimize design clarity and longevity in applications such as packaging and labeling.

Choosing Between Embossed and Debossed Mylar for Your Product

Choosing between embossed and debossed Mylar depends on the desired tactile and visual effect for your product packaging or branding. Embossing raises the design above the Mylar surface, creating a prominent texture that enhances visibility and luxury appeal, while debossing impresses the design into the material, offering a subtle, elegant indentation that adds sophistication without disrupting the smooth finish. Consider your product's market positioning and customer experience goals to determine whether the elevated depth of embossing or the refined recess of debossing better communicates your brand identity.

Mylar Embossing vs Debossing Infographic

materialdif.com

materialdif.com